CLOSING SOLENOID

The closing solenoid consists of a magnet,

armature and coil.

This assembly is located

directly beneath the breaker mechanism to which

it is connected by a link which ties the upper end

of the armature

to

the spring carrier of the

mechanism. (See Figure 5.)

When voltage is

to the coil, the

magnetic force

pulls the armature up

into the coil and magnet assembly.

This, in

turn, rotates the spring carrier about its pivot,

extending the mechanism spring and causing its

line of action to move "over center", resulting

in a closing operation.

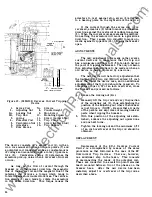

REPLACEMENT

The only replacement operation that might

conceivably be required on this assembly is

that

of

the solenoid

coil.

To replace this, proceed

as follows :

1.

Remove escutcheon by unfastening four flat

head screws in flange.

2.

Remove closing switch. (See "Closing switch ".

)

3.

C ut off or disconnect the coil leads.

4.

Remove four screws which fasten lower s ection

of magnet to upper section.

5.

Allow lower s ection of magnet and coil to

need not be removed from the old bracket. This

can be taken off the breaker simply by removing

the two screws which fasten it to the breaker frame.

If

the breaker is a drawout type, the supporting

bracket of the

"Y"

relay may be temporarily

displaced to provide access to the screws.

Since the expendable parts of the

"X"

contactor

are the contacts and the coil, ease of replacement

of these parts has been designed into the relay.

Methods of procedure are as follows:

Contacts

1.

Remove relay cover.

2.

Remove terminal binding screw of stationary

contact to be replaced.

3.

Lightly pinch with pliers (pointed end) the

split section of the contact which enters the

hole in the compound body of the device and

lift out the stationary contact.

4.

5.

6.

With

the fingers, pull forward on the spring

guide of the movable contact, compressing

the contact spring as far as possible.

With the spring thus held, grip the end of the

contact strip with pointed pliers, turn

it

through

90

degrees on its long axis,

an d

withdraw it.

Replace new contacts by

reversing the pro

cedure.

slide

downwar d until clear of armature.

Coil

6.

Reassemble with new coil by reversing order

of procedure.

" X "

C ONTACTOR

The " X" contactor is a heavy- duty relay which

performs the function of closing the circuit of the

breaker solenoid during electrical operations.

Three of the four sets of contact of the device are

arrange d in series to m inimize the duty require d of

any one contact. As e xplained un der "Operation",

the fourth contact is use d to "seal-in" the

"X"

coil.

The

"X"

contactor is located on the right

beneath the horizontal front frame member. It

is mounte d on three studs which fasten it to a

mounting bracket which is s uspended from the

frame.

Rubber bushings on the mo unting studs

provide anti-vibration and anti-shock protection

for the relay.

The relay contacts and their

terminals are covered by a mol de d piece of

ins ulation which fits over spring clips that hold

the cover in place.

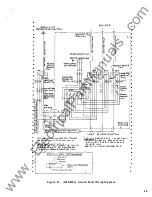

REP LACE MENT

Removal of the complete device is accomp

lishe d by removing the cover, disconnecting the

leads from the terminals, and removing the nuts

from the three mounting studs .

If

the replacement

unit includes the mounting bracket, the relay

16

1.

Remove relay cover.

2.

Turn the two retaining spring clips on the ends

of the device through

90

degrees about their

p ivots.

3.

P ull out the two halves of the body of the devic e

which carry the stationary contacts . When

these are clear of the frame, the armature

and movable contact assembly will move aside ,

e xposing the coil.

4.

Remove the termin al screws of the coil and

p ull it free of its retaining spring clips.

5.

Place new coil on pole piece inside of the

spring clips and fasten terminals to leads.

6.

Just start the replacement of one of the

compound blocks which hold the stationary

contacts into its groove in the frame.

7.

Position the armature and movable contact

assembly to allow the entrance of the second

stationary contact block.

8.

When these parts are all properly aligned,

with the stationary contacts un der the movable

contacts, push them into their g uiding grooves

in the frame

until

they bottom.

•

www

. ElectricalPartManuals

. com