4–54

869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

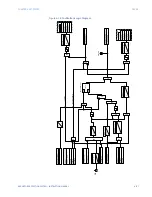

DEVICE

CHAPTER 4: SETPOINTS

LED indicator. By default, this indicator displays the present status of the corresponding

pushbutton (ON or OFF). This can be changed by programming the LED Trigger setting in

the Programmable ED settings menu.

The activation and deactivation of user-programmable pushbuttons is dependent on

whether latched or self-reset mode is programmed.

LATCHED MODE

In Latched Mode, a pushbutton can be set (activated) by directly pressing the associated

front panel pushbutton. The pushbutton maintains the set state until deactivated by a

Reset command or after a user-specified time delay. The state of each pushbutton is

stored in non-volatile memory and maintained through loss of control power.

The pushbutton is Reset (deactivated) in Latched Mode by directly pressing the associated

active front panel pushbutton. It can also be programmed to Reset automatically through

the PB 1 AUTORESET and PB 1 AUTORESET DELAY settings. These settings enable the auto-

reset timer and specify the associated time delay. The auto-reset timer can be used in

select-before-operate (SBO) switching device control applications, where the command

type (CLOSE/OPEN) must be selected prior to command execution. The selection must

Reset automatically if control is not executed within a specified time period.

SELF-RESET MODE

In Self-reset mode, a pushbutton remains active for the time it is pressed (the pulse

duration) plus the Dropout time specified in the PUSHBTN 1 DROPOUT TIME setting. The

pushbutton is Reset (deactivated) in Self-reset mode when the dropout delay specified in

the PUSHBTN 1 DROPOUT TIME setting expires.The pulse duration of the pushbutton must

be at least 50 ms to operate the pushbutton. This allows the user-programmable

pushbuttons to properly operate during power cycling events and various system

disturbances that may cause transient assertion of the operating signals.

The operation of each user-programmable pushbutton can be inhibited through the

PUSHBTN 1 LOCK setting. If locking is applied, the pushbutton ignores the commands

executed through the front panel pushbuttons. The locking functions are not applied to the

auto-reset feature. In this case, the inhibit function can be used in SBO control operations

to prevent the pushbutton function from being activated and ensuring “one-at-a-time”

select operation.

The locking functions can also be used to prevent accidental pressing of the front panel

pushbuttons.

Pushbutton states can be logged by the Event Recorder and displayed as Target

Messages. In latched mode, user-defined messages can also be associated with each

pushbutton and displayed when the pushbutton is ON or changing to OFF.

Path

:

Setpoints > Device > Programmable PBs > Pushbutton 1(X)

FUNCTION

Range: Self-reset, Latched, Disabled

Default: Self-reset

This setting selects the characteristic of the pushbutton. If set to “Disabled” the

pushbutton is not active and the corresponding FlexLogic operands (both ON and OFF)

are de-asserted. If set to

Self-reset

the control logic is activated by the pulse (longer

than 100 ms) issued when the pushbutton is being physically pressed.

When in

Self-reset

mode and activated locally, the pushbutton control logic asserts the

ON corresponding FlexLogic operand as long as the pushbutton is being physically

pressed, and after being released the deactivation of the operand is delayed by the

PUSHBTN 1 DROPOUT TIME setting. The OFF operand is asserted when the pushbutton

element is deactivated.

If set to

Latched

the control logic alternates the state of the corresponding FlexLogic

operand between ON and OFF on each button press or by virtually activating the

pushbutton (assigning Set and Reset operands). When in

Latched

mode, the states of

Summary of Contents for 869

Page 10: ...VIII 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL ...

Page 127: ...CHAPTER 3 INTERFACES SOFTWARE INTERFACE 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL 3 49 ...

Page 129: ...CHAPTER 3 INTERFACES SOFTWARE INTERFACE 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL 3 51 ...

Page 538: ...4 406 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL TESTING CHAPTER 4 SETPOINTS ...

Page 578: ...6 22 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL FLEXELEMENTS CHAPTER 6 METERING ...

Page 592: ...7 14 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL CLEAR RECORDS CHAPTER 7 RECORDS ...