SECTION 7 -Breaker Maintenance (Cont.)

TRIP PADDLE

ASM

MAINTAIN

MODIFIED

THI

BUFFER

DIMENSION

ASM

FIG. 31 - 2ND

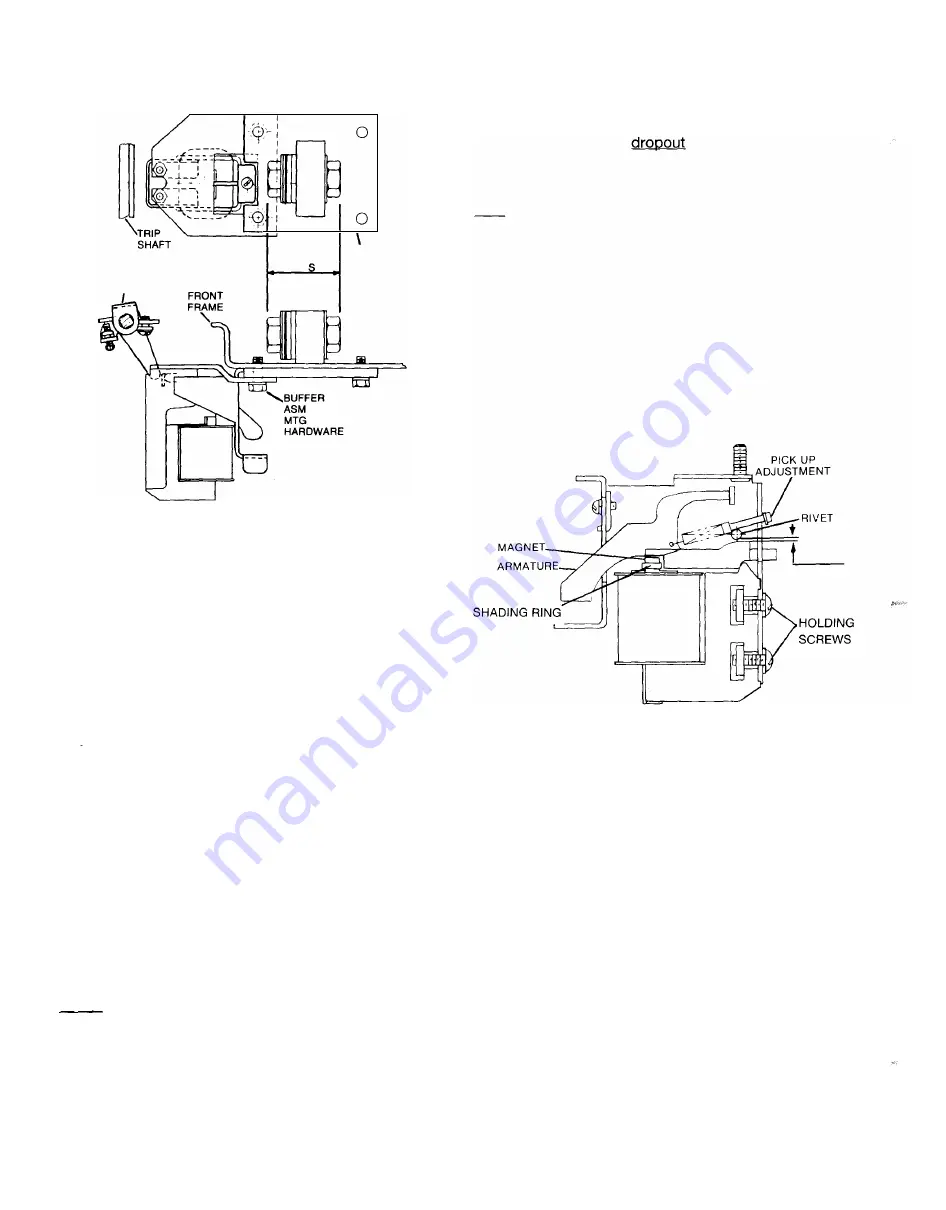

UNDERVOLTAGE DEVICE

7.8.2

OPERATIONAL CHECK

(BREAKER WITH UV DEVICE INSTALLED)

Check the pickup and dropout values at room tempera

ture. See table 2 5 .

Check t h e positive trip ability a s follows: With the

armature closed, close the breaker. Insert a 0.032

±

.005

inch shim (wire gage or flat stock) against the armature

open stop (see Fig. 32D) and release the armature. The

breaker must trip.

7.8.3

ADJUSTMENTS

If the operational checks (7. 8.2) indicate that adjust

ments are necessary, these procedures should be followed:

First

verify trip latch engagement as described in sec

tion 7 . 1 5 , and verify that the trip shaft torque required to

trip a closed b reaker is no g reater than 24 inch-ounces.

Then proceed as follows:

PICKUP VOLTAGE:

The Q.i.Q.!s!,m level is changed by turning the adjustment

screw shown in Fig. 32A. The screw is secured by either

a locking wire or a jam nut inside the frame. Devices with

a jam nut require removal of the device to make this

adjustment. The pickup voltage at room temperature

(approx. 20-24

oq

should be 85% or less of coil rating and

should be measured at the secondary d isconnects with

the coil energized .

Note: On

DC

devices set the gap

between the armature and magnet initially to 0. 030 inch

using the closed gap adjustment screw shown in Fig. 32C

before making pickup adjustments.

Be sure to secure the pickup adjustment screw with the

jam nut or lockwire.

24

DROPOUT VOLTAGE:

On AC devices the

level will fall within the

required limits (30% to 60% of the coil rating) if the pickup

is set properly. On DC d evices, the d ropout level may

need independent adjustment. This is accomplished

after the pickup level has been established per the above

procedure. If required, use the closed gap adjustment

screw shown in Fig. 32C to obtain the d ropout setting. A

gap must remain between the armature and magnet on

DC devices to prevent sealing in u pon loss of voltage.

Secure the adjustment screw with the locknut and apply

RTV to the locknut.

POSITIVE TRI P:

Check positive trip ability per 7.8.2. Adjust the trip

paddle screw if necessary to assure positive trip. With the

undervoltage device closed (picked u p), and the mecha

nism reset, there m ust be clearance between the trip

paddle and the device armature. If clearance adjustment

IS

necessary, re-verify positive trip ability.

FIG. 32A

U N D ERVOL TAGE DEVICE

7.8.4

FACTORY SETTINGS

.00 1 "

. 0 1 0 "

This section covers certain factory settings as an aid to

�

rouble shooting. They are for reference only, and are not

mtended to be field adjusted. They should not be consid

ered criteria for acceptance or rejection.

ARMATURE LOCATING RIVET:

The rivet shown in figu re 32A serves as a locater for the

armature. A clearance of 0.001 to 0.0 1 0 inch should exist

between the rivet and armature as shown in fig. 32A. The

rivet should be able to turn freely.

ARMATU RE OPEN GAP:

The air gap between the armature and the magnet with

�

he d evice de-energized should be approximately 0.250

mches. This is, checked by inserting a 0.201

±

.005 inch

d iameter gage pin between the armature and magnet as

shown in Fig. 328.

www

. ElectricalPartManuals

. com