CHAPTER 4: SETPOINTS

MONITORING

869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

4–301

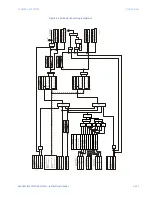

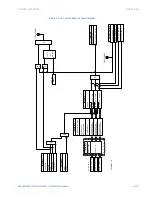

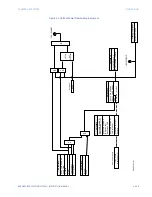

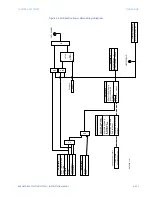

Figure 4-126: Power Factor logic diagram

894170A1.cdr

SETP

OINT

Configurable

Trip Function

Disabled

Trip

Motor S

topped

FLEXL

OGIC OPERAND

SETP

OINT

Block

Off

=

0

AND

S

tar

t Block Delay

SETP

OINT

t

BLK

0

SETP

OINT

Latched Alarm

Alarm Function

Disabled

Alarm

OR

AND

RUN

Trip Lag Level

SETP

OINT

Trip Pickup Delay

SETP

OINTS

Trip Dr

opout Delay

t

PKP

t

RST

Alarm Pickup Delay

SETP

OINTS

Alarm Dr

opout Delay

t

PKP

t

RST

AND

Operate Output

Relay

1

(TRIP

)

LED

: TRIP

LED

: Alarm

AND

AND

OR

LA

TC

H

S

R

RESE

T

Command

PF Trip PKP

FLEXL

OGIC OPERANDS

PF Trip OP

PF Alarm PKP

FLEXL

OGIC OPERANDS

PF Alarm OP

SETP

OINT

Trip Output Relay X

Do Not Operate

, Operate

SETP

OINT

Alarm Output Relay X

Do Not Operate

, Operate

OR

when PF

<

0

&

|P

F| <

Trip Lead Level

OR

Trip Lead Level

V

oltage Inputs

-

delta connected

VA

B

VBC

VC

A

Curr

ent Inputs

Phase A Curr

ent

(I

A

)

Phase B Curr

ent

(I

B

)

Phase C Curr

ent (

IC

)

SETP

OINTS

MINIMUM V

O

LT

A

G

E

:

V

AB

≥

MINIMUM

IA

≥

MINIMUM

VBC

≥

MINIMUM

V

CA

≥

MINIMUM

IB

≥

MINIMUM

IC

≥

MINIMUM

AND

OR

V

oltage Inputs

-

w

ye connected

VA

VB

VC

VA

≥

MINIMUM

VB

≥

MINIMUM

VC

≥

MINIMUM

AND

AND

AND

AND

OR

OR

Power Factor of Thr

ee

Phases

(delta

-connected V

Ts

)

Power Factor of V

alid

Phase

(s

)

(w

ye-

connected V

Ts

)

when PF

>

0

&

|P

F| <

Trip Lag Level

RUN

Alarm Lag Level

SETP

OINT

when PF

<

0

&

|P

F| <

Alarm Lead Level

OR

Alarm Lead Level

when PF

>

0

&

|P

F| <

Alarm Lag Level

MINIMUM CURRENT

:

Summary of Contents for 869

Page 10: ...VIII 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL ...

Page 127: ...CHAPTER 3 INTERFACES SOFTWARE INTERFACE 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL 3 49 ...

Page 129: ...CHAPTER 3 INTERFACES SOFTWARE INTERFACE 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL 3 51 ...

Page 538: ...4 406 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL TESTING CHAPTER 4 SETPOINTS ...

Page 578: ...6 22 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL FLEXELEMENTS CHAPTER 6 METERING ...

Page 592: ...7 14 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL CLEAR RECORDS CHAPTER 7 RECORDS ...