7 | GE Oil & Gas

© 2014 General Electric Company. All rights reserved.

3� Remove the positioner from the bracket� The tubing and

fittings on each side of the positioner must be taken off and

installed in the opposite corner from their original position

(see piping schematic provided by GE), then reattach to

the positioner� This will allow the positioner to maintain the

actuator failure mode when the positioner is turned upside

down�

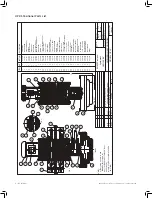

4� Move the bracket assembly, tube assembly, and cover plate

to the positions shown on the desired drawing�

5� Install the positioner in the opposite direction of its original

position (upside down if it was right side up, right side up if it

was upside down)�

6� Using parts from the factory kit, assemble the spring and sur-

rounding hardware according to the drawing of the desired

configuration� (Note: All original parts may not be used when

converting from close on increasing to open on increasing�)

7� The entire bracket assembly or the outer angle may need

to be turned upside down to accommodate the new spring

height�

8� Reconnect the supply, instrument, and output lines according

to piping schematic supplied�

NOTE: The flow direction must be maintained through the

positioner bodies when re-piping� (i�e�, the flow [supply or

exhaust] moves from P1 to P2 and P3 to P4)�

Table 4. Extension Rods for Positioners to Close on

Increasing Signal

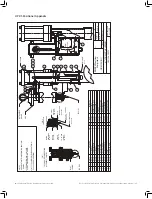

Conversion to Split Range

Converting a standard positioner to a split range positioner (pneu-

matic input other than 3-15 psi or 6-30 psi), requires ordering the

proper conversion kit from the factory� This kit will include a bias

spring and bias spring cartridge� If required, it will also contain a

new range spring and mounting spacers�

1� For close on increasing positioner: Remove the cap on the top

of the positioner along with the spring inside it�

For open on increasing positioner: Remove the mounting

bracket holding the cap on the bottom of the positioner� Then

remove this cap along with the spring inside it�

2� Replace the cap and spring with the larger bias spring

cartridge and bias spring found in the kit� Make sure the bias

adjustment screw in the bias spring cartridge is snug against

the bias spring and the spring is centered before tightening

the spring cartridge�

3� For open on increasing positioner: Remove the washer and

jam nut from the adjusting screw in the bias spring cartridge�

Reattach the mounting bracket upside down from its original

position�

4� Slide the thread spacer (brass bushing) over the adjusting

screw and tighten the washer and jam nut against the thread

spacer�

5� If a range spring was sent with the kit, remove the existing

range spring and replace it with the new one�

6� Adjust the unit per the Adjustment Procedures�

Stroke

With Transmitter

Without Transmitter

4”

25-1402

25-8001

6”

25-8136

25-1093

8”

25-1402

25-1423

NOTE: Refer to Table 1 and Table 2 for bias and range spring part

numbers

Table 5. Split Range Conversion Kits

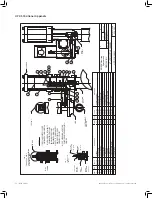

Maintenance and Inspection

As with all precision equipment, it is necessary to periodically test

the positioner to help ensure top performance� We recommend

the following procedure once a year�

1� Shut off supply pressure and bleed down at positioner� Note

the settings of the variable orifices and remove them from

the orifice assembly� Clean them thoroughly and reinstall

using new o-rings, while being sure to install each orifice in

the same hole from which it was removed (the orifice and

block have matching numbers for this purpose)� Reset orifices

to original settings� Turn on supply pressure�

2� Apply a midrange signal to the positioner� Allow the control

valve to become stationary at about 50 percent of the range�

Close the cylinder block valves or move the MCV-3 handle

to the manual position� The positioner is now isolated from

the cylinder� Apply a ± 1/4 psig signal change� Observe the

response in the output gauges� The output pressure should

develop differential pressure equal to 20 percent of the power

gas pressure� If the output pressure does not show immedi-

ate response, the positioner may have too much deadband�

Reduce the deadband by turning the drum in the direction

of decreasing numbers� If the pressures do not respond in

the correct direction when reversing the instrument signal

change, the unit has internal friction� Disassemble the unit

and replace all rubber goods�

3� Check the integrity of the balance valve seats by increasing

the deadband by one full number� When the cylinder top and

bottom gauges are equal to the power gas, the exhaust port

should not exhibit any bleed gas� If either of these tests fail,

then the positioner is not properly adjusted or the unit needs

to be reassembled with new rubber goods�

4� Soap test around all diaphragm interfaces, orifice

assemblies, and vents� If any leaks are found around the

diaphragms, refer to the assembly instructions for replace-

ment of all internal rubber parts�

5� Observe the operation of the gauges� If any gauges are

defective, replace them�

6� Check range and bias� If necessary, readjust per Adjustment

Procedures� Should problems arise or more information is

required, call toll free

(800) 323-8844

for assistance�

Stroke

Close on

Increasing

Open on

Increasing

Reference

Drawings

4 inch

25-6014

25-1464

Proportional:

35-0513

35-0313/A

35-0511

35-0511/A

6 inch

25-6014

25-1465

Proportional:

35-0522

35-0529

8 inch

26-6014

25-1466

Tailrod:

Summary of Contents for Becker HPP-5

Page 18: ... ...