GEH-5304A

11

Mounting may be either horizontal or vertical for these bearing life determinations, as long as no axial

load (i.e., suspended load) other than the weight of the armature is present if vertical.

5.

Special Load Considerations

Where the load is overhung beyond the motor shaft extension or greater bearing life is desired, the

application should be referred to GE Industrial Systems.

6.

Pinion Drives

While Kinamatic

motors are not designed for overhung pinion drives, they may be successfully ap-

plied under suitable conditions. In addition to a radial load, some gears produce thrust load on the

bearing. Complete details of the proposed gearing should be referred to GE Industrial Systems in all

cases.

7.

Thrust Loads

Due to the mounting position or type of drive arrangement, a thrust load may be applied to the motor

shaft. The Kinamatic

motor is designed to permit a limited amount of thrust load. This permissible

load will vary by mounting position and direction of the load due to the weight of the armature. The

permissible load in Table 2 is tabulated by frame diameter and mounting position. These apply to

ball bearings only.

For applications combining thrust and radial loads or where thrust loads exceed the values shown in

Table 2, refer all details to GE Industrial Systems.

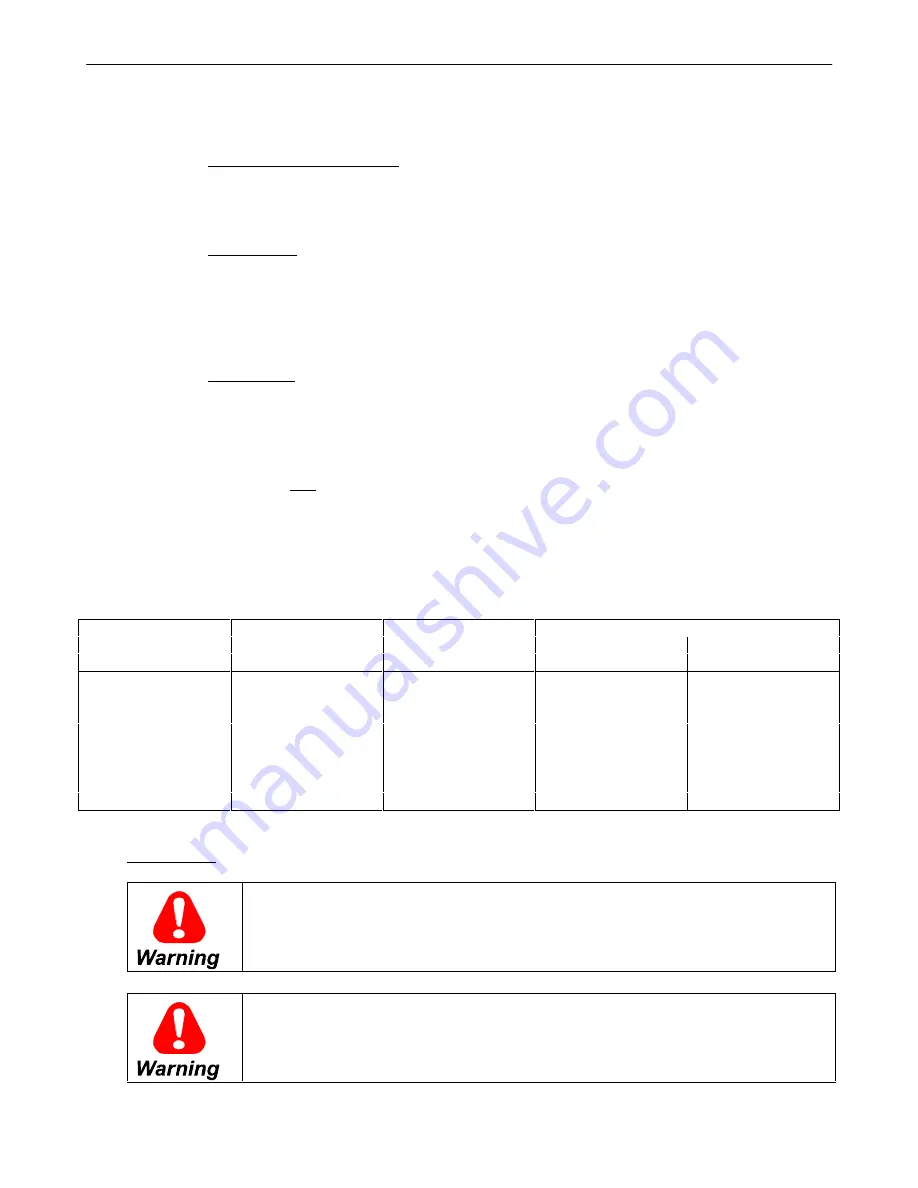

Table 2

Maximum Continuous Thrust Capacity, Lbs.*

Vertical Mounting

Bearing

Horizontal

Thrust Load

Thrust Load

Frame

Size

Mounting

Up

Down

2512

Std-309

350

465

235

2512

O/S-310

400

515

285

2513

Std-309

350

485

215

2513

O/S-310

400

585

265

2812

Std-310

400

550

250

2812

O/S-311

500

650

350

2813

Std-310

400

585

215

2813

O/S-311

500

685

315

*Based on L10 life of 20,000 hours and an average speed not exceeding 2500 RPM.

IV.

OPERATION

Disconnect power before touching any internal part. High voltage may be pres-

ent even when the machine is not rotating. If used with a rectified power sup-

ply, disconnect all AC line connections to power supply. With other power

supplies, disconnect all DC line and field connections. Also disconnect power

from auxiliary devices.

Ground the machine properly to avoid serious injury to personnel. Grounding

must be in accordance with the National Electrical Code and consistent with

sound local practices. One of the bolts holding the conduit box to the unit, ac-

cessible from inside the conduit box, is identified and may be used for attach-

ing a grounding cable.

Summary of Contents for GEH-5304A

Page 26: ...GEH 5304A 26 ues ...

Page 34: ...GEH 5304A 34 Figure 3 Application Information for CD2512AT CD2813AT Frames ...

Page 36: ...GEH 5304A 36 Figure 5 Dimensions Air Openings for CD2512AT CD2813AT Frames ...

Page 38: ...GEH 5304A 38 Figure 6 Accessory Mounting CD2512AT CD2813AT ...

Page 39: ...GEH 5304A 39 Figure 7 Accessory Mounting CD2512AT CD2813AT ...

Page 40: ...GEH 5304A 40 ...

Page 43: ...GEH 5304A 43 Detach and fax or mail to the address noted above ...