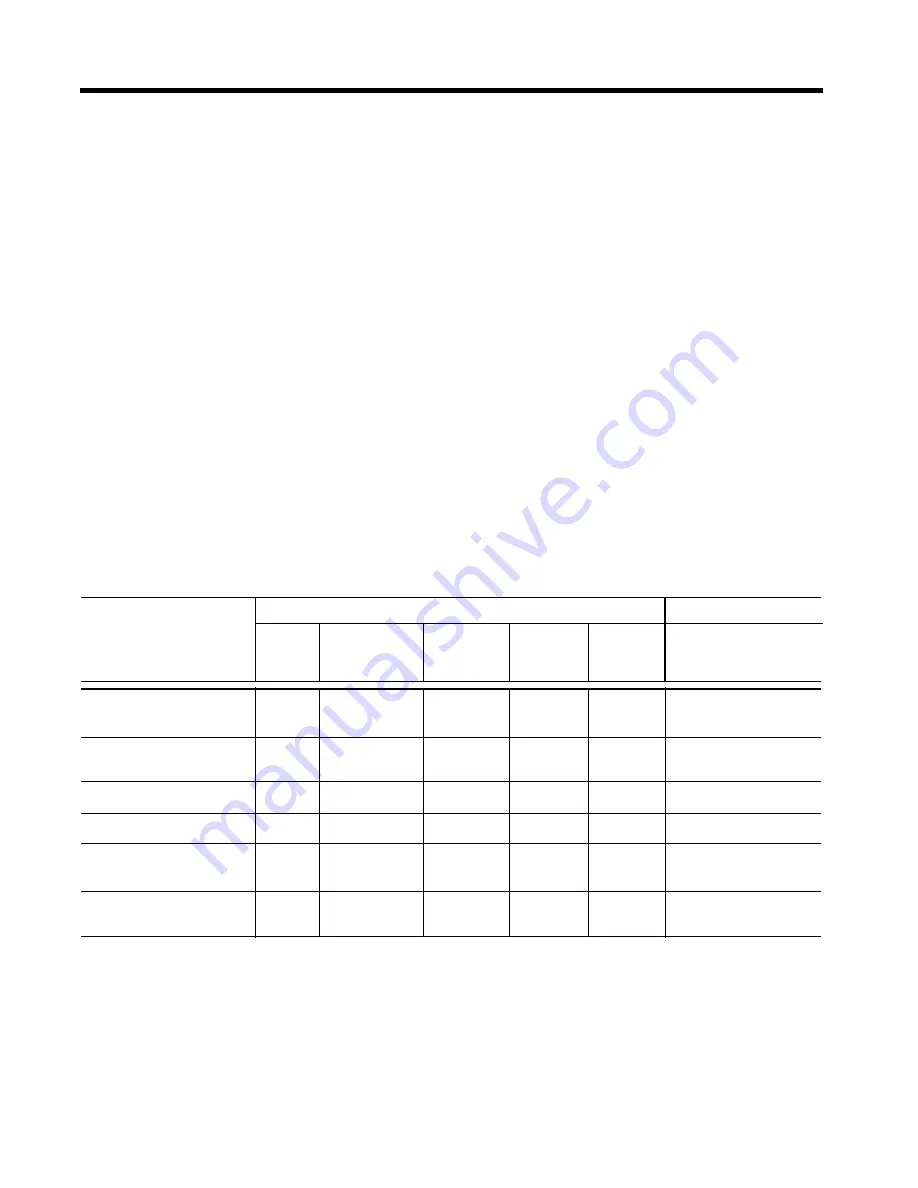

1-1. Comparison of starting systems

There are numerous applications where soft starting and limited

current peak are needed and thereby making direct starting of

squirrel-cage motors impossible. Traditionally in such cases other

types of starting with reduced stator voltage have been resorted to. The

best-known are star-delta starters, autotransformer starters, stator

resistance starters or using part winding motors.

Any reduced starting voltage imposes a current limitation, and as a

consequence the starting torque is also reduced, but there will always

be peaks during the change from one point or state to another which

can damage the machine being driven. In order to analyse the

performances offered by each of these different types of starters, the

following table shows the special characteristics of each of them,

comparing with the ASTAT system.

Note that in general all reduced voltage starts produce a reduction in

torque in squared proportion to the current in the phases of the motor

(not on the line) and the latter in turn is reduced in linear proportion to

the voltage. From this it can be deduced that any start with reduced

voltage reduces the torque in squared proportion to the voltage per

motor phase. From this point of view soft starting produces, just like any

other reduced voltage start, a reduction in starting torque, according

% of direct start

100%

30 - 40 or 64%

58 - 70%

65%

33%

Depending on adjust,

current (in the line)

max. 90%

% of direct start torque

100%

30 - 40 or 64%

33 - 49%

48%

33%

Depending on adjust,

max. 90%

Starting steps (1)

1

4, 3 or 2

3 or 2

2

2

Continuous, no steps

Connections to motor

3

3

3

6

6

3

Line overload

5 In

1,5 - 2,1 or 3,2 In

3 - 3,5 In

3,25 In

1,65 In

Depending on adjust,

(approx.)

max. 4-7 In

Change or

NO

NO

NO

NO

YES

NO

starting pause

(1) "Steps" mean sharp changes of speed during the time from rest until rated speed is reached.

to the adjusted parameters. The advantage, of course, is the ease with

which this ramp can be controlled to produce a soft start in accordance

with the actual requirement of the machine.

From the comparison table it can be seen that the maximum starting

torque attainable using the soft system is 90% of that which direct

starting tends to. Bearing in mind that the direct starting torque varies

between 1.5 and 2.4 times rated torque, it can be deduced that with the

soft starter, starting torques which are somewhat higher than rated are

obtained.

This area includes the starting of pumps, fans, conveyor belts, etc.,

where a torque in the region of 60% of rated is usually sufficient for

correct starting.

As a general rule it can be guaranteed that soft starter will allow starting

of drives which are currently used in conventional starting systems,

with the advantages outlined, and above all the facility to adjust the

current peaks and torque at the machine, faced with the impossibility

or difficulty of varying the steps in conventional systems.

1. Generalities

1-1

CONVENTIONAL STARTERS

SOFT STARTER

Direct

Autotransfo

Stator

Part

resistance

winding

Star-delta

motor