– 43 –

3

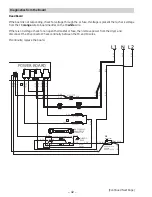

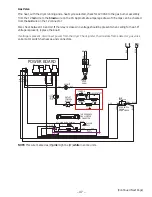

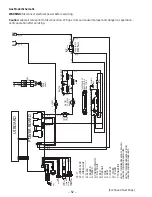

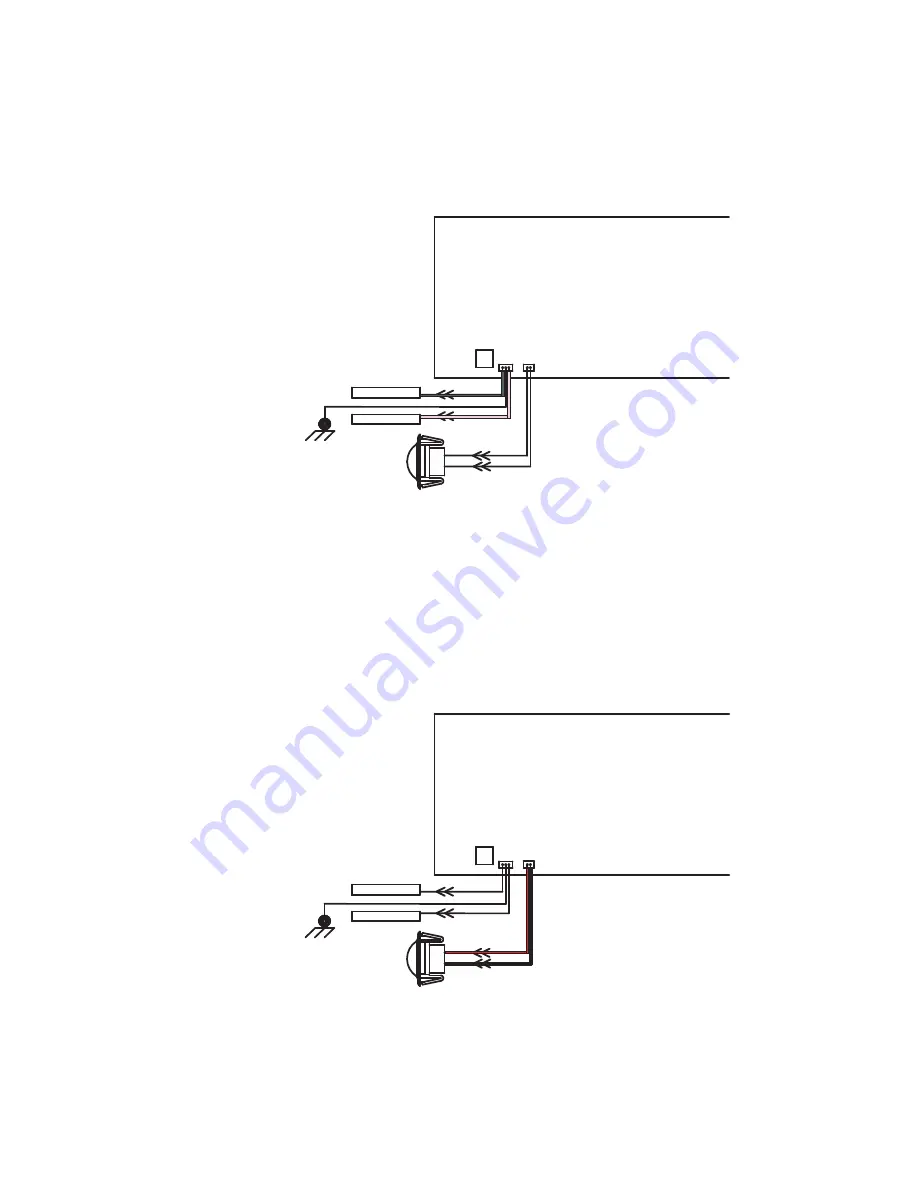

POWER BOARD

J11

J25

1

R-20

B-20

UPPER ROD

LOWER ROD

S-20

P-20

GY-20

CHASSIS

BASE

Moisture Sensor Rods

Check from the the J25 connector on the board and look for approximately 5 VDC. Lay a wet cloth across the

rods in the drum. You should see the voltage drop.

If voltage does not drop, disconnect power from the dryer. Disconnect the J25 connector from the board.

With the wet cloth still across the rods, check the continuity across the pink and gray wires. If no continuity,

visually check harness and connectors for damage. If there is continuity, replace the board.

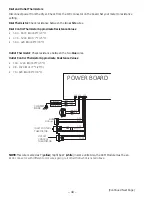

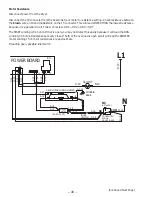

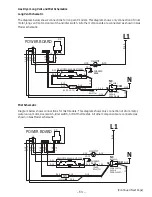

Drum Light

Check from the J11 connector on the board. Look for approximately 3.8 VDC.

If there is voltage, but no light, disconnect the power from the dryer. Disconnect the J11 connector from the

board. Set your meter to DIODE setting. With your BLACK LEAD on the red wire, and your RED LEAD on the

black wire, you should read approximately 0.727 if good. If you reverse your meter leads, RED LEAD on the

red wire, you will not get a reading.

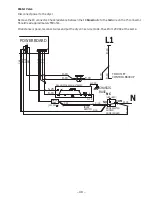

3

POWER BOARD

J11

J25

1

R-20

B-20

UPPER ROD

LOWER ROD

S-20

P-20

GY-20

CHASSIS

BASE

(Continued Next Page)