5358651-1EN

Rev. 18

© 2021

General Electric Company

All Rights Reserved

For USA, OEC Brivo Prime/OEC Brivo Essential/OEC Brivo Plus are respectively described as

Brivo OEC 715/Brivo OEC 785/Brivo OEC 865 in the manual.

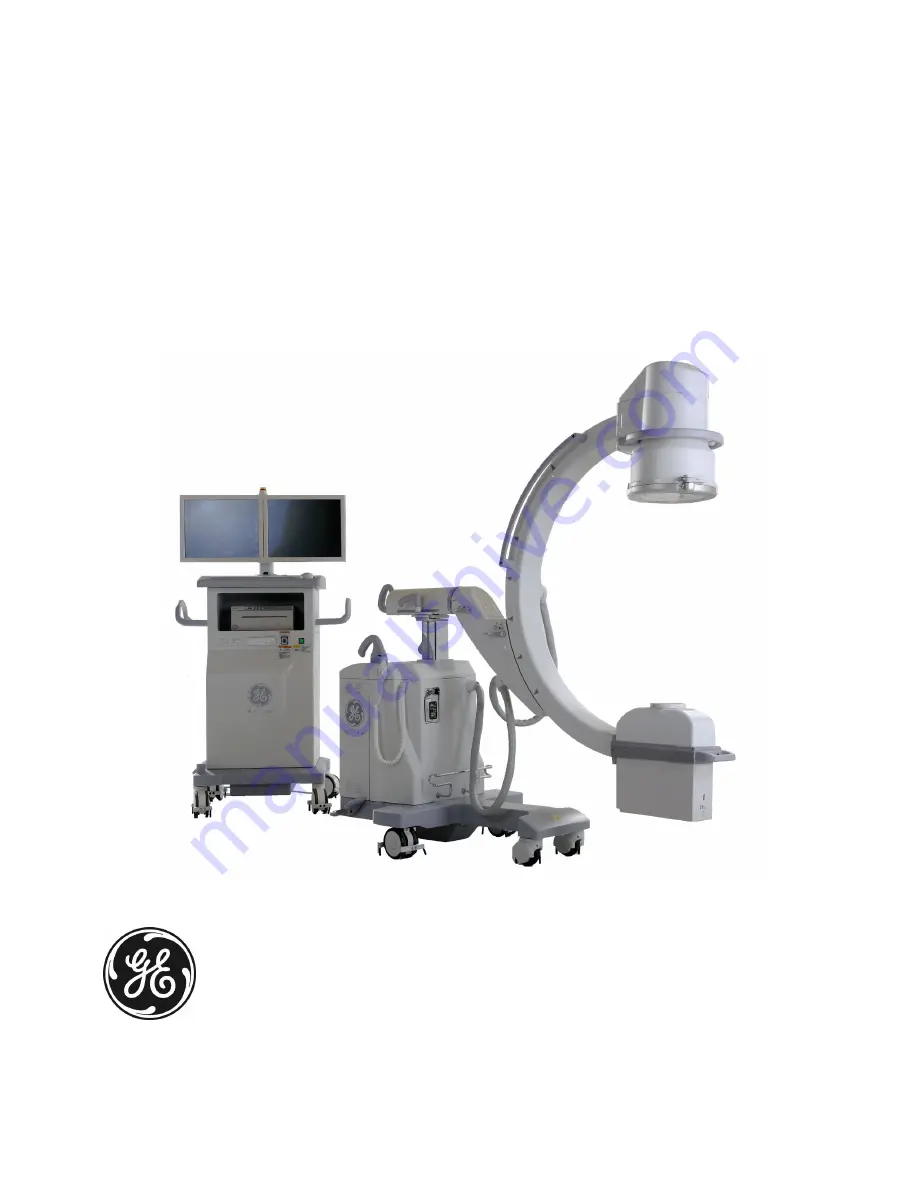

GE Healthcare

Mobile C-arm X-ray Product

Service Manual

Brivo OEC 715/Brivo OEC 785/Brivo OEC 865

Summary of Contents for Brivo OEC 715

Page 2: ......

Page 19: ...Chapter1 Introduction and Safety...

Page 41: ...Introduction and Safety 23 46 54 20 18 26...

Page 55: ...Chapter2 System Overview...

Page 137: ...Chapter3 Installation...

Page 212: ...Chapter4 Calibration...

Page 275: ...Brivo OEC 715 785 865 Mobile C Arm X Ray Product Service Manual 4 64...

Page 284: ...Chapter5 Software...

Page 326: ...Software 5 43 2 Click on install to continue 3 Click Next to continue...

Page 335: ...Chapter6 Troubleshooting...

Page 408: ...Chapter7 Replacement...

Page 418: ...Replacement 7 11 166...

Page 488: ...Chapter8 Periodic Maintenance...

Page 502: ...Periodic Maintenance 8 15...

Page 505: ...Chapter9 Technical Reference...

Page 521: ...Technical Reference 9 17 Vertical configuration 1 5m Vertical configuration 1m...

Page 526: ...11 Appendix System Schematics...