22

CLEANING THE NOZZLE AND VENTURI ASSEMBLY

A clean nozzle and venturi is needed for the

water softening system to work properly.

This small unit makes the suction to move brine

from the salt storage area to the resin tank

during recharge. If it becomes plugged with

sand, dirt, etc., the water softening system will

not work and you will get hard water.

To get to the nozzle and venturi, remove the

water softening system top cover. Be sure the

water softening system is in service cycle (no

water pressure at nozzle and venturi). Then,

while holding the nozzle and venturi housing

with one hand, remove the cap. Lift out the

screen support and screen, then the nozzle

and venturi. Wash and rinse the parts in warm

water until clean. If needed, use a small brush

to remove iron or dirt. Also check and clean the

gasket.

NOTE:

Some models have a small flow plug

located in the nozzle and venturi, and/or a small

cone shaped screen in the housing. Be sure to

check and clean these parts, if your model is so

equipped.

Carefully replace all parts in the correct order.

Lightly lubricate the o-ring seal with clean

silicone grease or petroleum jelly and place in

position.

Install and tighten the cap, by hand

only. Do not overtighten the cap.

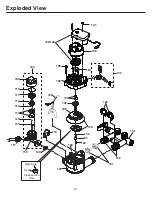

Nozzle and

Venturi

Cap

O-ring seal

Screen

support

Screen

Gasket

Screen

*Flow

plug

*Flow plug

Ferrule Nut

IMPORTANT:

Be sure small holes in the

gasket are centered directly over the small

holes in the nozzle and venturi housing.

* Install with numbered side up, concave side

down.

Routine Maintenance