[EN] English - K0394 Issue 3

Installation

7

Installation

This section shows how to install and connect the DPI 104.

Warning:

To prevent an explosion or fire, use only the GE specified battery

and external supply.

DPI 104 Battery

Use the procedures in Table 4 to install or replace the battery.

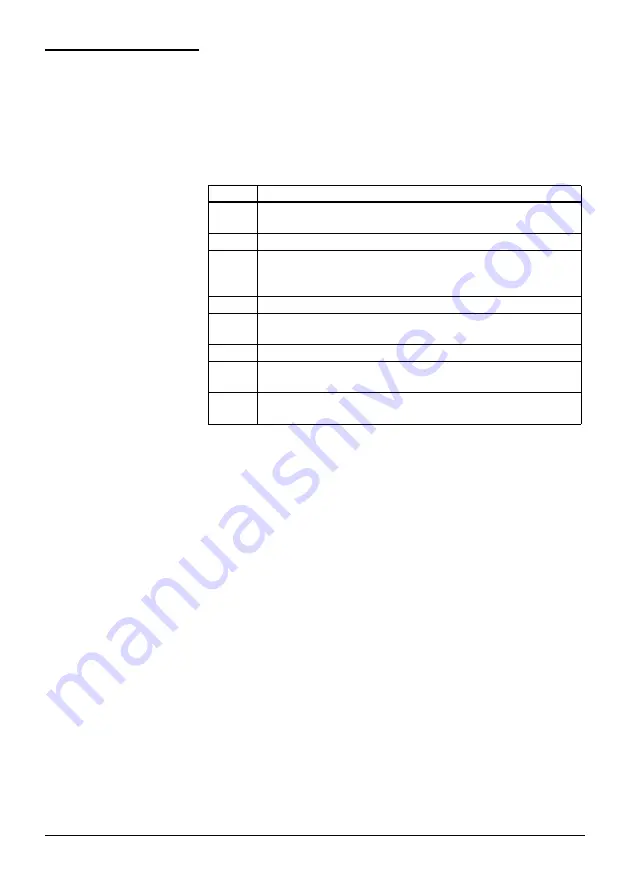

Table 4: Installation procedures - Battery

DPI 104 position

Attach the DPI 104 in a safe configuration that prevents unwanted

stress (for example vibration, physical impact, shock, mechanical

and thermal stresses).

To get the best installation position, turn the pressure connector

(A1: item 4) and the display bezel (A1: item 6) to give the best view of

the display (Figure B1). End stops set the limits in each axis.

CAUTION: Do not use force to turn the pressure connector or the

bezel farther than the end stops. Using force can damage the

instrument.

Step

Procedure

1

If applicable, set the power to off and isolate the external

power supply.

2

Remove the display bezel (Figure A1.2).

3

Make sure that the o-ring [A1: item 7] and the related surfaces

are serviceable. Use only original parts supplied by the

manufacturer.

4

Remove the battery clamp [A1: item 10].

5

If applicable, disconnect the battery connector [A1: item 8] and

*discard the used battery.

* Use an applicable recycling facility.

6

Attach the battery connector [A1: item 8] to the new battery.

7

Install the new battery (Figure A1.3) and re-attach the battery

clamp [A1: item 10].

8

Push the display bezel [A1: item 6] back into position until it is

fully engaged.