So long as the actuator remains i n the Reset posi

tion the breaker can be closed and opened normally

'

.

at will. However, when a closed breaker rece1ves a

trip signal from the programmer unit, the actuator is

energized and its solenoid flux opposes the magn�t,

allowing the spring to release the armature; th1s

drives the trip rod against the trip shaft paddle, tripp

ing the breaker.

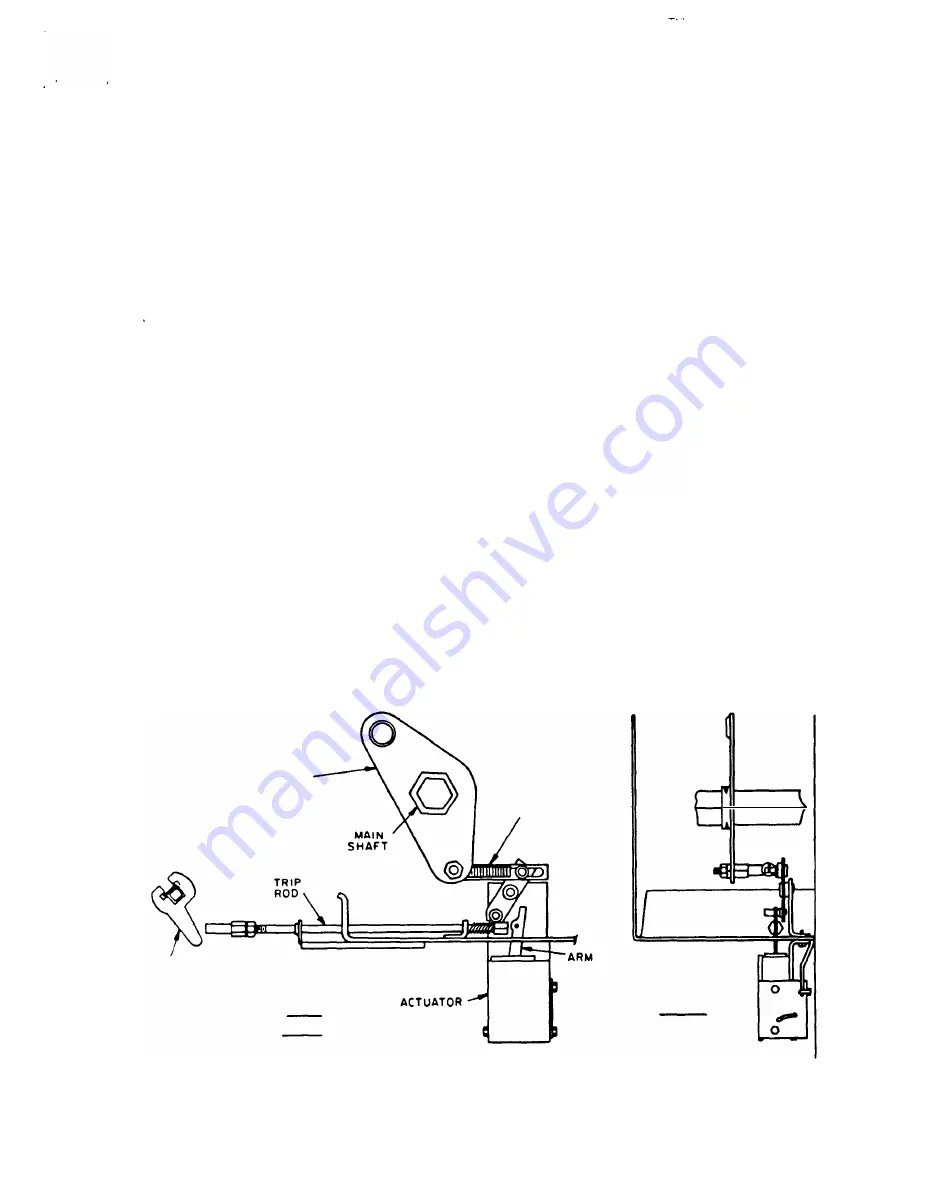

As the breaker opens, the actuator arm-is returned

to its normal (Reset) position via linkage driven by a

crank on the breaker's main shaft. The permanent

m agnet again holds the armature captive in readiness

for the next trip signal.

The trip device requires only one adj ustment - the

trip rod length. As shown fn Fig. 66, the clearance

between the trip rod and the trip shaft paddle is gaged

by a

0.1 25

inch diameter rod. Adjust gap to

0.1 25

inch

±

0.01 5

inch. To adjust, open the breaker and restore

the breaker mechanism to its Reset position. Loosen

the jamb nut, rotate the adjuster end until the proper

gap is attai ned, then retighten the jamb nut to 3

5

±

5

in-lbs.

The actuator is a sealed, factory-set device and re

quires no mai ntenance or field adjustment. In case of

malfunction, the complete actuator unit should be

replaced. When making the electrical connector to

the replacement unit, it is recom mended that the brea

ker harness be cut at some convenient

p

oint and the

new actuator leads solder-sp liced thereto.

The preferred method is to remove the flux shifter

leads from the

A M P

connector using the

A M P

extrac

tion tool, Cat. No.

3051 83

as follows:

T R I P

PADDLE

C RANK

(

BREAKER

)

CLOSED POSITION

S I D E

V I E W

1 .

Remove the flux shifter leads from the harness.

2.

Referri ng to the cabl ing diagrams in Section

1 0.5,

the flux shifter leads are RED ifl point B and BLACK i n

point E.

3. Insert the extractor tool over the female pin.

When the extractor tool bottoms out, depress the

plunger and force the wire/socket assembly out of the

connector.

4. No tool is required to i nsert the wire/socket

assembly i nto the connector. Insert the assembly un

til It snaps i nto place.

5. Verify all sockets are inserted to the same depth.

CAUTION:

IN THE EVENT THAT THE SST TRIP DE

VICE MUST BE RENDERED INOPERA TIVE TO

ALLOW THE BREAKER TO CARRY CURRENT

WITHOUT BENEFIT OF OVERCURRENT PROTEC

TION, THE RECOMMENDED METHOD IS TO

SHORTEN THE TRIP ROD BY TURNING ITS AD

JUSTER END FULL Y CLOCKWISE. THIS PRE

VENTS ACTUATION OF THE TRIP SHAFT PADDLE.

RESET

LINKAGE

FRONT

V I E W

-

FIG. 64 - FLUX SHIFT TRIP DEVICE AND OPERATING LINKAGES

49

www

. ElectricalPartManuals

. com