16

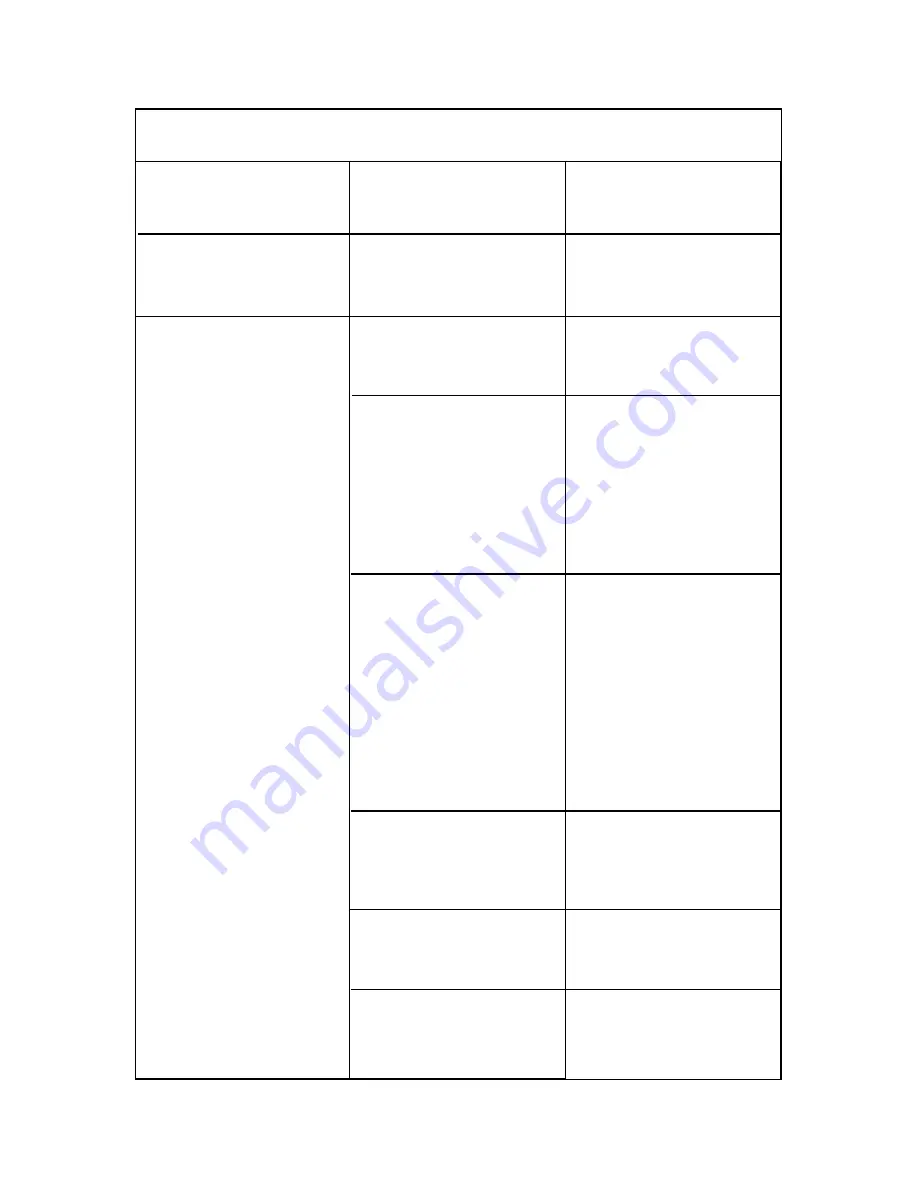

REMEDIES

Refer to Section 2.9 for proper-

ly setting concentrate and

recycle valves

See above.

Check the water temperature.

If needed, install a hot/cold

tempering valve. Permeate

production rate is dependent on

77°F (25°C). Refer to Section

2.5 (Temperature Correction

Factor).

Refer to Section 2.18 for cor-

rect membrane element

installation procedure.

Membrane elements with

damaged brine seals may be

returned for repair. For low

permeate production, it is

wise to test the permeate pro-

duction of each membrane

element.

Refer to Section 2.18 for cor-

rect membrane element

installation.

Flush and/or clean the

machine.

Reduce permeate line back-

pressure. Check for restric-

tions in permeate plumbing.

POSSIBLE CAUSES

Concentrate or recycle valve to

far open

Low operating pressure

Machine operating on cold

water

Membrane elements installed

incorrectly

Brine seal has “rolled” or been

damaged

Dirty or fouled membrane

elements

Backpressure on the permeate

line

PROBLEM

Low operating pressure

(continued)

Low permeate production

.

T R O U B L E S H O O T I N G G U I D E

Summary of Contents for E2 Series

Page 18: ...Figure 2 4 Membrane Element Direction for Installation 14 ...

Page 24: ......