*(.&

24

DIAC / DIFC / DSFC Digital Overcurrent Protection

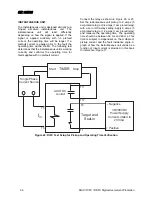

HARDWARE DESCRIPTION

Case

DIAC and DSFC

The DIAC and DSFC relays consist of a case,

cover, support structure, and a connection plug

to make up the electrical connection. The case is

shown in Figures 20 and 22. The external con-

nections are shown in Figure 18. It has 10 con-

nection points and a CT shorting bar. As the

connection plug is withdrawn the trip circuit is

broken prior to the current shorting bar engage-

ment. The window provides visual indication of

the CT shorting.

DIFC

The DIFC relays consist of a molded case,

cover, support structure, and a connection plug

to make up the electrical connection. The case is

shown in Figures 20 and 21. The external con-

nections are shown in Figure 19. It has 14 con-

nection points and a visible CT shorting bar. As

the connection plug is withdrawn the trip circuit is

broken prior to the current shorting bar engage-

ment. The window provides visual indication of

the CT shorting.

Adjustments

All customer settings are accessible from the

front of the relay. The cover must be removed to

gain access to the settings. The cover has provi-

sions for a sealing “wire.” The settings are left to

right, pickup current level for the time element,

time dial, curve selection, frequency / reset time,

pickup current level for the instantaneous ele-

ment, and the instantaneous element time delay.

The settings are all calibrated and are set by

turning the rotary switch to the desired value.

The switches are recessed; a small screwdriver

is required to make the adjustment.

The relay may be supplied with one of three

pointer styles as shown. The color is the color of

the indicator, note the arrow location, all

switches are shown in the 9:00 position.

The TOC pickup current is set directly in Amps

with two rotary switches. An arrow is used to in-

dicate setting position. Setting the TOC or the

IOC pickup current between, but not including 0

and a value less than minimum 0.5 (5 amp) or

0.1 (1 amp) will result in the relay defaulting to its

minimum setting. Setting the TOC or IOC pickup

current to 0 will disable their respective ele-

ments. Although the time dial can be set to a

value less than minimum the relay will use the

minimum setting.

The relay also provides a front panel trip circuit

test. An actuating lever that must be pulled and

then lifted is provided to trip the device con-

nected to the relay. The level directly operates

the trip contacts.

3RLQWHU VW\OHV

<HOORZ

2UDQJH

:KLWH

Targets And Indicators

The yellow pick-up LED will come on solid for the

TOC function when the input current to the relay

is higher than the set point. The location of the

LED is between the frequency/reset switch and

the IOC pickup level switch.

It may be desirable to know when the relay is

powered up and operating. The relay must be

energized at or above 95% of the minimum pos-

sible setting and below pick-up set point. To ac-

tivate, turn the SELECT switch one step clock-

wise or one step counterclockwise. This will

cause the pickup LED to blink at 4 second inter-

vals while current is below the pick-up set point.

Minimum current is 95% of minimum TOC

pickup setting for both the 1amp and 5 amp

models. A blinking LED indicates the microproc-

essor is executing code and outputting signals.

The relay uses a target and seal-in unit as its

tripping element. The relays have one TOC tar-

get and one IOC target. The targets are me-

chanically latched when the function trips. The

trip contacts will remain closed until the trip cir-

cuit current drops below 0.19 A.

NOTE: Do not attempt to reset the trip target

while DC is still applied – this may damage

the output contact.

Summary of Contents for DIAC

Page 2: ......