CHAPTER 4: SETPOINTS

MONITORING

869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

4–319

Speed

The 869 is capable of measuring the motor speed. Any of the input contacts can be used to

read the pulses from the input source. The source of the pulses can be an inductive

proximity probe or Hall Effect gear tooth sensor. The probe could be powered from a power

supply with a maximum of 48 VDC. The speed algorithm calculates the number of pulses in

the window length (WL) and converts it into an RPM value. A minimum pulse width of 10%

of a revolution is required to detect a pulse from the pulse source.

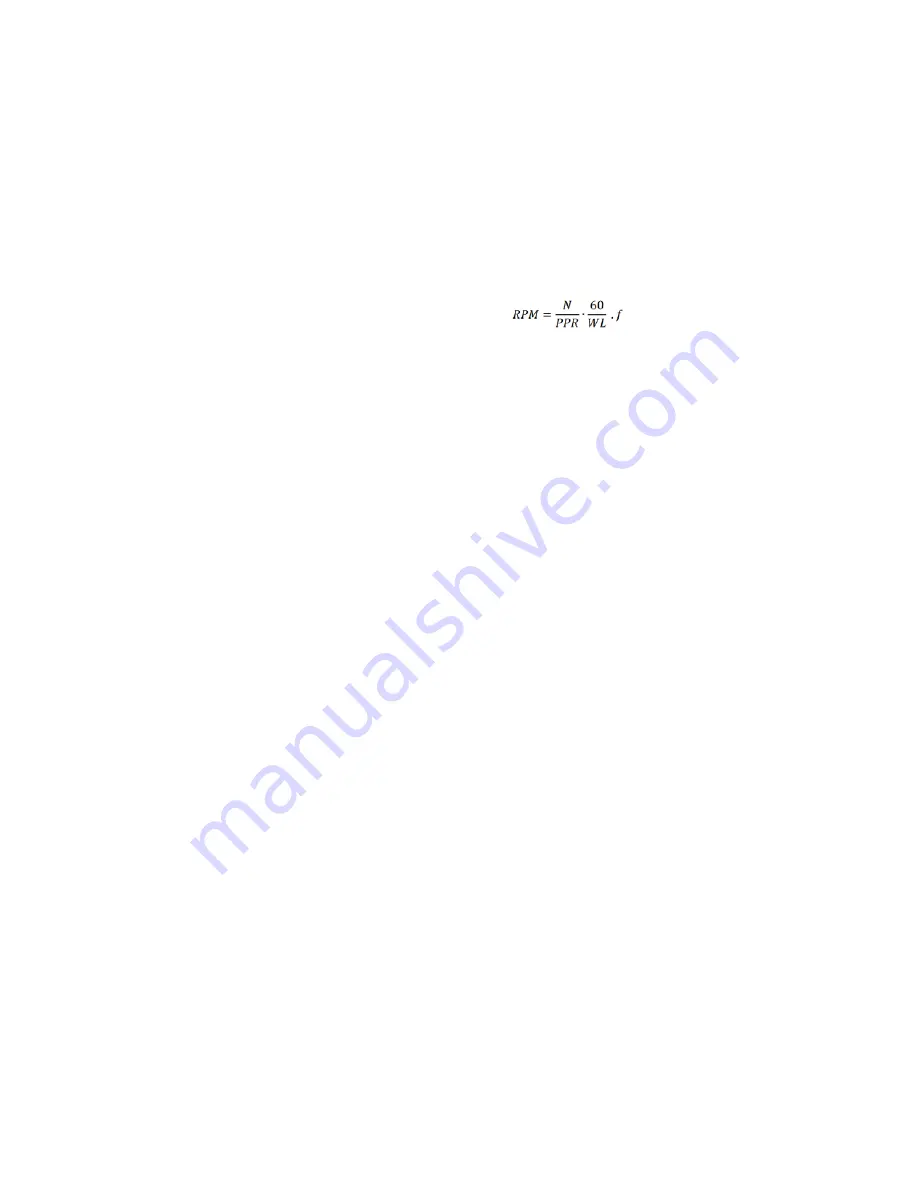

The following equation is used to calculate the speed based on the detection of the

number of pulses ‘N’ during window length WL.

Where:

N – number of pulses during time defined by the setpoint Cal. Window

PPR – pulses per revolution defined by setpoint PULSES PER REV (PPR)

f – system frequency defined under Setpoints\System\Power System

WL – calculated window length in cycles is defined as

WL = (60 x f) / (PPR x 50)

This element has two modes of speed: under speed and over speed which is defined by the

setpoint Direction.

In the under speed mode, a trip and alarm is configured so that the machine must be at a

certain speed within a set period of time from starting. The trip and alarm features are

configured so that the specified speed (Trip Pickup or Alarm Pickup) must be reached in the

specified time (Trip delay or Alarm Delay) otherwise the element operates. Initially, the

time delay begins when the machine starts rotating and resets when the desired speed is

reached. Once the machine is running with the rated speed and then that speed drops

below the set threshold, the time delay restarts and the designated output contact will

operate if the machine fails to reach the set speed in the allotted time.

In the over speed mode, the tachometer trip and alarm features are configured so that if

the specified speed (Trip Pickup or Alarm Pickup) is exceeded for the specified time (Trip

delay or Alarm Delay), the element operates. Initially, the time delay begins when the

machine speed exceeds the pickup value resets when the speed drops below the pickup.

Path

:

Setpoints > Monitoring > Speed

TRIP FUNCTION

Range: Disabled, Trip, Configurable

Default: Disabled

This setting enables the Speed protection Trip functionality.

INPUT

Range: Off, Any Digital Input

Default: Off

Any of the digital input contacts can be used to read the pulses from the input source.

For example, an inductive proximity probe or Hall Effect gear tooth sensor may be used

to sense the key on the motor. The probe can be powered by the +24 V from the input

switch power supply. The NPN transistor output can be sent to one of the digital inputs.

Summary of Contents for 869

Page 10: ...VIII 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL ...

Page 127: ...CHAPTER 3 INTERFACES SOFTWARE INTERFACE 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL 3 49 ...

Page 129: ...CHAPTER 3 INTERFACES SOFTWARE INTERFACE 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL 3 51 ...

Page 538: ...4 406 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL TESTING CHAPTER 4 SETPOINTS ...

Page 578: ...6 22 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL FLEXELEMENTS CHAPTER 6 METERING ...

Page 592: ...7 14 869 MOTOR PROTECTION SYSTEM INSTRUCTION MANUAL CLEAR RECORDS CHAPTER 7 RECORDS ...