ASTAT XL Service Manual

Troubleshooting

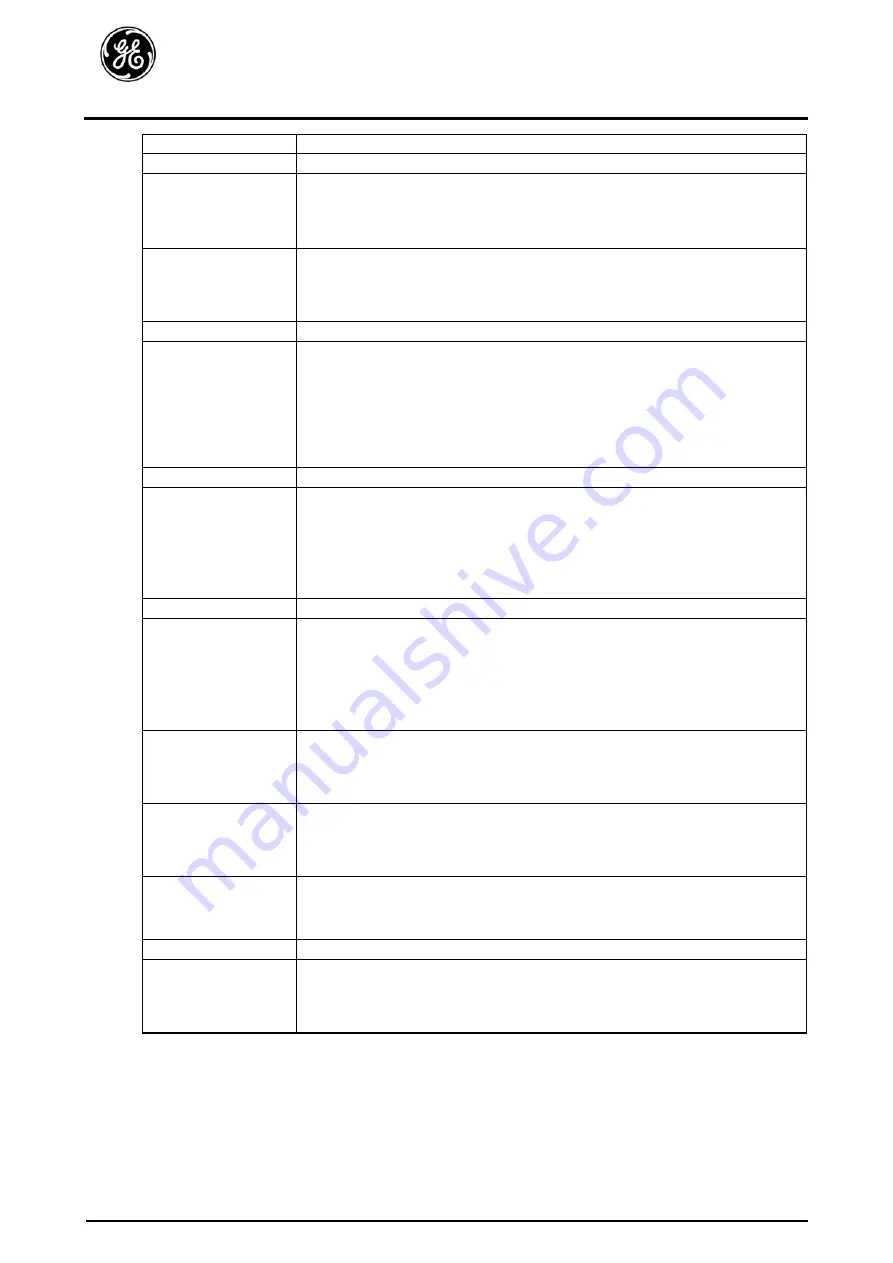

Display

Possible cause/Suggested solution

No Flow

This is a name selected for a programmable input. See Input A trip.

Parameter out of

range

•

A parameter value is outside the valid range.

The starter will load the default value for all affected parameters. Press

RESET

to go to the first invalid parameter and adjust the setting.

Related parameters: None

Phase sequence

The phase sequence on the soft starter's input terminals (L1, L2, L3) is not valid.

Check the phase sequence on L1, L2, L3 and ensure the setting in parameter

4B is suitable for the installation.

Related parameters: 4B

PLC

This is a name selected for a programmable input. See Input A trip.

Power loss

The starter is not receiving mains supply on one or more phases when a Start

Command is given.

Check that the main contactor closes when a start command is given, and

remains closed until the end of a soft stop. Check the fuses. If testing the soft

starter with a small motor, it must draw at least 2% of its minimum FLC setting

on each phase.

Related parameters: None

Pump Fault

This is a name selected for a programmable input. See Input A trip.

Starter

communication

(between module and

soft starter)

•

There is a problem with the connection between the soft starter and the

optional communications module. Remove and reinstall the module. If

the problem persists, contact your local distributor.

•

There is an internal communications error within the soft starter. Contact

your local distributor.

Related parameters: 16I

Starter Disable

This is a name selected for a programmable input. See Input A trip.

Thermistor circuit

Check that a PT100 (RTD) is not connected to 64, 65.

The thermistor input has been enabled and:

•

The resistance at the input has fallen below 20

Ω

(the cold resistance of

most thermistors will be over this value) or

•

A short circuit has occurred. Check and resolve this condition.

Related parameters: None

Time-overcurrent

The ASTAT XL is internally bypassed and has drawn high current during

running. (The 10A protection curve trip has been reached or the motor current

has risen to 600% of the motor FLC setting.)

Related parameters: None

Undercurrent

The motor has experienced a sharp drop in current, caused by loss of load.

Causes can include broken components (shafts, belts or couplings), or a pump

running dry.

Related parameters: 4C, 5C, 16C

Unsupported option

(function not

available in inside

delta)

The selected function is not available (eg jog is not supported in inside delta

configuration).

Related parameters: None

Vibration Alarm

This is a name selected for a programmable input. See Input A trip.

VZC Fail Px

Where 'X' is 1, 2 or 3.

Internal fault (PCB fault). Contact your local supplier for advice.

This trip is not adjustable.

Related parameters: None

10

DET-813