GEH-5304A

7

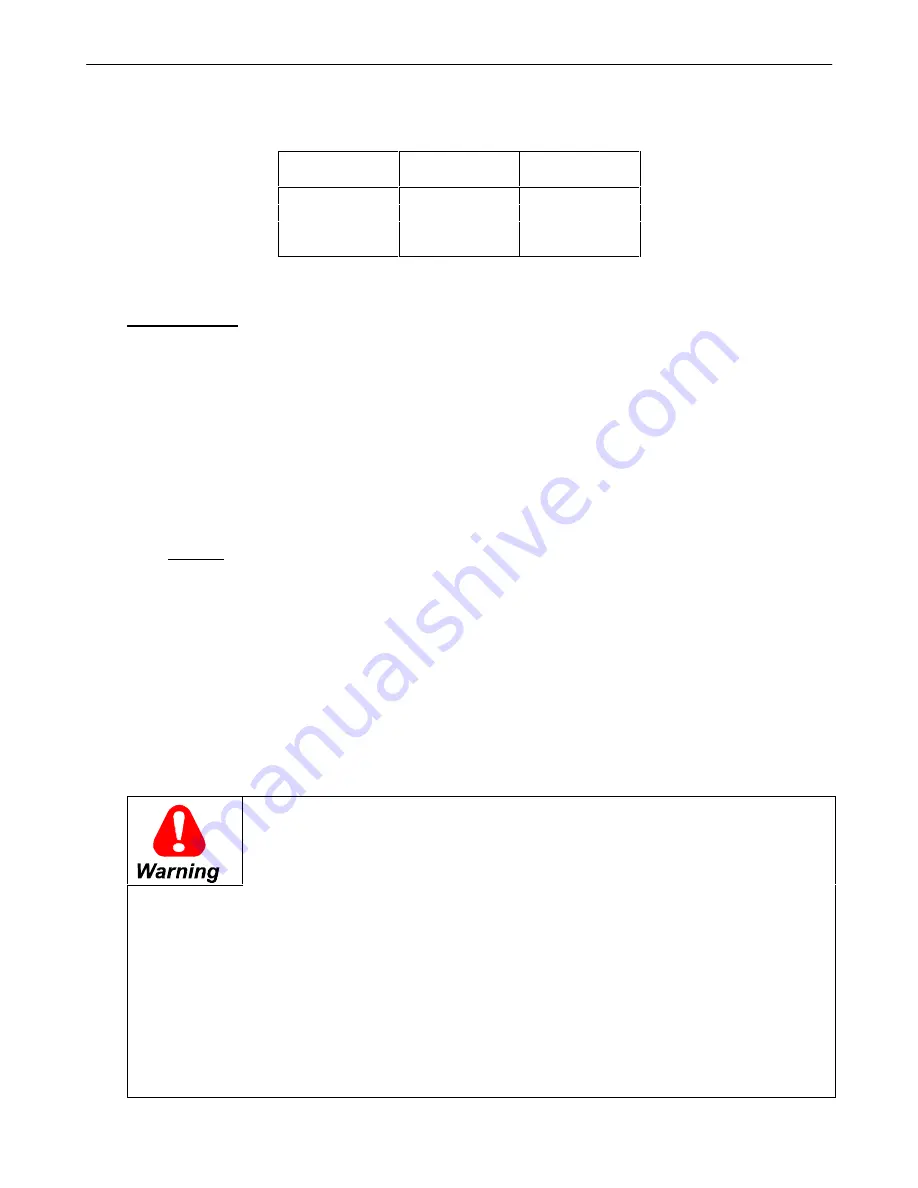

Table 1

Typical Weights**

Motor (Less

Accessories)

Armature

CD2512AT

500

120

CD2513AT

550

135

CD2812AT

650

160

CD2813AT

750

190

**Typical weights. For specific weight, see certified outline.

III.

INSTALLATION

Installation should be in accordance with the National Electrical Code and consistent with all local codes. Cou-

pling, belt and chain guards should be installed as needed to protect against accidental contact with moving parts.

Machines accessible to the public should be further guarded by screening, guard rails, etc. to prevent personnel

from coming in contact with the equipment. Fully guarded covers are supplied on motors and generators. Shaft

guards are supplied on motor generator sets.

Totally enclosed and waterproof motors must have all covers securely in place with gaskets intact in order to ex-

clude dirt, oil and water. It is generally preferred to remove plugs from drain holes at the bottom of the frame to

ensure that no condensation will collect inside the motor. However, if the installation requires plugs to be installed,

they must be removed periodically to make certain that all water is eliminated.

A.

Location

Motors and generators should be installed so that they will be readily accessible for routine inspection and

maintenance. They are suitable for use in ambient temperatures from 0

°

C (32

°

F) to 40

°

C (104

°

F). An ade-

quate supply of clean, dry room air is required for self-ventilated, separately ventilated and blown motors.

Where motors must operate in dirty, wet or contaminated environments, protection in the form of filters or

totally enclosed construction must be used to obtain long life with normal maintenance.

Do not obstruct ventilating openings.

When filters are supplied, service them regularly. Dirty filters shut off ventilating air.

Beware of recirculation. Install motors so that hot exhaust air will not re-enter the motor.

The use of electrical equipment in hazardous locations is restricted by the Na-

tional Electrical Code, Article 500. Original equipment manufacturers and user

customers must read, understand and apply these rules for installation and use

of all equipment in such locations and consult local code inspection and en-

forcement agencies, as necessary, to ensure compliance. Motors listed by

Underwriters Laboratories, Inc. for use in specific locations have been designed, tested and ap-

proved for use in such locations only.

Sections 501-8 and 502-8 now permit the use of totally enclosed motors with positive pressure

ventilation or totally enclosed inert-gas-filled motors (Class I locations only), when installation

and operation conform to certain requirements.

Motors for Class I locations must have leads sealed at the frame exit and an explosion-proof

conduit box. See Sections 501-4 and 501-5.

Motors for Class II locations must have leads sealed at the frame exit and a dust-ignition-proof

conduit box. See Sections 502-4 and 502-5.

Summary of Contents for GEH-5304A

Page 26: ...GEH 5304A 26 ues ...

Page 34: ...GEH 5304A 34 Figure 3 Application Information for CD2512AT CD2813AT Frames ...

Page 36: ...GEH 5304A 36 Figure 5 Dimensions Air Openings for CD2512AT CD2813AT Frames ...

Page 38: ...GEH 5304A 38 Figure 6 Accessory Mounting CD2512AT CD2813AT ...

Page 39: ...GEH 5304A 39 Figure 7 Accessory Mounting CD2512AT CD2813AT ...

Page 40: ...GEH 5304A 40 ...

Page 43: ...GEH 5304A 43 Detach and fax or mail to the address noted above ...