5-4

D30 Line Distance Protection System

GE Multilin

5.1 OVERVIEW

5 SETTINGS

5

5.1.2 INTRODUCTION TO ELEMENTS

In the design of UR relays, the term

element

is used to describe a feature that is based around a comparator. The compar-

ator is provided with an input (or set of inputs) that is tested against a programmed setting (or group of settings) to deter-

mine if the input is within the defined range that will set the output to logic 1, also referred to as

setting the flag

. A single

comparator may make multiple tests and provide multiple outputs; for example, the time overcurrent comparator sets a

pickup flag when the current input is above the setting and sets an operate flag when the input current has been at a level

above the pickup setting for the time specified by the time-current curve settings. All comparators use analog actual values

as the input.

An exception to this rule is digital elements, which use logic states as inputs.

Elements are arranged into two classes,

grouped

and

control

. Each element classed as a grouped element is provided with

six alternate sets of settings, in setting groups numbered 1 through 6. The performance of a grouped element is defined by

the setting group that is active at a given time. The performance of a control element is independent of the selected active

setting group.

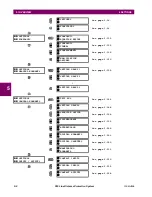

The main characteristics of an element are shown on the element logic diagram. This includes the inputs, settings, fixed

logic, and the output operands generated (abbreviations used on scheme logic diagrams are defined in Appendix F).

Some settings are specified in per-unit (pu) calculated quantities:

pu quantity

= (actual quantity) / (base quantity)

Where the current source is from a single CT, the

base quantity

is the nominal secondary or primary current of the CT. Use

the secondary current base to convert per-unit current settings to/from a secondary current value, and use the primary cur-

rent base to convert to/from a primary current value.

Where the current source is the sum of two or more CTs with different nominal primary current, the primary base quantity is

the largest nominal primary current. For example, if CT1 = 300 / 5 A and CT2 = 100 / 1 A, then in order to sum these, CT2

is scaled to the CT1 ratio. In this case, the base quantity is 300 A primary, 5 A secondary for CT1, and 300/(100/1) = 3 A

secondary for CT2.

For voltage elements the primary base quantity is the nominal phase-to-phase primary voltage of the protected system pro-

vided that the VT ratio setting is set to the nominal ratio of the VTs and the secondary voltage setting is set to the phase-to-

phase voltage seen by the relay when the voltage of the protected system in nominal. The UR uses the convention that

nominal voltages in a three-phase system are phase-to-phase voltages.

For example, on a system with a 13.8 kV nominal primary voltage, the base quantity is 13800 V. With 14400:120 V delta-

connected VTs, the secondary base quantity and secondary voltage setting is:

(EQ 5.1)

For wye-connected VTs, the primary and secondary bases quanitities are as before, but the secondary voltage (here a

phase-to-phase ground value) is:

(EQ 5.2)

Many settings are common to most elements and are discussed below:

•

FUNCTION setting:

This setting programs the element to be operational when selected as “Enabled”. The factory

default is “Disabled”. Once programmed to “Enabled”, any element associated with the function becomes active and all

options become available.

•

NAME setting:

This setting is used to uniquely identify the element.

•

SOURCE setting:

This setting is used to select the AC source to be monitored. See the Introduction to AC Sources

section later.

•

PICKUP setting:

For simple elements, this setting is used to program the level of the measured parameter above or

below which the pickup state is established. In more complex elements, a set of settings may be provided to define the

range of the measured parameters which will cause the element to pickup.

NOTE

13800

14400

----------------

120

×

115 V

=

13800

14400

----------------

120

3

----------

×

66.4 V

=

Summary of Contents for D30D00HCHF8AH6AM6BP8BX7A

Page 10: ...x D30 Line Distance Protection System GE Multilin TABLE OF CONTENTS...

Page 374: ...5 248 D30 Line Distance Protection System GE Multilin 5 10 TESTING 5 SETTINGS 5...

Page 398: ...6 24 D30 Line Distance Protection System GE Multilin 6 5 PRODUCT INFORMATION 6 ACTUAL VALUES 6...

Page 410: ...7 12 D30 Line Distance Protection System GE Multilin 7 2 TARGETS 7 COMMANDS AND TARGETS 7...

Page 444: ...9 24 D30 Line Distance Protection System GE Multilin 9 5 FAULT LOCATOR 9 THEORY OF OPERATION 9...

Page 576: ...B 102 D30 Line Distance Protection System GE Multilin B 4 MEMORY MAPPING APPENDIX B B...

Page 616: ...D 10 D30 Line Distance Protection System GE Multilin D 1 IEC 60870 5 104 PROTOCOL APPENDIX D D...

Page 628: ...E 12 D30 Line Distance Protection System GE Multilin E 2 DNP POINT LISTS APPENDIX E E...

Page 636: ...F 8 D30 Line Distance Protection System GE Multilin F 3 WARRANTY APPENDIX F F...

Page 646: ...x D30 Line Distance Protection System GE Multilin INDEX...