Issue 1

4-2 Pressure indicator operation (MC 620)

K0449 - [EN] English

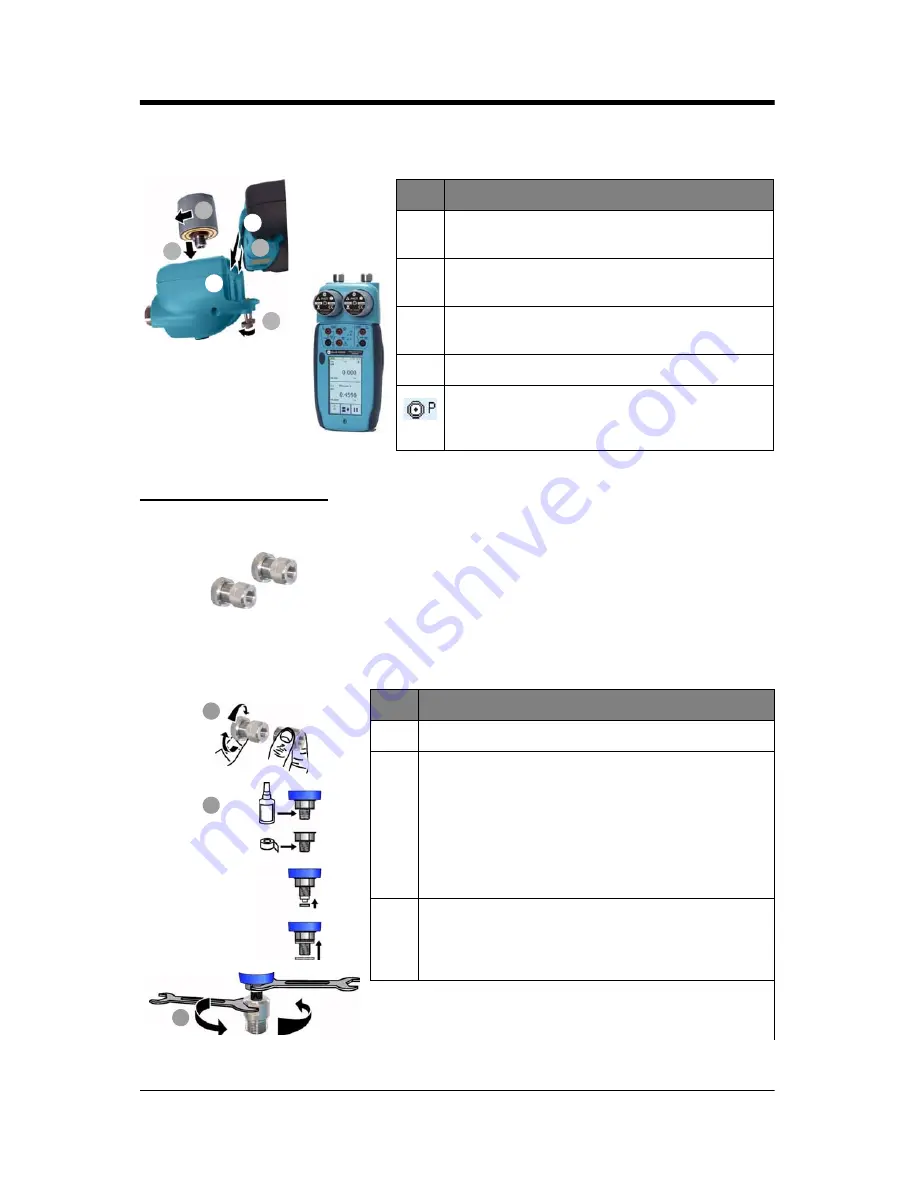

4.2.1 Assembly instructions

4.3 Pressure

connections

WARNING: Pressurized gases and fluids are dangerous.

Before you attach or disconnect pressure equipment,

safely release all the pressure.

The pressure ports for external equipment use “Quick fit”

pressure adaptors; see

Section 1.4 (Accessories)

. These are

easy to remove, change and install.

4.3.1 Procedure (to attach external equipment)

a

b

4

3

2

1

Step

Procedure

1.

Align the two slots (a) on the calibrator with the two

posts (b) on the module carrier.

2.

When the posts are fully engaged in the slots,

tighten the two screws until they are hand tight.

3.

Attach one or two PM 620 modules with the correct

range and type.

4.

Tighten each one until it is hand tight only.

When this symbol flashes at the top of the display, it

shows there is communication between the module

and the calibrator.

Step

Procedure

1.

Remove the adaptor from the pressure port.

2.

Use an applicable seal for the pressure connection:

a.

NPT type: Use an applicable sealant on the thread.

b.

BSP (parallel) type: We recommend a bonded seal

at the bottom.

c.

BSP (parallel) type, 100 bar (1500 psi) or less: a

bonded seal at the top is permitted.

3.

Attach the adaptor to the external equipment; if

necessary use one of the alternative adaptors in

Section 1.4 (Accessories)

, then tighten to the applicable

torque.

Continued

1

2

NPT

a.

c.

(G) / BSPP

P

d

100 bar

b.

(G) / BSPP

3

Summary of Contents for Druck DPI 620

Page 8: ...Issue 1 viii About this manual K0449 EN English ...

Page 18: ...Issue 1 1 6 Instrument parts accessories and options K0449 EN English ...

Page 38: ...Issue 1 2 20 Prepare the instrument K0449 EN English ...

Page 52: ...Issue 1 3 14 Electrical and IDOS operations K0449 EN English ...

Page 60: ...Issue 1 5 2 Instrument communications K0449 EN English ...

Page 64: ...Issue 1 6 4 Datalog operation K0449 EN English ...

Page 68: ...Issue 1 7 4 Documenting functions K0449 EN English ...

Page 80: ...Issue 1 9 2 Maintenance procedures K0449 EN English ...

Page 82: ...Issue 1 10 2 General specification K0449 EN English ...

Page 83: ...Customer service Visit our web site www gesensinginspection com ...

Page 84: ......