CB Watch 3 User Manual

v6.3 - May 2019

Page 71 of 100

Pneumatic/hydraulic Pressure

Pump operation time

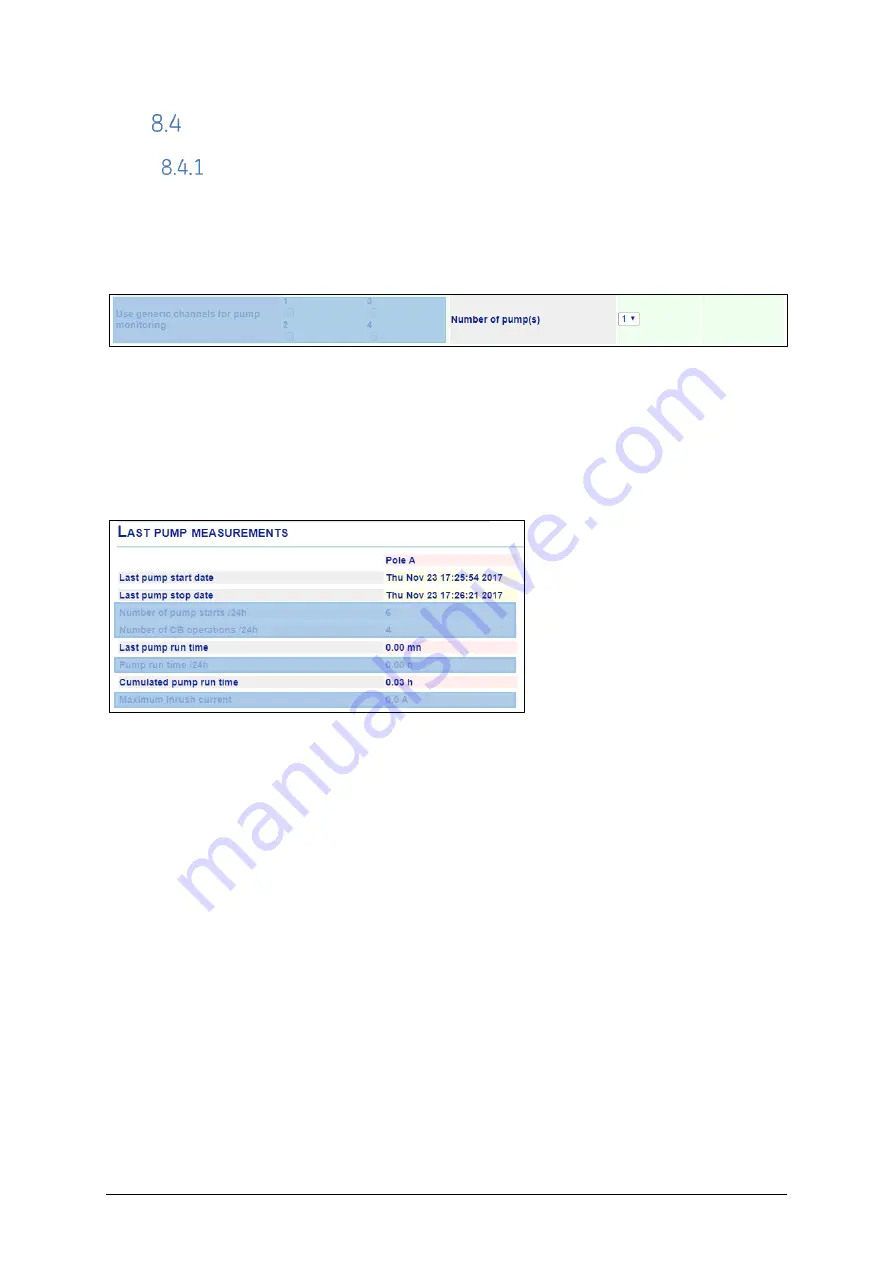

There is usually only one large AC powered compressor/pump to generate the

pneumatic or hydraulic pressure, but the number of motors/pumps can be configured to

either 1 or 3 using the drop-down selector:

HMI: Measurement / Settings / Pump

Figure 114

–

Number of pumps setup

This compressor motor is controlled by a pressure sensor, but by connecting a relay in

parallel to the motor AC supply, we can generate motor on/off signals to acquire the

date/time at which these contacts are activated. We can therefore timestamp when the

compressor pump operates and measure the duration of its operation.

HMI: Measurements / Pump

Figure 115

–

Pump run time

The pump run time is measured for comparison purposes and to spot if the compressor

is needing more time to restore the desired pressure, a possible indication of pump

problem. But the results can be affected if the CB is operated at the same time as the

compressor is trying to restore pressure.

The cumulated pump run time is also displayed so that maintenance of the pump(s) can

be performed when the prescribed number of run time hours has been reached.

Because the pump motor only starts whenever the pressure in the storage tank falls

below a certain level and this depends on the number and types of operations previously

performed, it is difficult to predict when the pump will operate. What is key is that the

pump should not operate if no CB operations were performed, as the only reason for the

pressure to drop and require the pump to operate would be a leak in the system.

Therefore, resetting every day at midnight, we also report in the HMI:

-

The number of pump operations in the last 24 hours

-

The number of CB operations in the last 24 hours

-

The total pump run time in the last 24 hours