GE Power Management

745 Transformer Management Relay

10-3

10 COMMISSIONING

10.2 TEST EQUIPMENT

10

10.2 TEST EQUIPMENT

10.2.1 TEST SETUP

It is possible to completely verify the 745 relay operation using the built-in test and simulation features

described earlier in this manual. However, some customers prefer to perform simple signal-injection tests to

verify the basic operation of each element placed into service. The procedures described in this chapter have

been designed for this purpose. To use the built-in facilities, refer to the appropriate sections in this manual.

The conventional, decades-old approach to testing relays utilized adjustable voltage and current sources, vari-

acs, phase shifters, multimeters, timing device, and the like. In the last few years several instrumentation com-

panies have offered sophisticated instrumentation to test protective relays. Generally this equipment offers

built-in sources of AC voltage and current, DC voltage and current, timing circuit, variable frequency, phase

shifting, harmonic generation, and complex fault simulation. If using such a test set, refer to the equipment

manufacturer's instructions to generate the appropriate signals required by the procedures in this section. If

you do not have a sophisticated test set, then you will need the following "conventional" equipment:

•

Variable current source able to supply up to 40 A (depends on relay settings)

•

Variable power resistors to control current amplitude

•

Ten-turn 2 K

Ω

low-power potentiometer

•

Power rectifier to build a circuit to generate 2nd harmonics

•

Accurate timing device

•

Double-pole single-throw contactor suitable for at least 40 amperes AC.

•

Combined fundamental & 5th-harmonic adjustable current supply for elements involving the 5

th

harmonic.

•

Variable-frequency source of current or voltage to test over/underfrequency and frequency trend elements.

•

Ammeters (RMS-responding), multimeters, voltmeters

•

variable dc mA source

•

variable dc mV source

•

single-pole single-throw contactor

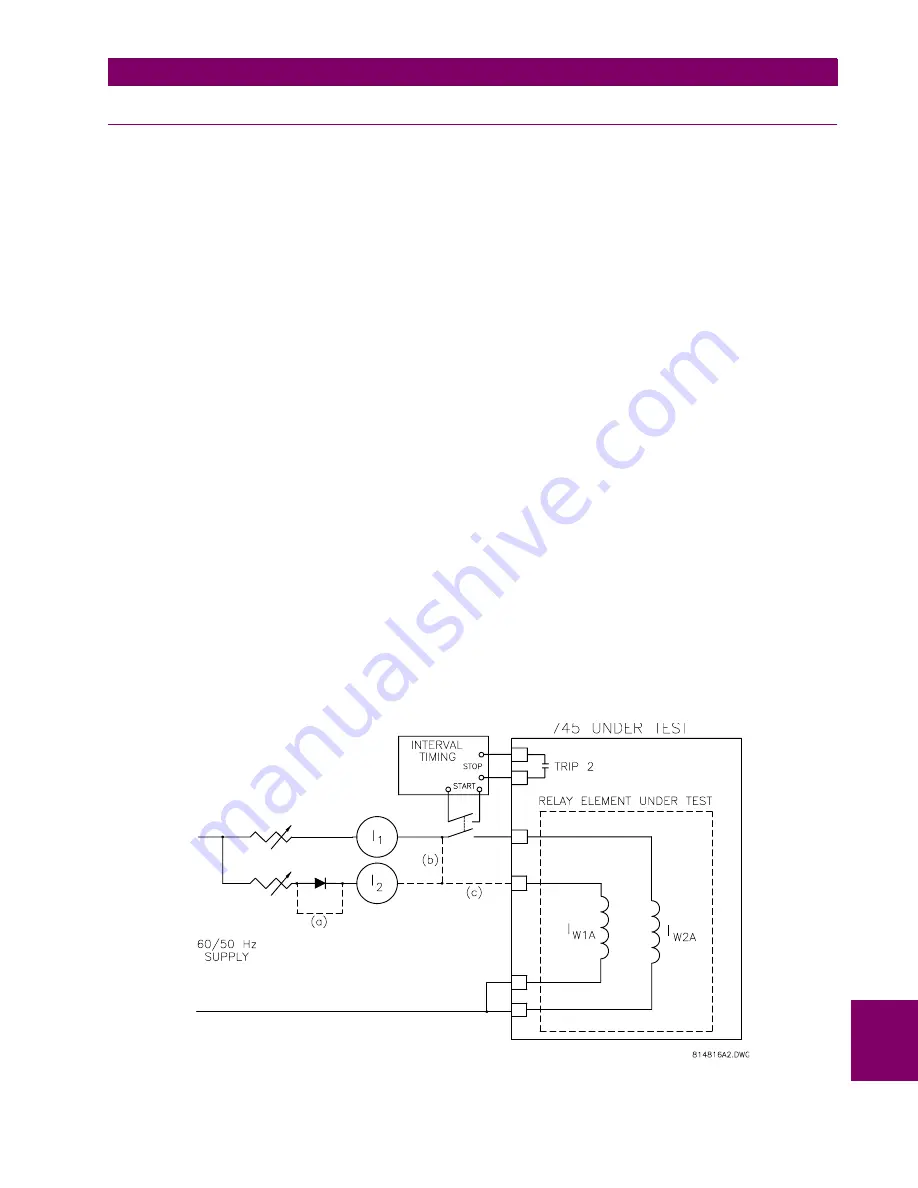

The simple test setup shown below can be used for the majority of tests. When the diode is not shorted and the

two currents are summed together prior to the switch, the composite current contains the 2

nd

harmonic neces-

sary to verify the 2

nd

harmonic restraint of the harmonic restraint percent differential elements. With the diode

shorted and the two currents fed to separate relay inputs, the slope of the differential elements can be mea-

sured. With only

I

1

connected (with a return path) the pickup level of any element can be measured.

Figure 10–1: TEST SETUP

Summary of Contents for 745 TRANSFORMER MANAGEMENT RELAY

Page 30: ...2 8 745 Transformer Management Relay GE Power Management 2 3 SECURITY 2 GETTING STARTED 2 ...

Page 210: ...7 36 745 Transformer Management Relay GE Power Management 7 2 BLOCK DIAGRAMS 7 SCHEME LOGIC 7 ...

Page 322: ...9 12 745 Transformer Management Relay GE Power Management 9 3 USING 745PC 9 745 PC SOFTWARE 9 ...

Page 396: ...A 4 745 Transformer Management Relay GE Power Management A 1 FIGURES AND TABLES APPENDIXA A ...

Page 400: ...C 2 745 Transformer Management Relay GE Power Management C 1 WARRANTY INFORMATION APPENDIXC C ...

Page 406: ...vi 745 Transformer Management Relay GE Power Management ...

Page 407: ...GE Power Management 745 Transformer Management Relay NOTES ...