– 7 –

Upper Control Panel Access

Remove Control Panel

1. Grasp the light panel cover at the rear, where it is

hinged to the control panel. Lift upward at the rear,

just far enough to insert a small, thin bladed screw-

driver between the end cap and the fluorescent light

cover. Be sure to wrap the blade of the screwdriver

with tape to avoid scarring the plastic shield. Slide

the blade forward toward the front while lifting up the

cover.

2. Remove screws (A) and (B) that secure the endcaps

to the control console. Be careful when removing the

endcap not to break the locating tab at the bottom of

the endcap.

3. Loosen screw C 2 turns. This screw is just long

enough that it will protrude into a slot in the side

frame, causing the panel to bind as you slide it down

and forward. Loosening the screw a couple of turns

will back it off enough that it will no longer protrude

into the side frame slot.

4. Grasp the face panel at the bottom front with one

hand, while gently pushing down on the top of the

control panel with your other hand. Pull control panel

downward to release it from the vent deflector while

at the same time pulling the panel forward from the

bottom.

Remove Capacitive Touchpad

1. Remove 2 screws at each end of the control panel.

2. Carefully separate the control panel from the

touchpad to avoid damaging the seal strips above

and below the touchpad.

NOTE: On the circuit board behind the control panel is a

circuit jumper that may fall off during disassembly. When

reconnecting the jumper, be sure to position it on the left

and center pins. Incorrect assembly of the circuit

jumper will result in ECP failure.

HINGED ON

BACK SIDE

FLIP PANEL UP TO ACCESS

FLOURESCENT LIGHT

LOOSEN

THIS SCREW TO

RAISE CONTROL PANEL

BE SURE TAB IS

IN SLOT WHEN

REINSTALLING

REMOVE 2 SCREWS

TO REMOVE TOUCHPAD

A

B

C

SIDE

FRAME

VENT DEFLECTOR

Pull control panel

down and forward to

release it from the

vent deflector

GEA00170

Circuit

Jumper

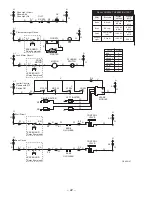

Summary of Contents for Appliances Profile JGB920

Page 4: ......

Page 5: ......

Page 14: ... 12 Special Features ...

Page 15: ... 13 ...

Page 16: ... 14 Fault Code Memory Display ...

Page 18: ... 16 On Board Diagnostic Tests 1 3 2 ...

Page 19: ... 17 7 4 5 6 ...

Page 20: ... 18 8 ...

Page 21: ... 19 Troubleshooting ...

Page 22: ... 20 Notes ...

Page 26: ......

Page 28: ... 26 Notes ...