© 2019 Baker Hughes, a GE company, LLC. All rights reserved.

Masoneilan SVi1000 Positioner Quick Start Guide

=

|

83

GE Oil & Gas

ES-761 Rev H

Page 11 of 13

Copyright 2018 as an unpublished trade secret. This document and all information herein is the property of Dresser LLC. It

is confidential and must not be made public or copied and is subject to return upon demand.

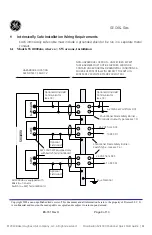

Notes for Intrinsically Safe Installation

7.1

Hazardous Location

Refer to the device label for the description of the environment in which the device may be

installed.

7.2

Field Wiring

Intrinsically Safe wiring must be made with grounded shielded cable or installed in grounded

metal conduit.

(CHAQUE CABLE A SECURITE INTRINSEQUE DOIT INCLURE UN BLINDAGE MIS

A LA TERRE OU DOIT FONCTIONNER DANS UN CONDUIT EN METAL SEPARE)

The electrical

circuit in the hazardous area must be capable of withstanding an A.C. test voltage of 500 volts

R.M.S. to earth or frame of the apparatus for 1 minute. Installation must be in accordance

with GE guidelines. The installation including the barrier earthing requirements must comply

with the installation requirements of the country of use.

Factory Mutual requirements (USA): ANSI/ISA RP12.6 (Installation of Intrinsically Safe Systems

for Hazardous (Classified) Locations) and the National Electrical Code, ANSI/NFPA 70. Division

2 installations must be installed per the National Electrical Code, ANSI/NFPA 70.

CSA requirements (Canada): Canadian Electrical Code Part 1. Division 2 installations must be

installed per the Canadian Electrical Code Division 2 Wiring Methods.

ATEX requirements (EU): Intrinsically safe installations must be installed per EN60079-10 and

EN60079-14 as they apply to the specific category.

7.3

SVi1000 (+) and (-) 4 to 20mA Input Terminals

These terminals power the SVi1000 and are equipped on the Basic, Switch and Position

Retransmit Terminal boards.

Entity Parameters:

Vmax= 30 Vdc

Imax=125 mA

Pmax = 900 mW

Ci = 6.5 nF

Li = 1 uH

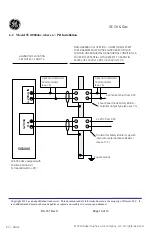

7.4

SVi1000 (+) and (-) SW Output Terminals

There are two independent isolated solid state switch contact outputs on the SVi1000. They

are labeled SW#1 and SW#2. The switches are polarity sensitive (conventional current flows

into the plus terminal). These terminals are equipped only on the Switch Terminal board.

Entity parameters are:

Vmax= 30 Vdc

Summary of Contents for BAKER HUGHES Masoneilan SVi 1000

Page 1: ...Masoneilan SVi 1000 Positioner Quick Start Guide Rev L BHGE Data Classification Public...

Page 8: ...This page intentionally left blank...

Page 18: ...This page intentionally left blank...

Page 38: ...This page intentionally left blank...

Page 56: ...This page intentionally left blank...

Page 86: ...This page intentionally left blank...

Page 87: ......