H301/302 HSR Compressors | Rev. 2.2 | 25

Piston Head End and Crank End Clearance

The piston head end and crank end clearance is variable and determined by

the assembly of 10 or more parts depending upon the cylinder configuration.

Standard practice is to set the crank end piston clearance at 1/3 (but not less

than 0.040”) and head end clearance at 2/3 the summation of the head and

crank end clearances. Piston end clearance is measured by placing solder or

soft aluminum wire into the cylinder via an inlet port. Rotate crankshaft pushing

piston through stroke and crushing soft solder or aluminum wire. Use dial caliper

or 0-1” micrometer to measure crushed thickness of soft solder or aluminum

wire. Manually rotate the crankshaft several revolutions to assure no head end

interference. Monitor for abnormal vibration and/or knocking noise on startup

warm up. The CNG step cylinders having a concentric head end valve, set the

crank end piston clearance at 0.040 to 0.050”. CNG step cylinder piston head end

clearance measurement is difficult to achieve repeatable values and is, therefore,

not practical. Piston rod runout tolerance is 0.000 to 0.002” horizontal and 0.000 to

0.005” vertical measured with dial indicator.

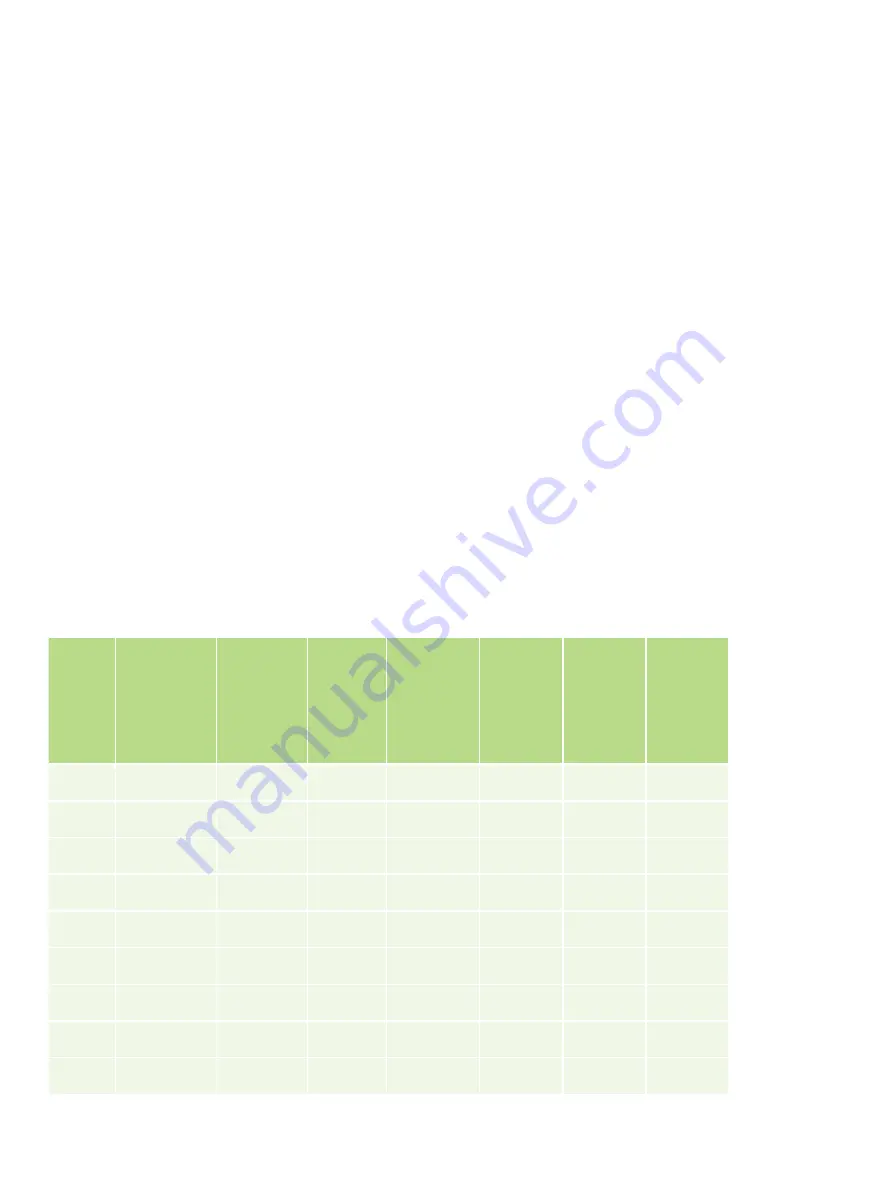

Cylinder Sizes, Bores, Piston Diameters, Clearance and

Weight

The H301/302 cylinder size, bore and piston diameter, clearance and weight of the

fixed clearance or VVCP assembly for lubricated cylinders are listed below.

Cylinder

size

inches

(mm)

Bore diameter

inches (mm)

Piston

diameter

inches (mm)

Clearance

inches

(mm)

Double

Acting

cylinder

assembly

estimated

weight

pounds (kg)

Tandem/

Stepped

cylinder

assembly

estimated

weight

pounds (kg)

VVCP

assembly

estimated

weight

pounds (kg)

Cylinder

head

estimated

weight

pounds (kg)

1.25

(31.75)

1.250 (31.750)

1.252 (31.801)

1.238 (31.445)

1.242 (31.547)

0.008 (0.203)

0.014 (0.356)

1.5

(38.10)

1.500 (38.100)

1.502 (38.151)

1.488 (37.795)

1.492 (37.897)

0.008 (0.203)

0.014 (0.356)

1.75

(44.45)

1.750 (44.45)

1.751 (44.4754)

1.730 (43.942)

1.732 (43.9928)

0.018 (0.4572)

0.021 (0.5334)

2

(50.8)

2.000 (50.8)

2.001 (50.8254)

1.980 (50.292)

1.982 (50.3428)

0.018 (0.4572)

0.021 (0.5334)

2.5

(63.50)

2.500 (63.500)

2.502 (63.551)

2.488 (63.195)

2.492 (63.297)

0.008 (0.203)

0.014 (0.356)

190 (86.182)

170 (77.110)

6 (2.721)

3

(76.20)

3.000 (76.200)

3.002 (76.251)

2.982 (75.743)

2.992 (75.997)

0.008 (0.203)

0.020 (0.508)

190 (86.182)

170 (77.110)

19 (8.618)

8 (3.628)

3.5

(88.90)

3.500 (88.900)

3.502 (88.951)

3.480 (88.392)

3.485 (88.519)

0.015 (0.381)

0.022 (0.559)

270 (122.469)

130 ( 58.967)

31 (14.061)

10 (4.535)

4

(101.60)

4.000 (101.600)

4.002 (101.650)

3.983 (101.170)

3.987 (101.270)

0.013 (0.330)

0.019 (0.480)

280 (127.005)

140 (63.502)

34 (15.422)

11 (4.989)

4.5

(114.30)

4.500 (114.300)

4.502 (114.350)

4.482 (113.840)

4.487 (113.970)

0.013 (0.330)

0.020 (0.507)

310 (140.613)

-

46 (20.865)

15 (6.803)

Summary of Contents for H301 Series

Page 1: ...High speed reciprocating compressors H301 and 302 series operating manual GE Oil Gas ...

Page 10: ......

Page 17: ...H301 302 HSR Compressors Rev 2 2 7 ...

Page 18: ......

Page 30: ......

Page 48: ......

Page 61: ...H301 302 HSR Compressors Rev 2 2 51 ...

Page 62: ......

Page 76: ......

Page 98: ......

Page 103: ...H301 302 HSR Compressors Rev 2 2 93 ...

Page 104: ......

Page 114: ...104 Chapter 8 Maintenance Figure 21 Effective rod extension amount pocket is open ...

Page 120: ......

Page 129: ......

Page 130: ......

Page 135: ...H301 302 HSR Compressors Rev 2 2 5 ...

Page 137: ......