15

GEAppliances.com

1.

To enter diagnostics, press and hold

the

MODE

button for 3 seconds until

the Low Salt Alarm screen shows.

2.

Press the

MODE

button 2 times to

advance through Low Salt Alarm

and Salt Efficiency options. See

Programming the Control

for details

on these two options.

3. OPERATION OF DIAGNOSTICS

•

Valve Position –

Press the

RECHARGE

button to

initiate a recharge cycle. Press again to manually index

valve to next position. See

Service: Manually Advance

Recharge Check

for details.

0 – Service

1 – Fill

2 – Brine

3 – Backwash

4 – Fast Rinse

•

Motor Operation –

Two dashes will circulate around

when motor should be running.

•

Position Switch Operation –

– Closed – valve rotating to next position

– Open – valve in position, service, fill, brine, etc.

•

Water Meter –

Indicates whether water is flowing

through valve.

– 000 indicates no water is flowing through the valve

– Open nearby soft water faucet

– 000 to 199(continual) shows water is flowing.

Display repeats for each gallon of water passing through the

meter. Control will beep at every gallon. (1 gallon= 3.78 litres)

– If there is no reading in the display, with faucet

open, check the sensor. Pull the sensor from the

valve outlet port, and pass a small magnet in front

of the sensor. Counter should index in the display.

If counter does not index, check to make sure

harness is connected to board properly. If there is

a reading in the display, there may be a problem

associated with the turbine. Turn off water supply,

close the by-pass valve, and disconnect by-pass valve

from valve body. Check turbine for binding or

restriction due to debris. If this does not correct

the problem, the Timer, Sensor, or Turbine may

require replacement.

4.

Historical data about the softener is available.

•

Press and hold the UP

button to display the number

of days this control has had electrical power applied.

•

Press and hold the DOWN

button to display the

number of recharges initiated by this control since the

model code number was entered.

5.

Press the

MODE

button to return to normal operation

and display.

Service: Set Model (F) Code

1.

To change or check model code, first press and hold the

MODE

button for 3 seconds until the Low Salt Alarm

screen shows.

2.

Press and hold the

MODE

button again

for 3 seconds. A display with

at

the top will appear.

3.

Press the UP

or DOWN

buttons

to select the correct model code.

F18 = GXOF18G

4.

Press the

MODE

button one time to return to normal

operation and display. If the model code was changed:

•

the display will go blank momentarily, then display the

model code entered.

•

the display will then return to the set present time

display, and the blue indicator light will flash. The

control will have to be reprogrammed. See

Programming

the Control

.

NOTE:

If the control is left in any of the above diagnostic

displays, or a flashing display when setting time, hardness,

etc., it will revert back to the normal display in 4 minutes.

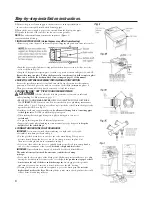

Service: Manually Initiated Electronics Diagnostics

SALT

LEVEL

SALT

LEVEL

SALT

LEVEL

Water meter

Valve

position

Position

switch

Motor

Motor

Turbine

Turbine support

and shaft

Sensor

housing

Position

switch

Valve

outlet

SALT

LEVEL

H45