4.1

Measurement method

The instrument uses a probe which is excited by an

AC signal (60 kHz “L” or 500 kHz “H”) from the main

unit. This AC signal uses the material to be measured

as a coupling medium to a detector coil also in the

probe. From the phase and amplitude of the detected

signal the instrument calculates the conductivity of the

coupling medium.

Only conductivity of non-magnetic metallic materi-

als can be measured using this system. Conductivity

changes considerably with temperature so the probe is

fi tted with a thermistor. It’s temperature is monitored in

order to display a mathematically adjusted conductivity

reading relative to 20 °C. The instrument will indicate

the necessity for a Probe Reset after a temperature

change of +/–3 °C. The set routine should be carried

out just before a measurement if absolute accuracy is

required.

A certain amount of surface unevenness and nonmetallic

coatings up to 0.020" (0.5 mm) are allowed for in the

measurement system (0.010" (0.25 mm) only with the

8 mm probe). When the probe has exceeded this “lift-

off” distance, PROBE OFF METAL will be displayed.

4.2

Display

The display is a back lit LCD, the back light can be set

ON or OFF. When in Measurement Mode the display

will indicate the numerical value of the material being

measured in % IACS (I) or MegaSiemens/meter (S)

depending on the units selected. PROBE OFF METAL

is displayed if the probe is in air and not in close prox-

imity to a measurable material.

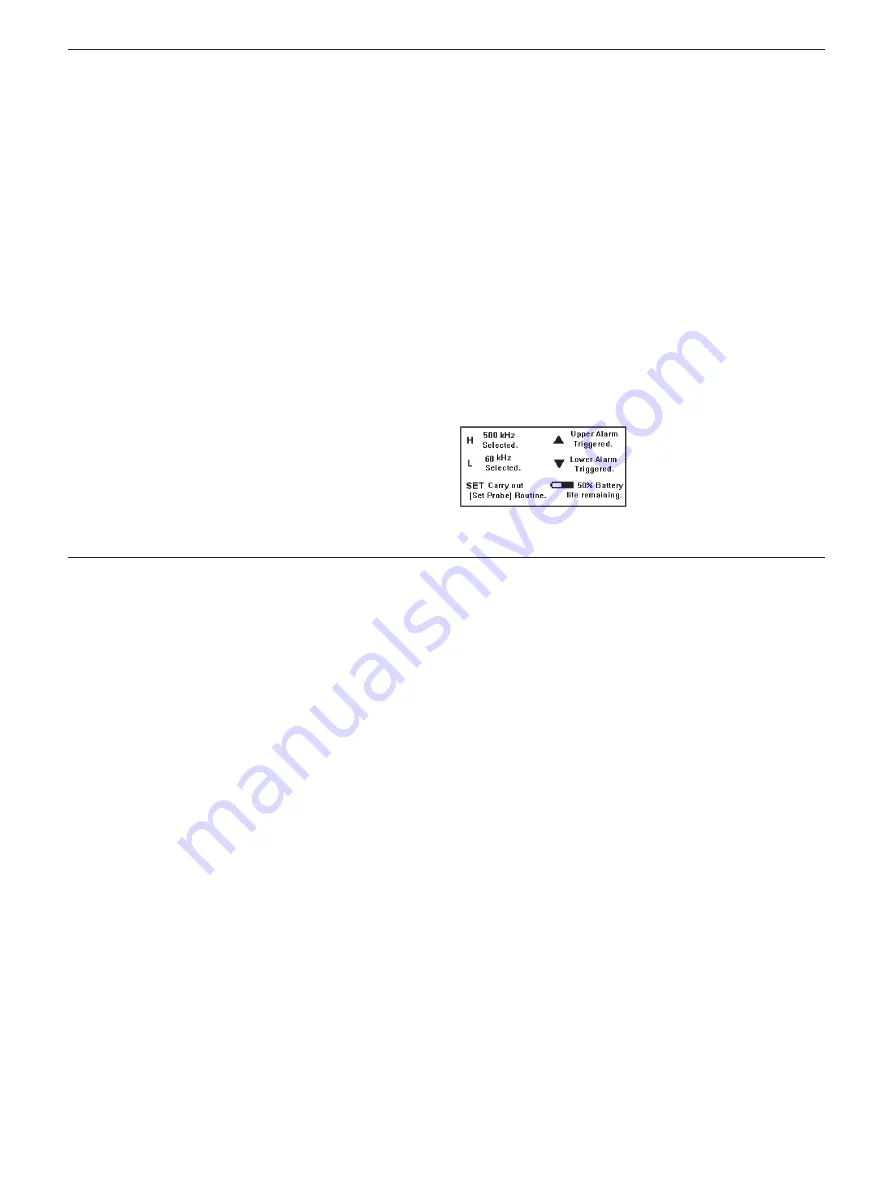

Other display modes can be selected which are used

for setting up operational parameters, or logging fi les

(see chapter 5). In these Modes the display will high-

light the parameter being set and its current status. In

the measurement mode Alarm States are indicated

by icons at the bottom of the display. The frequency,

probe code selected, measurement units and state of

charge of the battery are also shown at the bottom of

the display.

Measurement method

Basic functions

4 - 2

Issue 04, 06/2007

AutoSigma 3000

Summary of Contents for AutoSigma 3000 DL

Page 1: ...AutoSigma 3000 Technical Reference and Operation Manual Ident No 071 002 022 47DH01 105 952...

Page 6: ...0 6 Issue 04 06 2007 AutoSigma 3000...

Page 7: ...Introduction 1 AutoSigma 3000 Issue 04 06 2007 1 1...

Page 12: ...1 6 Issue 04 06 2007 AutoSigma 3000...

Page 13: ...Standard package and accessories 2 AutoSigma 3000 Issue 04 06 2007 2 1...

Page 16: ...2 4 Issue 04 06 2007 AutoSigma 3000...

Page 17: ...Preparation for operation 3 AutoSigma 3000 Issue 04 06 2007 3 1...

Page 27: ...Basic functions 4 AutoSigma 3000 Issue 04 06 2007 4 1...

Page 31: ...Operation 5 AutoSigma 3000 Issue 04 06 2007 5 1...

Page 47: ...External data handling devices 6 AutoSigma 3000 Issue 04 06 2007 6 1...

Page 52: ...6 6 Issue 04 06 2007 AutoSigma 3000...

Page 53: ...Specifications 7 AutoSigma 3000 Issue 04 06 2007 7 1...

Page 57: ...Maintenance and care 8 AutoSigma 3000 Issue 04 06 2007 8 1...

Page 59: ...Appendix 9 AutoSigma 3000 Issue 04 06 2007 9 1...

Page 62: ...9 4 Issue 04 06 2007 AutoSigma 3000...

Page 63: ...Index 10 AutoSigma 3000 Issue 04 06 2007 10 1...