© 2019 Baker Hughes, a GE company, LLC. All rights reserved.

76 |

=

BHGE

GE Oil & Gas

ES-761 Rev H

Page 4 of 13

Copyright 2018 as an unpublished trade secret. This document and all information herein is the property of Dresser LLC. It

is confidential and must not be made public or copied and is subject to return upon demand.

General Requirements

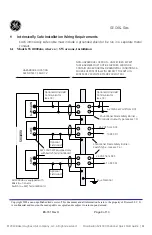

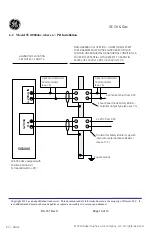

Installation and maintenance must be performed only by qualified personnel. Area Classification,

Protection Type, Temperature Class, Gas Group, and Ingress protection must conform to the data

indicated on the label.

Wiring and conduit must conform to all local and national codes governing the installation. Wiring

must be rated for at least 5ºC above the highest expected ambient temperature

. (ATTENTION – LE

CABLAGE D'ALIMENTATION DOIT ETRE HOMOLOGUE POUR UNE TEMPERATURE SUPERIEURE D’AU

MOINS 5°C A LA TEMPERATURE AMBIANTE MAXIMALE)

Approved wire seals against ingress of water are required and the NPT fittings must be sealed with

tape or thread sealant to meet the highest level of ingress protection.

Where the protection type depends on wiring glands, the glands must be certified for the type of

protection required.

The metal housing is a die-cast alloy which is predominately aluminum.

“X” Marking on label - Since the SVi1000 enclosure contains greater than 10% aluminum; care must

be taken during installation to avoid impacts or friction that could create an ignition source.

"X" Marking on label - Potential Electrostatic Charge Hazard – For safe operation use only wet cloth

when cleaning or wiping device, and only when local conditions around the device are free of

potentially explosive atmospheres. Do not use dry cloth. Do not use solvent.

Before powering the SVi1000:

o

Verify that the cover screws are tightened. This is important to maintain the ingress

protection level.

o

If the installation is intrinsically safe, check that the proper barriers are installed and the

field wiring meets local and national codes for an IS installation. Never install a device

which was previously installed without an intrinsically safe barrier in an intrinsically safe

system.

o

If the pneumatic system is powered by a combustible gas then the installation must be

treated as Zone 0 or DIV I.

! WARNING!

Failure to adhere to the requirements

listed in this document may cause loss

of life and property.

Summary of Contents for BAKER HUGHES Masoneilan SVi 1000

Page 1: ...Masoneilan SVi 1000 Positioner Quick Start Guide Rev L BHGE Data Classification Public...

Page 8: ...This page intentionally left blank...

Page 18: ...This page intentionally left blank...

Page 38: ...This page intentionally left blank...

Page 56: ...This page intentionally left blank...

Page 86: ...This page intentionally left blank...

Page 87: ......