Summary of Contents for GES-NX2G50OUT

Page 11: ...Pinping diagrams Domestic air conditioner 4ˊPiping diagrams 9 EEV EEV ...

Page 12: ... Operation range Domestic air conditioner 5ˊOperation range 10 ...

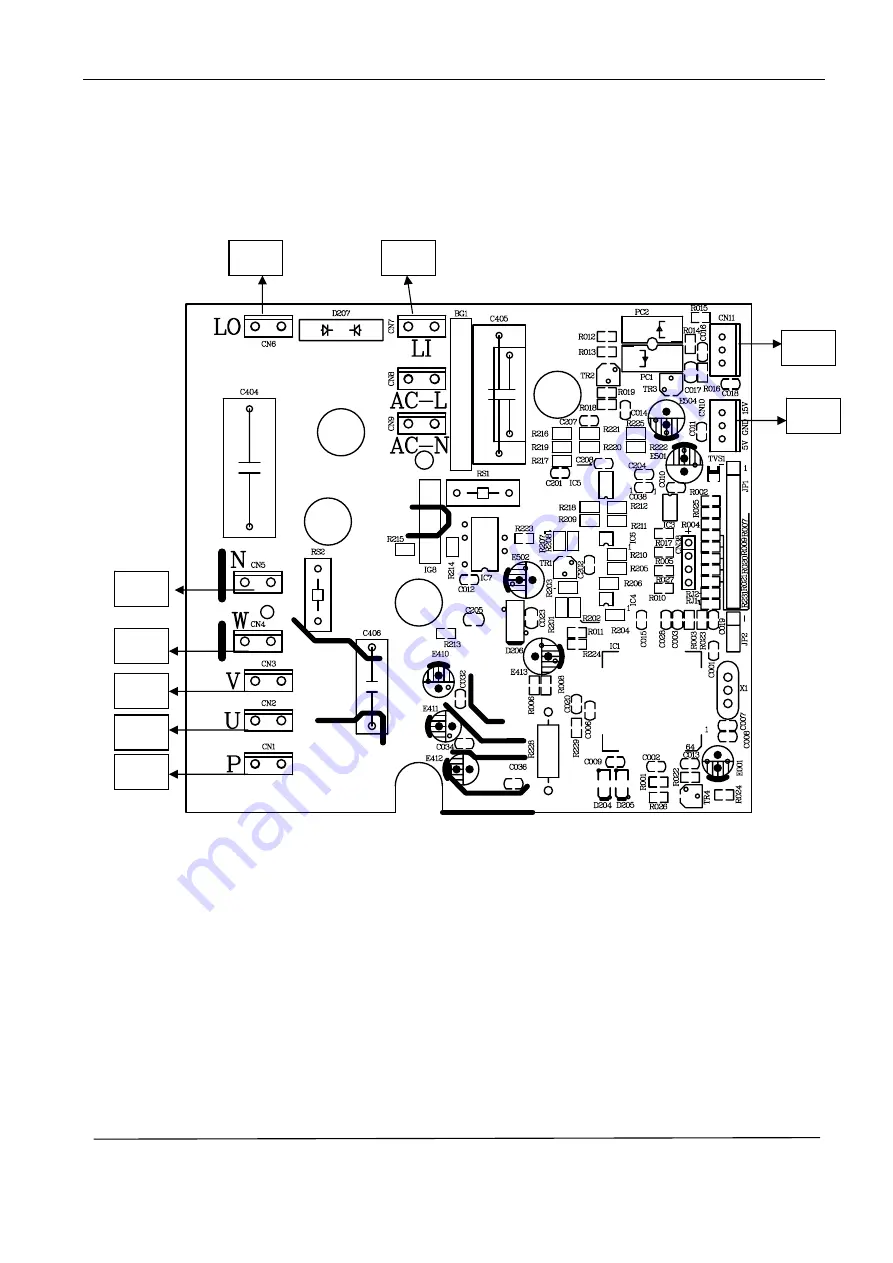

Page 58: ...Circuit diagrams 56 Domestic air conditioner 12 Circuit diagrams ...

Page 59: ...Circuit diagrams 57 Domestic air conditioner ...

Page 62: ...Domestic air conditioner Removal of procedure 1 Removal of Outdoor panel 1 ...

Page 64: ...Domestic air conditioner Loosen the screws and pull the panel Removal of procedure 3 ...

Page 65: ...Domestic air conditioner 2 Removal of Electrical Box Removal of procedure 4 ...

Page 66: ...Domestic air conditioner 3 Removal of Fan and Fan Motor Removal of procedure 5 ...

Page 68: ...Domestic air conditioner 4 Removal of Fan Motor Bracket and Partition Removal of procedure 7 ...

Page 69: ...Domestic air conditioner and remove the reactor Loosen the screw Removal of procedure 8 ...