LCD

GRAPHIC

FACTORY

FUNCTION

DISPLAY

SETTING

DESCRIPTION

SETTING

6-3

* 07

TRQ BOOST1

TORQUE BOOST #1

2.0

Torque boost for motor #1 can be set to

optimize the V/Hz characteristics of the

drive according to the type of load the

motor will see. The factory setting of

zero (0) causes the drive to automatic-

ally select the boost level according to

its torque calculations

0.0:

Automatic

0.1 - 0.9

Variable torque loads (Fans)

1.0 - 1.9:

Proportional torque loads (Machine tool spindle)

2.0 - 20:

Constant torque loads (Conveyor)

NOTE : Function Code 29 setting will affect this

Function Code.

CAUTION:

When using Automatic (0.0 setting) be sure Function Codes

87 & 88 are set for the connected motor. With the motor connected,

not rotating, and with load disconnected, if possible, activate Function

Code 90 (Tuning) to reset Function Code 91 & 92.

* 08

ELCTRN OL

ELECTRONIC OVERLOAD

1

The Drive's Electronic Overload can be selected to

help protect the motor from thermal overload due to

various operating conditions. Selection should be

based on operating conditions, type of load, motor

thermal characteristics and the applicable NEC and

local electrical code requirements.

The motor thermal characteristics and the diagram

shown in Function Code 09 should be reviewed, and

their characteristics coordinated, to determine what

is the protection level available with the drive/motor

combination, and what additional protection will be

required. (Refer to Function Code 09.)

0:

Inactive (Internal thermal overload device)

1:

Active (Review motor thermal characteristics)

2:

Special factory setting (Consult Company)

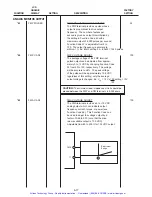

Volts

Hz

Base Frequency

20.0

2.1

0

1.0 - 1.9

0.1 - 0.9

2.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com