14 mm Proximity Transducer System 7200 Series Installation Manual

12

3. MAINTENANCE

3.1 INTRODUCTION

This section contains calibration and troubleshooting procedures. The recommended maintenance

equipment is given in Table 3-1. If the recommended equipment is not available, equivalent

instruments can be used. Any maintenance performed by the user, other than that which is specified

herein, may void the warranty.

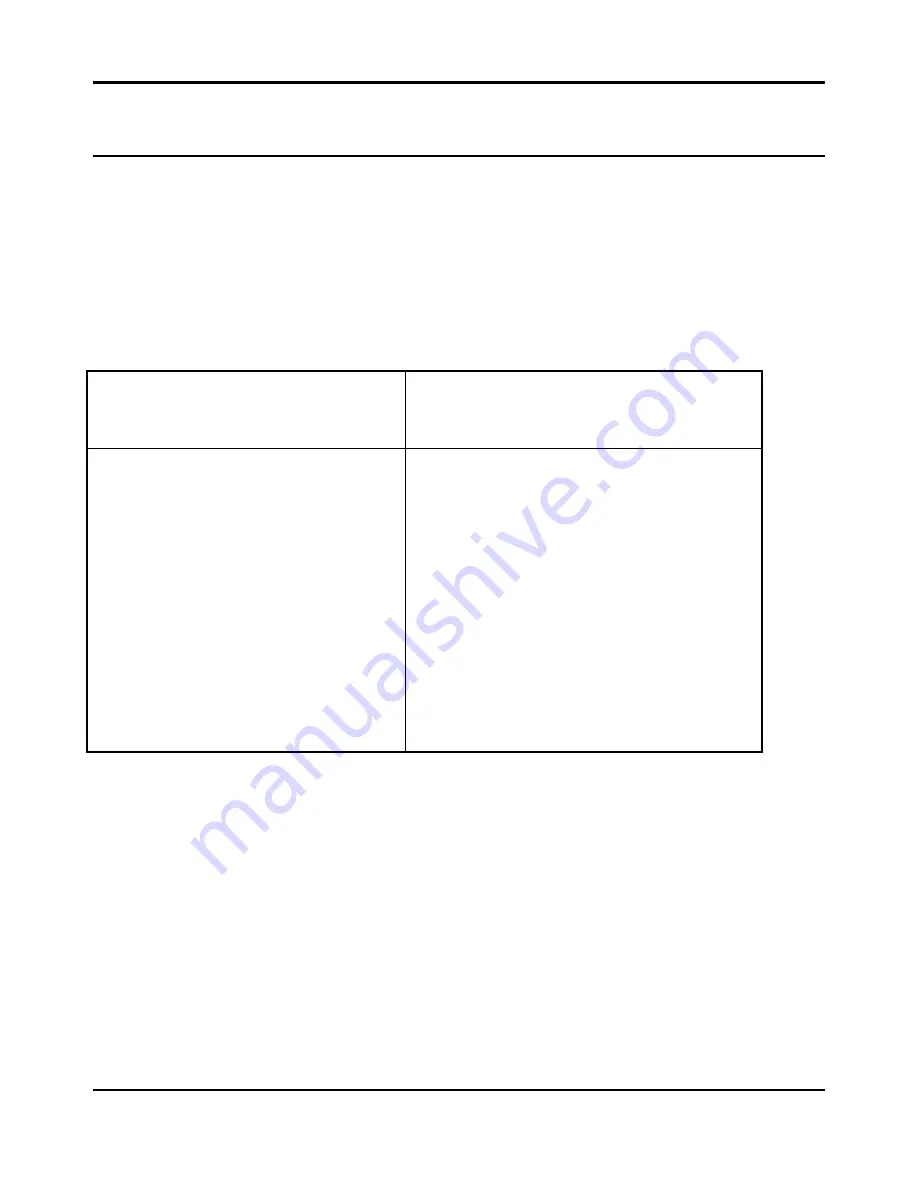

Table 3-1. Recommended Maintenance Equipment

MAINTENANCE EQUIPMENT

RECOMMENDED EQUIPMENT

Digital Multimeter

Test and Calibration Kit

Variable Resistor

Soldering Iron

Power Supply

Hewlett-Packard Model 3465 A/B

Bently Nevada Corporation Model TK3-2E or

TK3-2G

0 to 10k ohms

Weller Model SP23

Hewlett-Packard Model 6215A

3.2 CALIBRATION CHECK

Successful completion of the following procedure assures proper transducer calibration.

a. Connect test equipment as shown in Figure 3-1.

b. Adjust the spindle micrometer on the TK3 test and calibration kit until it indicates 20 mils (0.51

mm).

c. Insert the probe into the TK3 probe holder. Adjust the probe in the holder until the digital

multimeter indicates -2.00 ±0.01 Vdc and tighten the probe in the fixture. Do not contact the

probe tip.

Summary of Contents for Bently Nevada 7200 Series

Page 22: ...APPENDIX A 17 Figure A 1 14 mm Probe Ordering Information ...

Page 24: ...APPENDIX B 19 Figure A 3 14mm Extension Cable Ordering Information ...

Page 34: ...APPENDIX C 29 6 APPENDIX C SCALE FACTORS AND SENSITIVITY CURVES ...

Page 36: ...APPENDIX C 31 Figure C 2 Probe and One Foot Cable at Temperature ...

Page 38: ...APPENDIX C 33 Figure C 4 9 Metres Cable at Temperature ...

Page 42: ...APPENDIX C 37 Figure C 8 Effects of Flat Surface Side Clearance ...