GEI-50299

Power Circuit Breakers Types

AK-2-15

and

AK-2/3-25

TROUBLES HOOTING

ALL E XCESS LUBRICANT S HOULD BE REMOVED

WITH A CLEAN CLOT H

IN

ORDER TO A V OID

ANY ACCUMULATION OF DIRT OR DUST.

At each maintenance period, all s ilver to

s ilver friction points, such as primar ydisconnects,

should be cleaned and g iven a fresh coat of G. E .

Spec. No. D50H4 7 lubr icant.

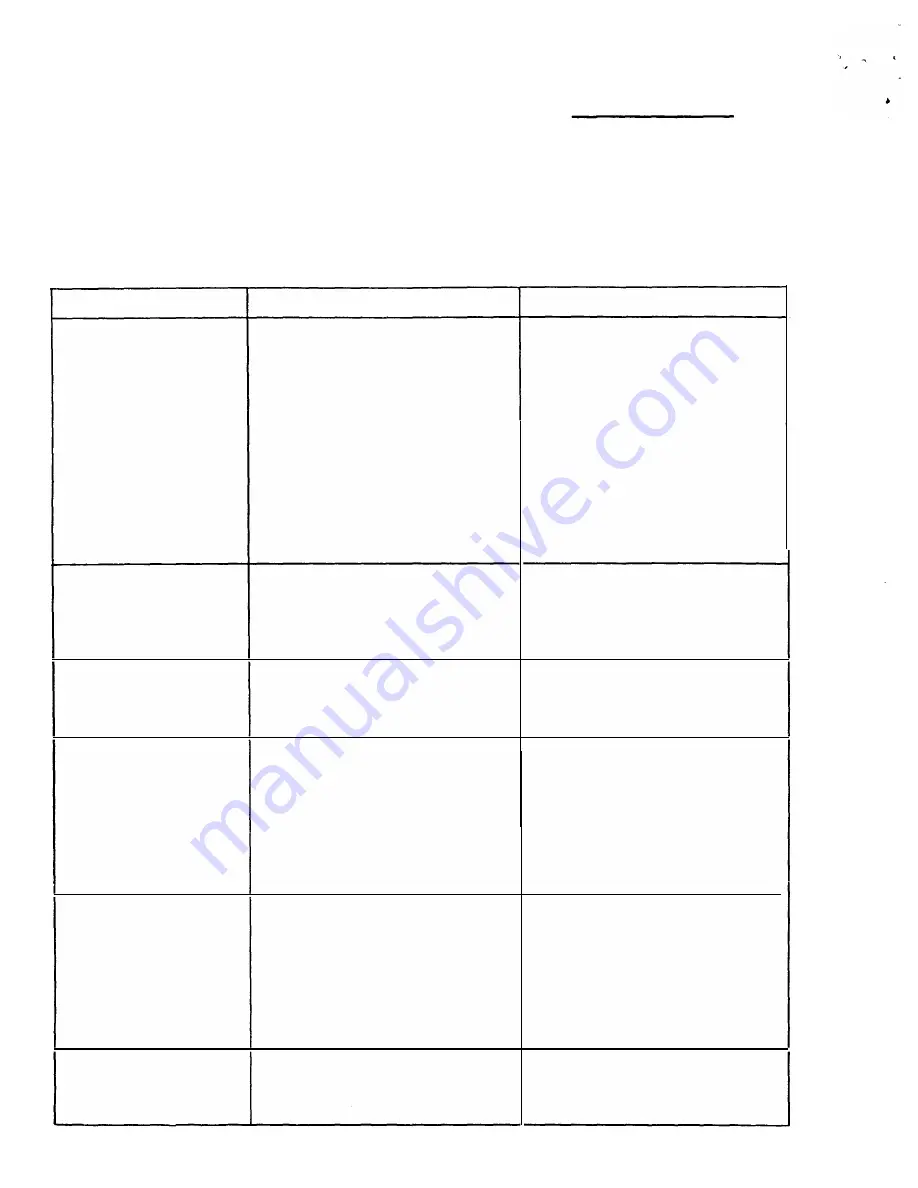

The following table l ists several typ ical s ymp

toms of breaker malfunct ion, together with the ir

causes and remedies.

If, at any tim e, these

s ymptoms are observed, the ir cause should be

determined and the necessar y corrective action

should be taken.

TROUBLE

CAUSE

REMEDY

Overheating

Contacts not aligned

Adjust contacts.

AK-2/3 Breakers

Contacts dirty, greasy or coated with dark

film

Clean contacts

Contacts badly burned or pitted

Replace contacts

Current carrying surfaces dirty

Clean surfaces

of

current carrying parts

Corrosive atmosphere

Relocate or provide adequate enclosure

Insufficient bus or cable capacity

Increase capacity

of bus

or cable

Bolts and nuts at terminal connections

Tighten, but do not exceed elastic limit

of

not tight

bolts or fittings.

Current in excess

of

breaker rating

Check breaker application or modify circuit

by decreasing load

Excessive ambient temperature

Provide adequate ventilation

Failure to trip

Travel of tripping device does not provide

Re-adjust or replace tripping device and

AK-2 Breakers

positive release

of

tripping latch

check mechanism latch adjustment

Worn or damaged trip unit parts

Replace trip unit

Bind in overcurrent trip device

Replace overcurrent trip device

False Tripping

Overcurrent trip device pick up too low

Check application

of

overcurrent trip device

AK-2 Breakers

Overcurrent trip device time setting too short Check application

of

overcurrent trip device

Bind in overcurrent trip device

Replace overcurrent trip device

Failure to Close and Latch

Bin

�

in attachments preventing resetting

Re-align and adjust attachments

AK-2/3 BreaKers

of

late

Latch out

of

adjustment

Adjust latch

Latch return spring too weak or broken

Replace spring

Hardened or gummy lubricant

Clean bearing and latch surfaces

Closing solenoid burned out

Replace solenoid coil

Solenoid control device not functioning

Re-adjust or replace device

properly

False Tripping

Captive Thump screw on Power Sensor

AK-3 Breakers

loose fail-safe circuitry reverts

Tighten thumb screw on desired setting

characteristic

to

minimum setting and

maximum time delay

Tap setting dial on Power Supply incorrectly

Set

dial to

correspond with Power Sensor coil

set

tap

External Ground Sensor Coil improperly

Refer

to

Figure 22, page 29 for polarity and

connections. Check continuity of shield and

connected

conductors connecting the external Ground

Sensor coil.

Failure to Trip

Loose or disconnected power sensor dis-

Tighten or reconnect disconnect plugs

AK-3 Breakers

connect plugs

Loose or broken power sensor coil tap

Tighten or reconnect tap connections

connections

6

www

. ElectricalPartManuals

. com