3

minimum of 20 seconds have elasped. If

necessary, the heater will cycle with a turn on

temperature of 32°F (0°C) and a turn off

temperature of 35.6°F (2°C)

To insure the motor completes a full

revolution, the control checks to see the motor

is “not home” for at least 10 seconds and the

feeler arm is “in” for at least 10 seconds. Once

these two conditions are met and the motor

reaches home position, the harvest cycle will

be complete and the motor will turn off.

The harvest cycle consists of one

complete revolution of the ejector to sweep the

cubes from the mold and drop them into the

ice bucket. If the harvest cycle is not complete

within 7 minutes, the control will assume that a

cube is blocking the completion of a cycle and

will initiate a harvest fix mode. If the harvest

cycle is not complete within 30 minutes, the

control will assume some other problem has

occurred and will enter the fault mode.

Harvest Fix

If the harvest cycle is not complete

within 7 minutes, the control will enter a “Harvest

Fix” mode. In the harvest fix mode, the

temperature of the mold will be raised in an

attempt to melt any cubes that are jammed. The

control will turn the heater off when the

thermistor temperature reaches 68°F (20°C)

and turn it back on again at 59°F (15°C). During

this time, the motor will be cycled off for 10

seconds of every minute. If the motor reaches

the home position, a second revolution of the

ejector will occur to verify there is no more

blockage. When the second revolution is

complete, the control will enter the freeze cycle

without allowing a water fill to insure against a

double shot of water. The control will enter a

Fault Mode if a harvest cycle (including harvest

fix) is not complete within 30 minutes. Potential

causes for a harvest to take longer than 30

minutes are:

•

Stuck ejector - caused by a cube that was

not cleared or a mechanical problem

•

Bad heater - caused by the heater, control

board or thermal cutout (TCO)

•

Bad motor - caused by motor or control

board

•

Motor home position not operating - caused

by control board or loose magnet - the result

will be continuous ejector operation

•

Thermistor - open or shorted

THERMISTOR

˚F

˚C

-40

-40

35.6

2

39.2

4

50

10

59

15

68

20

77

25

10K

176

80

207K

25.37K

23.27K

18.07K

14.75K

12.11K

1.67K

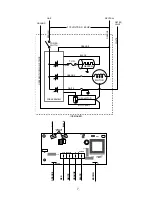

Water Fill

When harvest is complete, the icemaker

will enter the “Water Fill” cycle. The amount of

water entering the mold is controlled by

temperature. Before any water enters, the mold

must reach a temperature of 35.6°F (2°C). This

“prechilling” of the mold allows the thermistor

to better detect the level of the water. Water

entering the icemaker will cause the mold

temperature to change, effecting the resistance

of the thermistor.

The icemaker thermistor has a negative

coefficient. That is, an increase in temperature

will cause a decrease in resistance. The chart

below shows the most common values used

by the electronic control.

Once the mold has completed harvest

and cooled to 35.6°F (2°C), a first fill will be

initiated. This first fill activates the water valve

for 5.1 seconds. After this fill, there will be a 15

second delay before determining if the icemaker

is sufficiently full. If the temperature exceeds

39.2°F (4°C) after the 15 second delay, the

icemaker will end the water fill cycle and start

Summary of Contents for Electronic Icemaker

Page 10: ...8 ...