Masoneilan SVI FF Instruction Manual

=

|

19

© 2019 Baker Hughes, a GE company, LLC. All rights reserved.

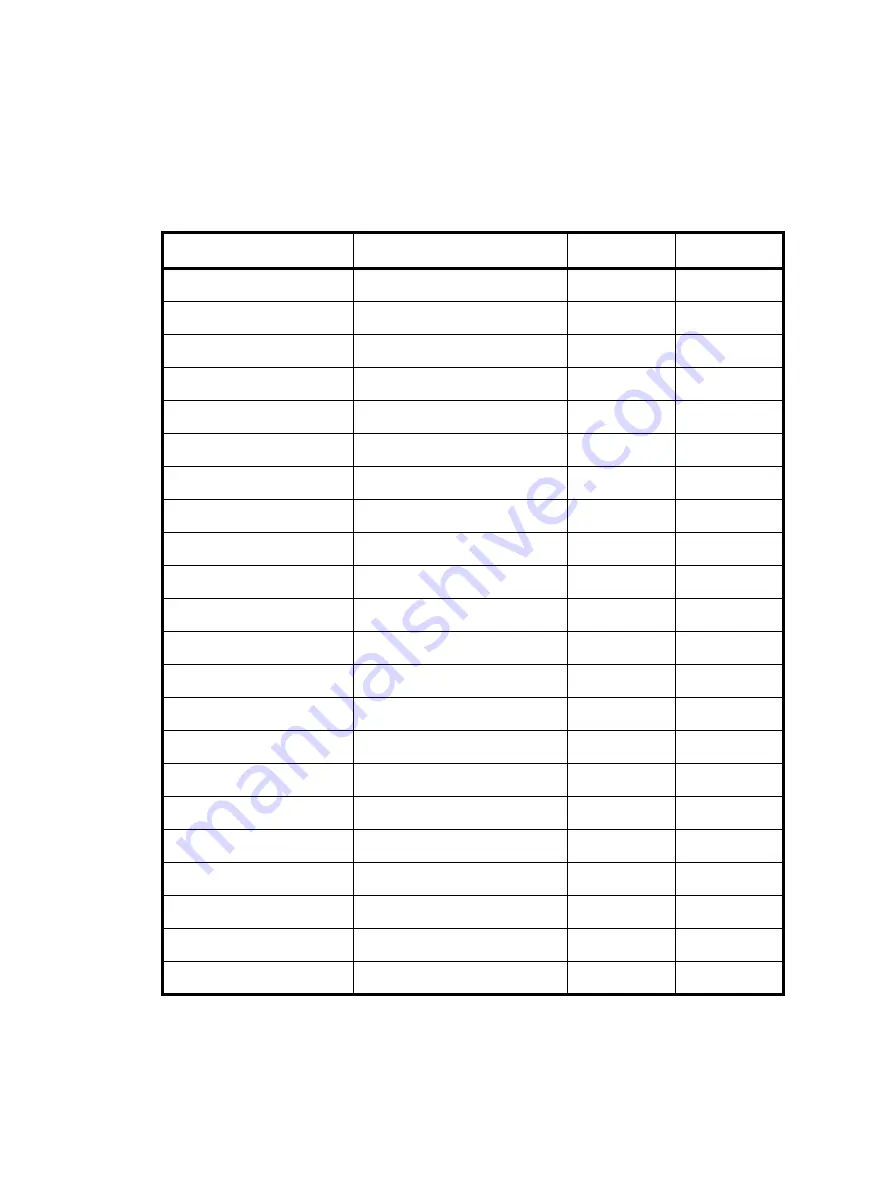

Diagnostic Versions

There are two versions – Standard and Advanced. Table 1 illustrates the capabilities of each

version.

Table 1 Advanced versus Standard SVI FF Diagnostic Versions

Feature

Sub-feature

Advanced

Standard

Device States

Positioner State

X

X

Positioner Alert Log

X

X

Trend and Position Setup

X

-

Device State

X

X

Configuration

Control Configuration

X

X

Extended RB Configuration

X

-

Extended TB Configuration

X

-

Alerts

X

X

LCD Display

X

X

Calibration

Find Stops

X

X

Auto Tune

X

X

Quick Wizard

X

-

Full Wizard

X

-

Diagnostics

Step Test

X

-

Ramp Test

X

-

Signature Test

X

-

Histograms

X

-

Trends

X

-

Identification

X

X

Security

X

-

X

X

Write Notes

X

X

Summary of Contents for Baker Hughes Masoneilan SVI FF

Page 12: ...This page intentionally left blank ...

Page 72: ...This page intentionally left blank ...

Page 82: ...This page intentionally left blank ...

Page 94: ...This page intentionally left blank ...

Page 108: ...This page intentionally left blank ...

Page 198: ...This page intentionally left blank ...

Page 206: ...This page intentionally left blank ...

Page 224: ...This page intentionally left blank ...

Page 228: ...This page intentionally left blank ...

Page 230: ...This page intentionally left blank ...

Page 250: ...This page intentionally left blank ...

Page 262: ...This page intentionally left blank ...

Page 263: ......