Installation Instructions

2

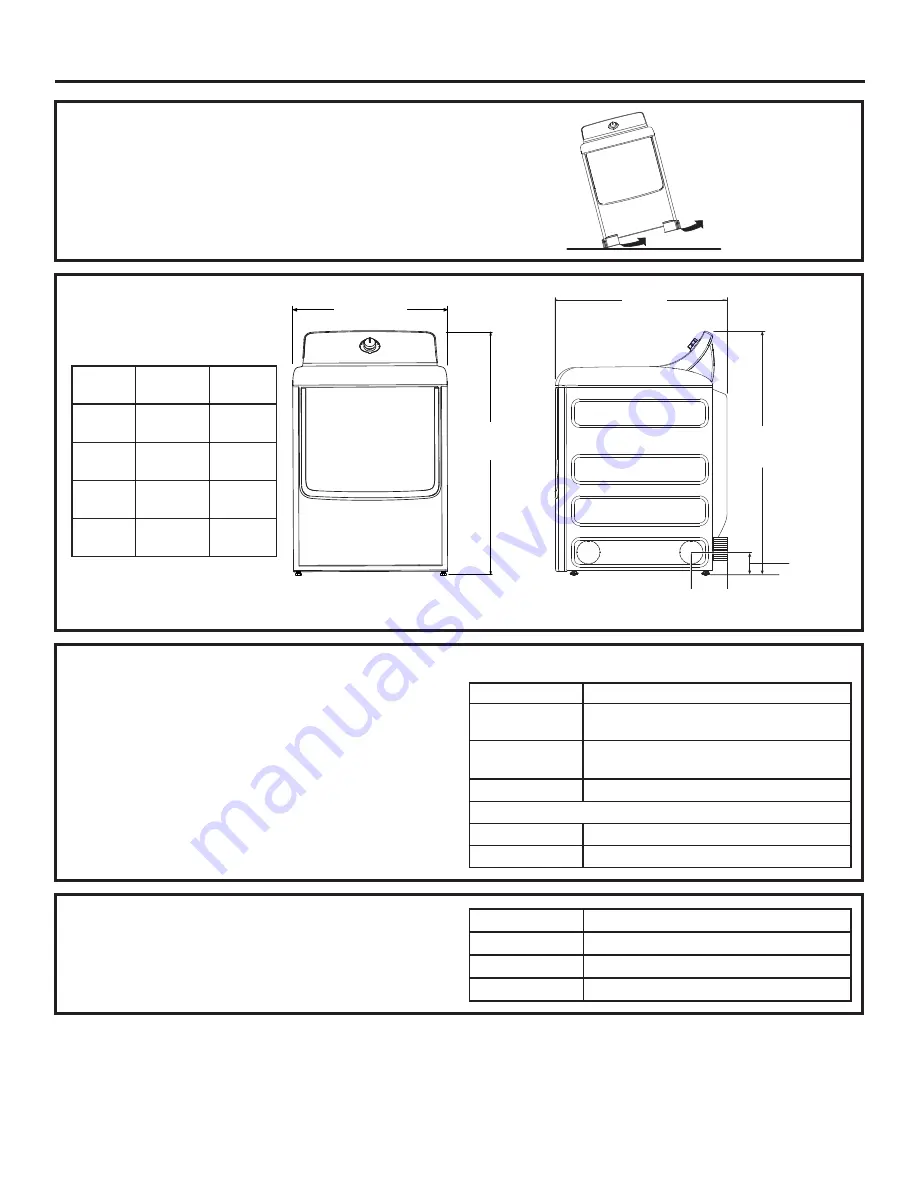

Tilt the dryer sideways and remove the foam

shipping pads by pulling at the sides and breaking

them away from the dryer legs. Be sure to remove

all of the foam pieces around the legs.

Remove the bag containing the literature.

UNPACKING YOUR DRYER

ROUGH-IN

DIMENSIONS

GE Appliances strongly recommends the use of factory

specified parts. These hoses are manufactured and tested

to meet GE Appliances specifications.

GE Appliances strongly recommends the use of new water

supply hoses. Hoses degrade over time and need to be

replaced every 5 years to reduce the risk of hose failures

and water damage.

Parts and Accessories

Order on-line at

GEApplianceparts.com

, 24 hours a day

or by phone at

877.959.8688

during normal business hours.

STEAM WATER HOSES (for steam dryer models only):

ACCESSORIES:

Order on-line at

GEApplianceparts.com

, 24 hours a day or

by phone at

877.959.8688

during normal business hours.

Part Number

Accessory

PM14X10056

Dryer door opening vent brush

WX14X10007

LintEater™ Dryer rotary tube brush

PM08X10085

Flexible Metal Dryer Transition Duct

Part Number

Accessory

WE25X20060

Complete Kit (hoses, Y-adapter, washers)

or

WE49X25794

Kit (Short hose, Y-adapter, washers)

and

WE1M847

Long Hose

OR SEPARATELY

WE1M847

Long Hose

and

WE1M848

Short Hose

4 5/8”

(11.7 cm)

Y

X

27”

(68.8 cm)

X

4 1/4”

(10.8 cm)

Side View

Front View

Cubic

Foot

X

Y

6.2

43 3/8”

(110 cm)

26 3/4”

(68 cm)

7.2

43 3/8”

(110 cm)

29 1/2”

(75 cm)

7.4

43 3/4”

(111 cm)

30 1/2”

(78 cm)

7.4 with

steam

45 3/4”

(116 cm)

30 1/2”

(78 cm)