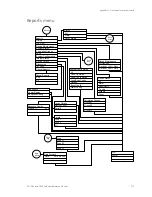

Appendix B: Worksheets

EST iO64 and iO500 Technical Reference Manual

225

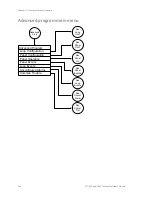

Code

(4-digit

coded

output)

CID

Disable

☐

Yes

☐

No

NET

☐

Yes

☐

No

Dialer

☐

Acct 1

☐

Acct 1 & 2

☐

Acct 2

☐

None

Code

(4-digit

coded

output)

CID

Pre

alarm

☐

Yes

☐

No

NET

☐

Yes

☐

No

Dialer

☐

Acct 1

☐

Acct 1 & 2

☐

Acct 2

☐

None

Code

(4-digit

coded

output)

CID

Alarm

verify

☐

Yes

☐

No

NET

☐

Yes

☐

No

Dialer

☐

Acct 1

☐

Acct 1 & 2

☐

Acct 2

☐

None

Code

(4-digit

coded

output)

CID

Maintenance

alert

☐

Yes

☐

No

NET

☐

Yes

☐

No

Dialer

☐

Acct 1

☐

Acct 1 & 2

☐

Acct 2

☐

None

Code

(4-digit

coded

output)

CID

Test

☐

Yes

☐

No

NET

☐

Yes

☐

No

Dialer

☐

Acct 1

☐

Acct 1 & 2

☐

Acct 2

☐

None

Code

(4-digit

coded

output)

CID