P50 Agile P153

8 Monitoring & Control

P153/EN M/B

8-17

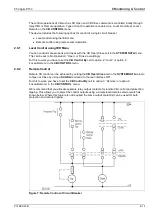

Figure 11: TCS Scheme

When the breaker is closed, supervision current passes through opto input 1 and the trip coil. When

the breaker is open current flows through opto input 2 and the trip coil. No supervision of the trip path

is provided whilst the breaker is open. Any fault in the trip path will only be detected on CB closing,

after the elapse of

TCS timer

available under

CB CONTROL

menu.

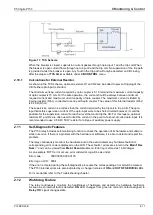

2.10.1

Calculations for External Resistor

As shown in the TCS scheme, optional resistors R1 and R2 can be added to prevent tripping of the

CB if either opto input is shorted.

The minimum sensing current required by opto coupler is 0.18 mA and the maximum current capacity

of opto coupler is 10 mA. For the safe operation, the current should be always between minimum

required current and maximum current capacity of opto coupler. The maximum current is limited by

internal resistor (RInt.) connected in series with opto coupler. The value of this internal resistor (RInt.)

is 82 KΩ (Ohm).

The supervision current is a lot less than the current required by the trip coil to trip a CB. The opto-

input limits this supervision current .If the opto-input were to be short-circuited however; it could be

possible for the supervision current to reach a level that could trip the CB. For this reason, optional

resistors R1 and R2 are often used to limit the current in the event of a short-circuited opto-input. It is

recommended to use

2.5 KΩ / 50

W resistor for all type of auxiliary power supply.

2.11

Self-Diagnostic Features

The P153 relay includes self-monitoring function to check the operation of its hardware and software

while in service. If there is a problem with the hardware or software, it is able to detect and report the

problem.

The relay continuously monitors the hardware and in the event detects any hardware fault/error;

corresponding error code is displayed on the LCD. These faults / errors are stored in the ‘

Main’t Rec

Num

= “and can be viewed from

Maint Record

submenu. Error log is stored as 16 bit integer.

As an example if RTC error occurs, error code/error log will be as under:

Error code :

0000 0000 0000 0100

Error log on LCD: 0004

If the error is cleared during the self-diagnostic procedure the corresponding error bit will be cleared.

The P153 internal errors are also indicated by a change in status of

ON

and

OUT OF SERVICE

LEDs.

For more details refer to the Troubleshooting chapter.

2.12

Watchdog Feature

The relay continuously monitors the healthiness of hardware and detects the hardware fault/error.

As soon as an internal fault is detected,

ON

LED changes from green to red and contact assigned to

‘

Relay OK’

signal changes state.

Summary of Contents for Agile P50 Series

Page 3: ...P50 Agile P153 1 Introduction P153 EN M B 1 1 INTRODUCTION CHAPTER 1...

Page 4: ...1 Introduction P50 Agile P153 1 2 P153 EN M B...

Page 10: ...1 Introduction P50 Agile P153 1 8 P153 EN M B...

Page 11: ...P50 Agile P153 2 Safety Information P153 EN M A 2 1 SAFETY INFORMATION CHAPTER 2...

Page 22: ...Chapter 2 Safety Information P50 Agile P153 2 12 P153 EN M A...

Page 23: ...P50 Agile P153 3 Hardware Design P153 EN M B 3 1 HARDWARE DESIGN CHAPTER 3...

Page 24: ...3 Hardware Design P50 Agile P153 3 2 P153 EN M B...

Page 32: ...3 Hardware Design P50 Agile P153 3 10 P153 EN M B...

Page 33: ...P50 Agile P153 4 Front Panel P153 EN M B 4 1 FRONT PANEL CHAPTER 4...

Page 34: ...4 Front Panel P50 Agile P153 4 2 P153 EN M B...

Page 39: ...P50 Agile P153 5 Configuration P153 EN M B 5 1 CONFIGURATION CHAPTER 5...

Page 40: ...P50 Agile P153 5 Configuration P153 EN M B 5 2...

Page 150: ...P50 Agile P153 5 Configuration P153 EN M B 5 112...

Page 151: ...P50 Agile P153 6 Protection Functions P153 EN M B 6 1 PROTECTION FUNCTIONS CHAPTER 6...

Page 152: ...6 Protection Functions P50 Agile P153 6 2 P153 EN M B...

Page 168: ...7 Protection Parameter Settings P50 Agile P153 7 2 P153 EN M B...

Page 189: ...P50 Agile P153 8 Monitoring Control P153 EN M B 8 1 MONITORING CONTROL CHAPTER 8...

Page 190: ...8 Monitoring Control P50 Agile P153 8 2 P153 EN M B...

Page 207: ...P50 Agile P153 9 SCADA Communications P153 EN M B 9 1 SCADA COMMUNICATIONS CHAPTER 9...

Page 208: ...12 SCADA Communications P50 Agile P153 9 2 P153 EN M B...

Page 220: ...12 SCADA Communications P50 Agile P153 9 14 P153 EN M B...

Page 221: ...P50 Agile P153 10 Installation P153 EN M B 10 1 INSTALLATION CHAPTER 10...

Page 222: ...10 Installation P50 Agile P153 10 2 P153 EN M B...

Page 234: ...13 Commissioning Instructions P50 Agile P153 13 2 P153 EN M B...

Page 242: ...12 Maintenance and Troubleshooting P50 Agile P153 12 2 P153 EN M B...

Page 250: ...12 Maintenance and Troubleshooting P50 Agile P153 12 10 P153 EN M B...

Page 252: ...13 Technical Specifications P50 Agile P153 13 2 P153 EN M B...

Page 263: ...P50 Agile P153 14 Wiring Diagrams P153 EN M B 14 1 WIRING DIAGRAMS CHAPTER 14...

Page 264: ...14 Wiring Diagrams P50 Agile P153 14 2 P153 EN M B...

Page 267: ......