Issue 1

4-6 Hydraulic pressure operation (PV 623)

K0457 - [EN] English

4.7 Drain all the

hydraulic fluid

In some conditions, it is necessary to fully drain the hydraulic

fluid from your PV 62x pressure station; for example:

•

if you are using water and the storage or operating

temperature is going to be less than 4°C (39°F)

•

if there is a long period of storage

•

if there is unwanted material in the hydraulic fluid

4.7.1 Preparation

To drain the instrument, we recommend these items:

•

the applicable skin and eye protection

•

a container that is large enough to hold the hydraulic fluid

and prevent contamination of the work surface

•

applicable materials to make sure the instrument and the

area stay clean; see Chapter 6 (Maintenance procedures)

4.7.2 Procedure

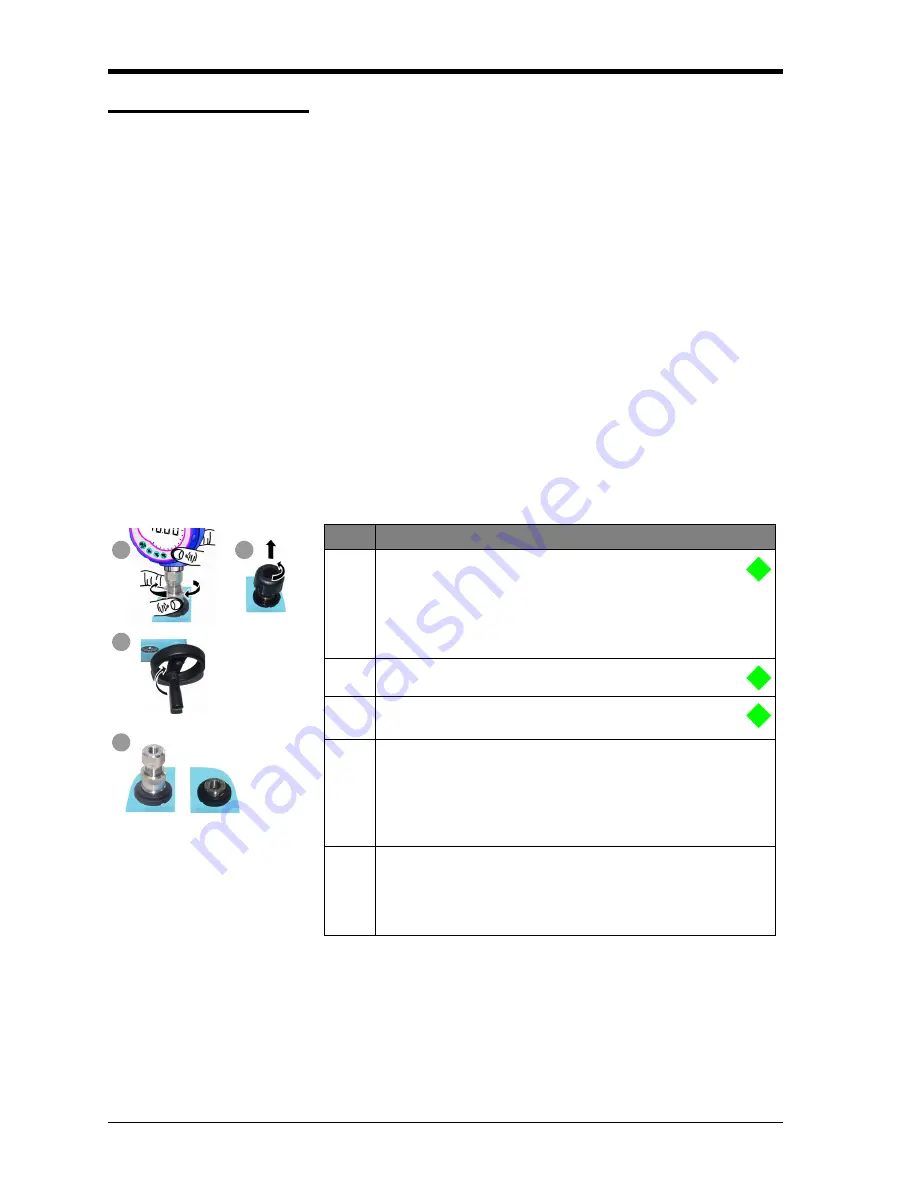

1

2

4

+

3

Step

Procedure (Drain all the fluid)

1.

If applicable, release the pressure (Section 4.3) and

remove the device (Section 4.4).

Note:

If it is attached, we also recommend you remove the

DPI 620 calibrator; see Chapter 5 (Pressure calibrator

operation (DPI 620)).

2.

Remove the hydraulic pressure release valve.

3.

Wind the volume adjuster wheel fully clockwise; this

moves the fluid out of the pressure mechanism.

4.

Put a container below the instrument then tilt the instrument

up until

all

the fluid has come out. To discard the hydraulic

fluid, obey all the local health and safety procedures.

Note:

Fluid comes out of the test port and the connection

for the pressure release valve.

5.

To flush out fluids that contain unwanted material, refill the

system and repeat steps 3 and 4.

Note:

To prevent contamination use only one type of

hydraulic fluid in the instrument.