5.4

Column packing

Introduction

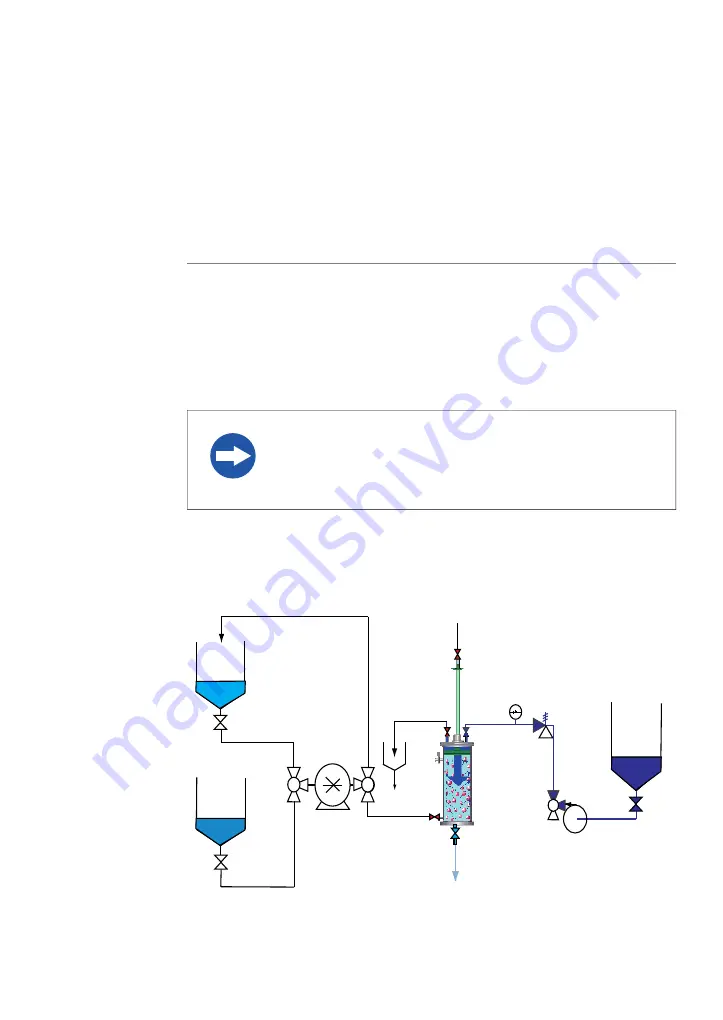

This section describes how to pack media slurry in the column after the column and

hydraulic chamber have been primed.

Packing BioProcess LPLC and

MPLC columns with media slurry

It is recommended that column filling is performed immediately prior to the

column packing step. This will avoid the settlement of media, which may

negatively affect column performance.

Tip:

NOTICE

Make sure the hydraulic chamber has been primed before begin-

ning to pack the media.

For more information about priming the hydraulic chamber see Section 5.2

Priming the column, on page 52.

Note:

To pack a column with media slurry, follow the steps described below:

MPT

C

B

D

A

BSV

HI

HO

MPB

LPLC and MPLC Columns Operating Instructions 28-9638-66 AC

57

5 Operation

5.4 Column packing