MAINTENANCE

INSPECTION

B E F ORE INSPECTION OR ANY MAINTE

NANCE W ORK IS D ONE, BE SURE T HAT T HE

BREAKER IS IN T HE OPEN P OSITION.

ALL

E LECTRICAL P OWER, B OT H PRIMARY A ND

C ONTROL S OURCES, S HOULD A LS O BE DIS

C ONNECTED.

Periodic inspection of the circuit breaker

is recommended at least once a year.

More

frequent inspections are recommended, if severe

load conditions, dust, moisture, or other un

favorable conditions exist.

If

the breaker remains open or closed for

a long period of time, it is recommended that

arrangements be made to open and close it several

times in succession, preferably under load.

At all times it is important not to permit pencil

lines, paint, oil or other foreign materials to re

m ain on the insulating surfaces of the breaker

as they may cause low resistance between points

of different potential and result in eventual elec

trical breakdown.

Always inspect the breaker after a short

circuit current has been interrupted.

At the time of periodic inspection, the follow

ing checks should be made after the breaker has

been de -energized.

1 . Manuall y operate the breaker several times

checking for obstructions or excessive friction.

2 . Electrically operate the breaker several times

(if breaker has electrical control) to ascertain

whether the electrical attachments are func

tioning properly.

3 . Remove and inspect the arc quencher. Break

age of parts or extensive burning will indicate

ne ed for replac ement.

4.

Check contact condition and wip e

5 . Check latch engagement.

6. Check operation of tripping devices, including

overcurrent trip devices, making sure all

have positive tripping action.

(Discernible

movement in tripping direction beyond point

of tripping. )

(For detailed information o n breaker features

listed, refer to appropriate sections of these

instructions.)

SEPARATION OF FRONT AND BACK FRAMES

Figure 3

Many maintenance operations will either re

quire or be greatly facilitated by separating the

front frame and mechanism of the breaker from

the back frame or base, which consists of the

current carr ying parts of the breaker and their

supporting struc ture.

The p rocedure for this

operation is as follows :

1 . Remove the arc quenchers (see section on

"Arc Quenchers ").

2. Disconnect the two insulated connecting links

(6), between the mechanism and the crossbar

( 10), by removing the tie bolt

(7),

and slipping

the ends of the links off the ends of the should

ered pin, {5) Figure 5 in the mechanism.

3 .

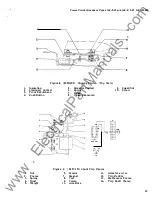

If

the breaker is a drawout type, with secondary

disconnects, Figure 2, remove the secondary

disconnect supporting bracket from the breaker

back frame. Also remove any wiring bundle

retainers that may be attached to the back

frame.

4.

Remove one elastic stop nut from each of

two s tuds (3), which tie the upper ends of the

mechanism frame to the back frame of the

breaker.

5. Remove the two elastic stop nuts {9/1 6 " Hex.)

which fasten the wrap around portion of the

front frame to the back frame. One of these

is located on each side of the breaker, about

2/3 of the distance down from the top edge

of the back frame.

On drawout breakers for AKD Equipment, the

bottom plate must be removed by first remov

ing two #8-3 6 screws located at the front of the

bottom plate and then freeing the plate from the

slots located in the bottom of the back frame.

6 . The two frames are now disconnected. How

ever, care should be exercised in separating

them to avoid dam age to the trip shaft arms

and paddl es.

While the back frame i s held

steady, lift the front frame and mechanism

up and out so that the trip paddles on the

trip shaft clear the trip arms of the overload

trip devices .

Reassembly of the two breaker halves is

accomplished b y following the procedure out

lined in reverse order.

LUBRICATION

In general,. the circuit breaker requires very

little lubrication.

Bearing points and sliding

surfaces should be lubricated very lightly at the

regular inspection periods with a thin film of

extreme temperature, high pressure, light grease,

similar to

G.

E . Spect. No. D50H1 5 or RPM No. 5.

Hardened grease and dirt should be removed from

latch and bearing surfaces by the use of a s afe

cleaning solvent such as kerosene. Latch surfaces

should be left clean and dry and not be lubricated.

5

www

. ElectricalPartManuals

. com