– 5 –

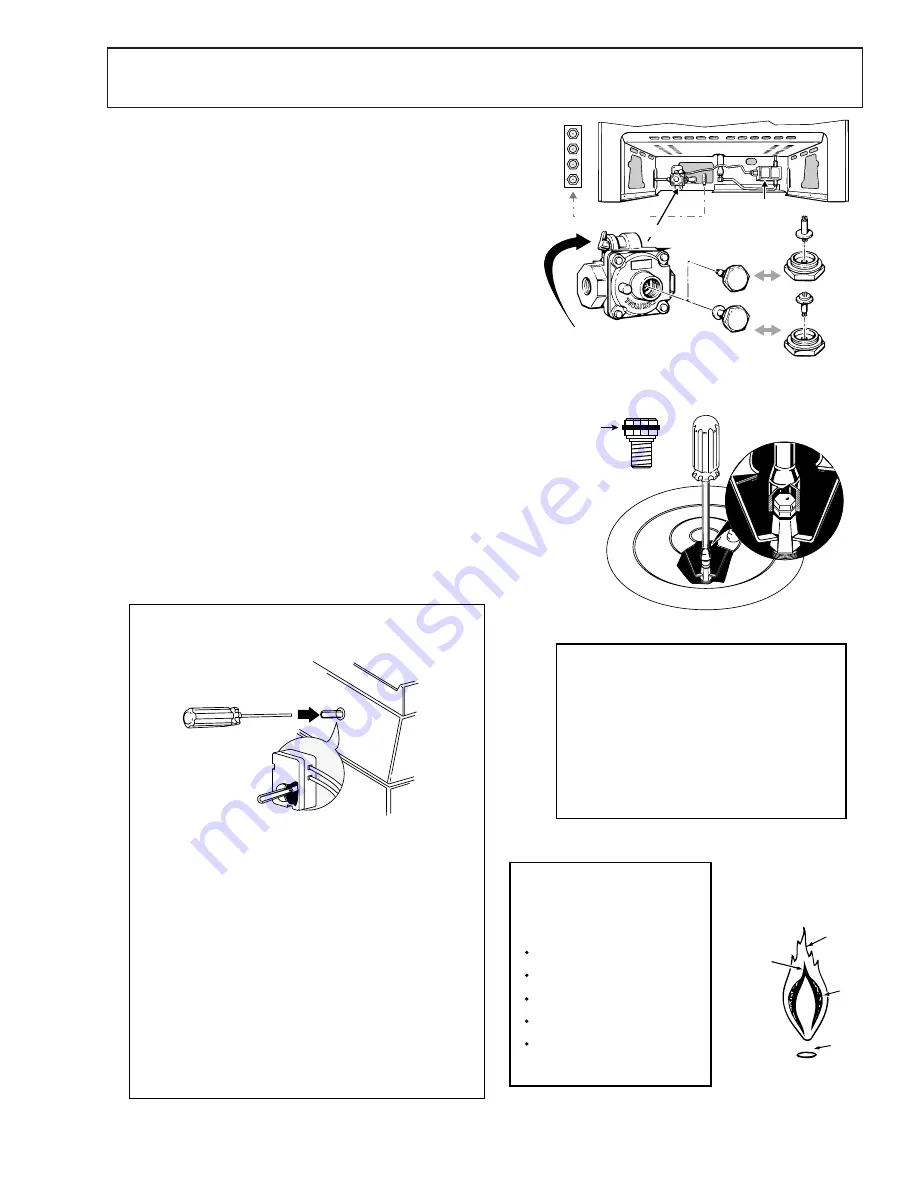

Gas Valve

(Safety Valve)

LP Orifice Spuds

Natural

LP

Pressure Regulator

SHUT OFF LEVER

Oven Only

Lever shown "CLOSED"

Pull lever to "OPEN"

Convert Regulator - Regulator is located in the lower, left

hand rear corner of the range as viewed from the front.

Depending on the model, remove the storage drawer,

broiler drawer or false panel to access the regulator. Some

models with a broiler drawer will have a metal cover over

the regulator that must be removed for conversion and

reinstalled when conversion is complete.

To Convert - Remove the large hex-nut which is located in

the center of the regulator. Remove the plastic pin from

the bottom side of the cap, turn the pin 180 degrees and

snap the pin back into the cap. There are raised letters on

the flat side of the plastic pin, "NAT" and "L.P.". In the "LP"

position the end of the pin marked "NAT" should be

snapped into the bottom of the hex-nut.

Remove surfaced burners and replace all 4 top burner

orifices spuds with the L.P. orifice spuds supplied with the

range (refer to the Technical Data Sheet supplied with the

product for proper L.P. spud location and orifice color

identification).

Using a 1/2" wrench, tighten the orifice hood(s) supplying

gas to the oven burner(s) clockwise until snug.

Open the air shutter on the oven burner(s) to the full open

position and adjust as needed.

Adjust the low flame (simmer) setting on the surface

burners.

2

3

4

5

1

The top burner valves have low flame/simmer

adjustment screws in the center of the control shafts. A

flashlight may be required to locate the screw. A small

thin blade screwdriver (approx. 3/32" blade width) is

needed to engage the screw.

TO ADJUST THE LOW FLAME SETTING - at least two

other burners must be lit. Light the burner being adjusted

and turn the knob to "LOW". Remove the knob and

insert the screwdriver into the shaft of the control valve.

Turn the adjustment screw to obtain the desired flame

size.

TEST FLAME STABILITY - by quickly turning the knob

from "HI" to "LOW". If the flame goes out, increase the

flame size and test again. Also, test flame stability by

quickly opening and closing the oven door. If the flame

is extinguished by the air current created by the door

movement, increase the flame size.

LOW FLAME (SIMMER) ADJUSTMENTS

The top burner orifices can be removed by

removing the burner cap and burner heads.

Using a 7 millimeter (mm) or a 9/32" nut-driver

carefully slide the driver down over the orifice

and rotate counterclockwise to remove.

IMPORTANT NOTE: The orifices have a spring

loaded retaining ring around the hex head to

hold the orifice in the nut driver during

installation and removal. A slight amount of

force is required to push the nut driver down

over the ring.

Retaining

Ring

Yellow Tip

& Soot

Outer

Cone

Flame Lifts

Off Burner

Inner Cone

Pushed Through

Outer Cone

IMPROPER FLAME

Yellow Tips, Soot and/or

Flame Lifting off Burner

TOP BURNER FLAME ADJUSTMENTS

The top burners do not have air shutters

adjustments and use non-adjustable

orifices. If the flame lifts off of the

burner, or if you experience "Yellow Tip"

flames and/or soot in the flames, be sure

to check the following:

Gas pressure: 4" W.C.P. (natural) and

10" W.C.P. (L.P.)

Inspect orifice to be sure it is drilled in

the center and free of debris or burrs.

Be sure the correct size orifice is in

the proper location

Make sure the range was properly

converted if on L.P.

If the cause of sooting can not be

found in the above checks, replace

the orifice with one having a smaller

diameter opening

Conversion to L.P. (Propane) Gas

5.

4.

3.

2.

1.

Summary of Contents for Appliances Profile JGB920

Page 4: ......

Page 5: ......

Page 14: ... 12 Special Features ...

Page 15: ... 13 ...

Page 16: ... 14 Fault Code Memory Display ...

Page 18: ... 16 On Board Diagnostic Tests 1 3 2 ...

Page 19: ... 17 7 4 5 6 ...

Page 20: ... 18 8 ...

Page 21: ... 19 Troubleshooting ...

Page 22: ... 20 Notes ...

Page 26: ......

Page 28: ... 26 Notes ...