GE

HEALTHCARE

D

IRECTION

2307224-100, R

EVISION

6

D

ISCOVERY

LS S

YSTEM

S

ERVICE

M

ANUAL

Chapter 8 - System QC, Calibration and Functional Tests

Page 257

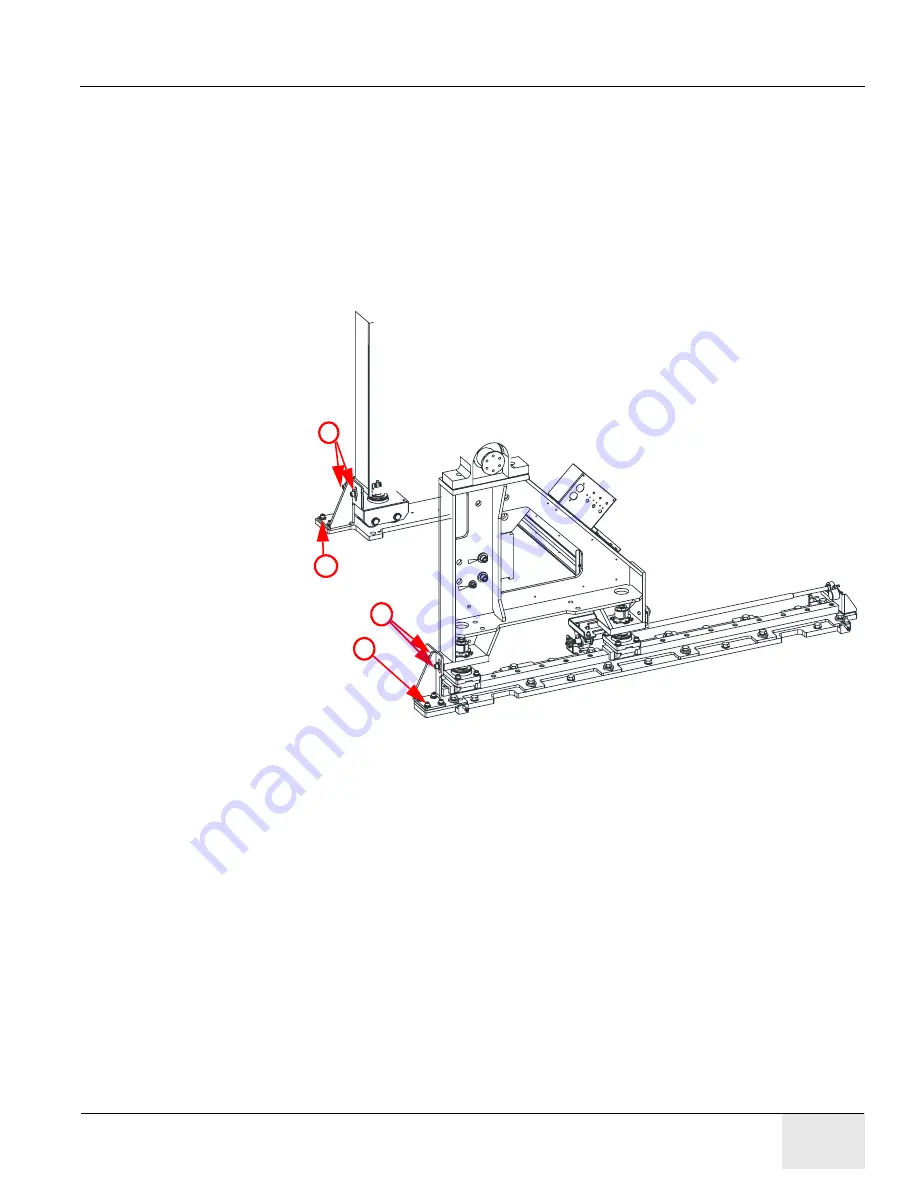

11.) Refer to

. Move the gantry to its home position, and secure it to the mechanical

stoppers, adjusting the screws of the mechanical stoppers as follows:

a.) Remove screws marked

2

.

b.) Loosen screws marked

1

.

c.) Fasten both brackets to the gantry legs with screws marked

3

, making sure that the bases

of both brackets remain resting on the baseplate at all times.

The gantry can now be moved within the range of movement allowed by the oval holes

holding the screws marked

1

.

d.) Move the gantry to enable insertion of the screws marked

2

, and fasten them tightly.

e.) Fasten screws marked

1

tightly.

Figure 8-18:

Mechanical Stoppers Adjustment Screws

12.) Tighten all the baseplate screws that were previously loosened.

13.) After VQC confirms that the Gantry is aligned within specifications, adjust the rear high-load

roller adjuster to a torque of 30 Nm so that the roller rests firmly on the floor.

14.) Replace the bracket that was removed in Steps 3 and 4 of Section

15.) Perform a Well Counter Correction Calibration.

Note:

• Well Counter calibration is performed after running the VQC procedure that is described in

• The full Well Counter Correction procedure is described in the

PET Advance Operator Manual,

Direction 2280383-100

in the sections

: Prepare the Phantom for 2D Well Counter Correction

and

Prepare the Phantom for 3D Well Counter Correction

(if needed).

1

3

2

3