Summary of Contents for GTW220ACK_WW

Page 9: ...9 11 16 2015 Model Graphics GTW460 GTW485 GTW490 GTW680 ...

Page 19: ...Lid Lock Striker Pull the striker from the lid ...

Page 27: ...27 11 16 2015 Four Coil Water Valve On GTW680 Model Video Link ...

Page 34: ...34 11 16 2015 Impeller and Agitators Single Action Agitator Impeller Dual Action Agitator ...

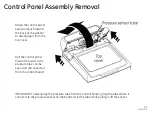

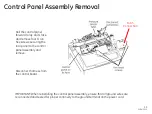

Page 41: ...41 11 16 2015 Top Cover Removal Slide the power cord grommet forward Slide Forward ...

Page 42: ...42 11 16 2015 Top Cover Removal Pull up off of the top cover Pull Up And Off ...

Page 62: ...62 11 16 2015 Schematic ...

Page 63: ...63 11 16 2015 Control Board User Interface J701 J511 J513 J602 J512 J101 J514 J615 J401 ...

Page 64: ...64 11 16 2015 Consumer Error Mode Entry ...

Page 65: ...65 11 16 2015 Consumer Help Indicator ...

Page 66: ...66 11 16 2015 Service Mode Entry ...

Page 67: ...67 11 16 2015 Binary Display Test and Fault Chart ...

Page 68: ...68 11 16 2015 Service Mode Tests ...

Page 69: ...69 11 16 2015 Service Mode Tests ...

Page 70: ...70 11 16 2015 Service Mode Tests ...

Page 71: ...71 11 16 2015 Service Mode Tests ...

Page 72: ...72 11 16 2015 Service Mode Tests ...

Page 73: ...73 11 16 2015 Service Mode Tests ...

Page 74: ...74 11 16 2015 Service Mode Tests ...

Page 75: ...75 11 16 2015 Service Mode Tests ...

Page 76: ...76 11 16 2015 Service Mode Tests ...

Page 77: ...77 11 16 2015 Fault Codes ...

Page 78: ...78 11 16 2015 Fault Codes ...

Page 79: ...79 11 16 2015 Fault Codes ...

Page 80: ...80 11 16 2015 Fault Codes ...

Page 81: ...81 11 16 2015 Warranty ...