– 36 –

The auger motor is a reversible AC motor. When

the auger motor turns the auger in the bucket

clockwise crushed ice is produced. When

the auger motor turns the auger in the bucket

counterclockwise cubed ice is released. During

cubed operation, the main board sends 120 VAC

on J7 pin 2 to the motor to activate a reversing

relay inside the motor.

Auger Motor Diagnosing

Operating voltage for the auger motor can be

checked at the auger motor connector or at J7 on

the main board.

J7 on Main Board (Cubed)

• Pin 1 (

tan

) to pin 9 (

orange

): 120 VAC

• Pin 2 (

grey

) to pin 9 (

orange

): 120 VAC

J7 on Main Board (Crushed)

• Pin 1 (

tan

) to pin 9 (

orange

): 120 VAC

• Pin 2 (

grey

) to pin 9 (

orange

): 0 VAC

Auger Motor Removal

1. Remove the ice bucket.

2. Remove the icemaker access cover.

3. Remove two Phillips-head screws.

4. Disconnect the 3-pin connector.

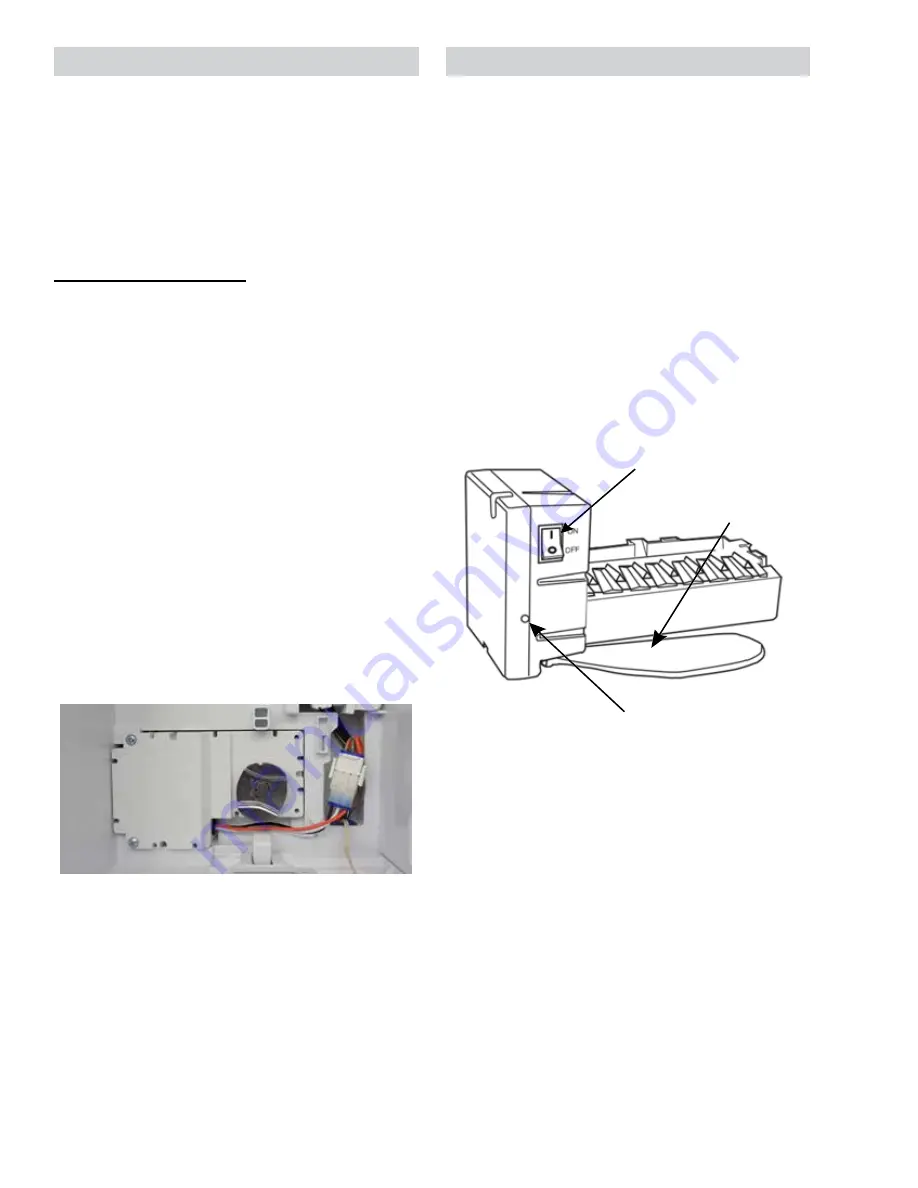

The refrigerator uses an electronic icemaker. The

toggle switch on the front of the icemaker turns

the icemaker ON/OFF. The green LED on the

front of the icemaker indicates that there is power

to the icemaker and the icemaker is turned on.

The icemaker will produce seven cubes per

cycle approximately 100 to 130 cubes in a 24-

hour period, depending on freezer compartment

temperature, room temperature, number of door

openings and other use conditions. The icemaker

will fill with water when the mold body thermistor

of the icemaker cools to 15°F (-10°C). A newly

installed refrigerator may take 12 to 24 hours

to begin making ice cubes. When the bin fills

to the level of the feeler arm (keeping the feeler

arm in the back position), the icemaker will stop

producing ice.

Normal Operation

• To hear a buzzing sound each time the

icemaker fills with water.

• For several cubes to be joined together.

• If ice is not used frequently, old ice cubes will

become cloudy, taste stale and shrink.

(

Continued next page

)

On/Off Switch

Green Power LED

Feeler Arm

Auger Motor

Icemaker