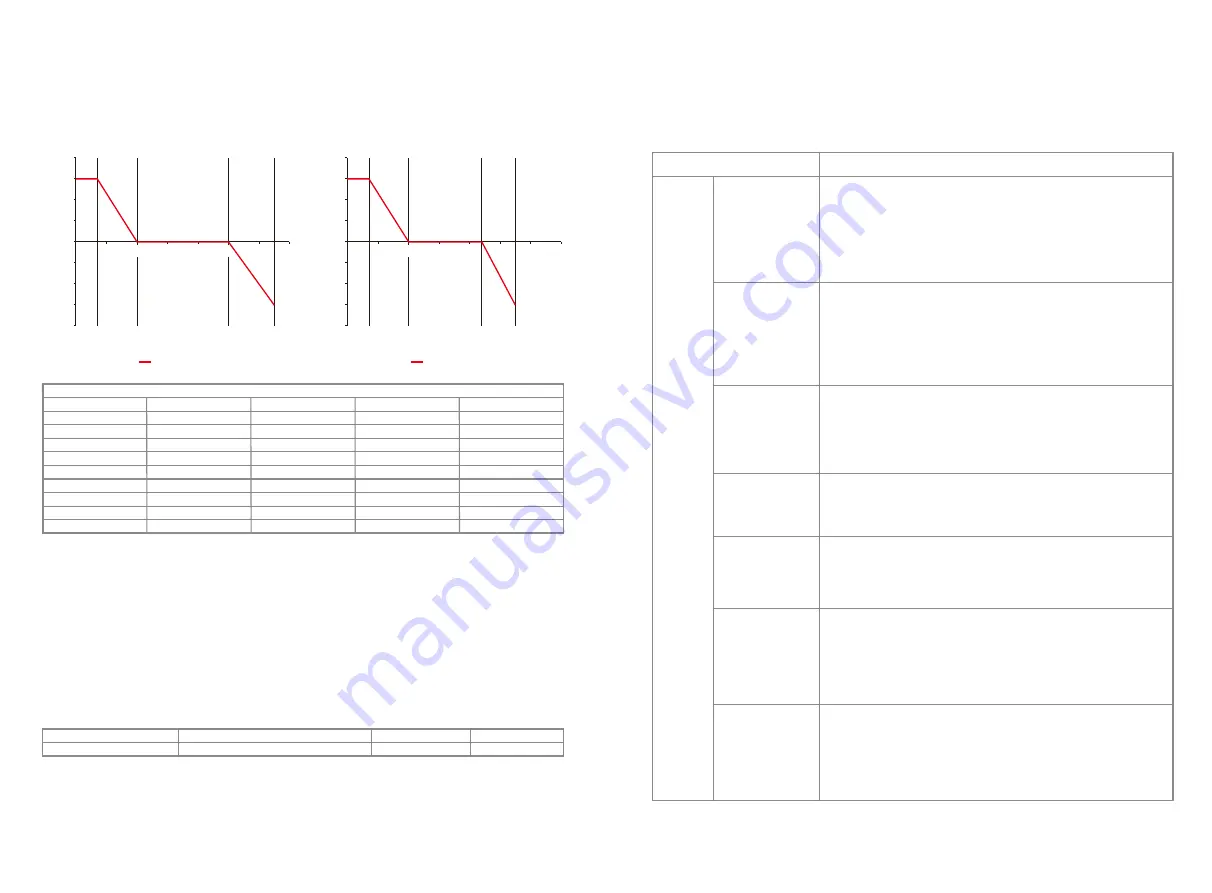

5.6.3 QU Curve Mode

QU curve mode can be modified by Modbus communication, specifically according to the

inverter Modbus address and Modbus register value, according to the set range to set the

corresponding value.

5.6.4 Power Recovery Rate

The power recovery rate can be modified by Modbus communication, specifically according to

the inverter Modbus address and Modbus register value, according to the set range to set the

corresponding value.

Function

Power recovery rate Settings

The default value (Australia & New Zealand)

16

(

16%Pn/min

)

Register

40536

Setting range

5~100

If you need to change the above Settings, please contact our after-sales service.

40%

V1

V2

V3

V4

LEADING

LEADING

VAR/RATED, VA (%)

INVERTER VOLTAGE, V

var characteristic curve

LEGEND:

30%

20%

10%

0%

10%

200

210

230

240

260

270

20%

30%

40%

220

250

40%

V1

V2

V3

V4

LEADING

LEADING

VAR/RATED, VA (%)

INVERTER VOLTAGE, V

var characteristic curve

LEGEND:

30%

20%

10%

0%

10%

200

210

230

240

260

270

20%

30%

40%

220

250

QU curve Mode

Function

QU curve mode enable or disable

V1 voltage ratio

Q1 reactive power ratio

V2 voltage ratio

Q2 reactive power ratio

V3 voltage ratio

Q3 reactive power ratio

V4 voltage ratio

Q4 reactive power ratio

Default value (Australia)

0

900 (207 V)

300 (30%*Pn)

957 (220 V)

300 (30%*Pn)

1087 (250 V)

300 (30%*Pn)

1152 (265 V)

300 (30%*Pn)

Default value (New Zealand)

0

900

(

207 V)

300

(

30%*Pn)

957 (220 V)

300 (30%*Pn)

1061 (244 V)

300 (30%*Pn)

1109 (255 V)

300 (30%*Pn)

Setting range

“0”or“1”

0~2000

0~600

0~2000

0~1500

0~2000

0~1500

0~2000

0~600

Register

40650

40653

40654

40655

40656

40657

40658

40659

40660

Example: Set the ratio of V1 voltage to 1100, corresponding to the rated voltage of 230 V, V1

=

230

* 110% = 253 V.

Example: Set Q1 reactive power ratio to 300, corresponding reactive power

Q1=30%*

rated

power.

6 Troubleshooting

If the Inverter is not able to work properly, please refer to the following instructions before

contacting your local service. If any problems arise, the red (FAULT) LED indicator on the front

panel will light up and the LCD screen will display relevant information. Please refer to the

following table for a list of error messages and associated solutions.

1. Disconnect DC switch, take off DC connector, check the impedance between

PV (+) & PV(-) to earth.

2. If impedance is less than 100 kΩ, please check the insulation of PV string wiring

to earth.

3. If impedance is large than 100 kΩ, please contact local service office.

4. Take off AC connector, measure the impedance between neutral wire and PE

line. If it is larger than 10KΩ, please check AC wiring.

1. Grid is not connected.

2. Check if the power cable is connected with grid.

3. Check the availability of power from the grid.

1. Check whether PV open circuit voltage is higher or too close to the maximum

input voltage.

2. If the problem still persist when PV voltage is less than the maximum input

voltage, contact local service office for help.

1. The internal temperature is higher than normal specified value.

2. Reduce ambient temperature.

3. Move the inverter to a cool place.

4. If the problem still exists, contact local service office for help.

1. The ground current is too high.

2. Take off the inputs from the PV panel and check the peripheral AC system.

3. When the problem is cleared, reconnect the PV panel and check the Inverter

status.

4. Contact local service office for help if the problem still persist.

1. The PV Inverter will automatically restart within 5 minutes if the grid returns to

normal.

2. Make sure grid voltage conforms to specifications.

3. Make sure neutral (N) wire and PE wire are well connected.

4. Contact local service office for help if the problem still persist.

1. Grid is not connected.

2. Check grid cable connection.

3. Check availability of grid.

Vac Failure

Fac Failure

Type of fault

Troubleshooting

Ground I Failure

Isolation Failure

Over Temperature

PV Over Voltage

Utility Loss

System

Failure

25

26