15

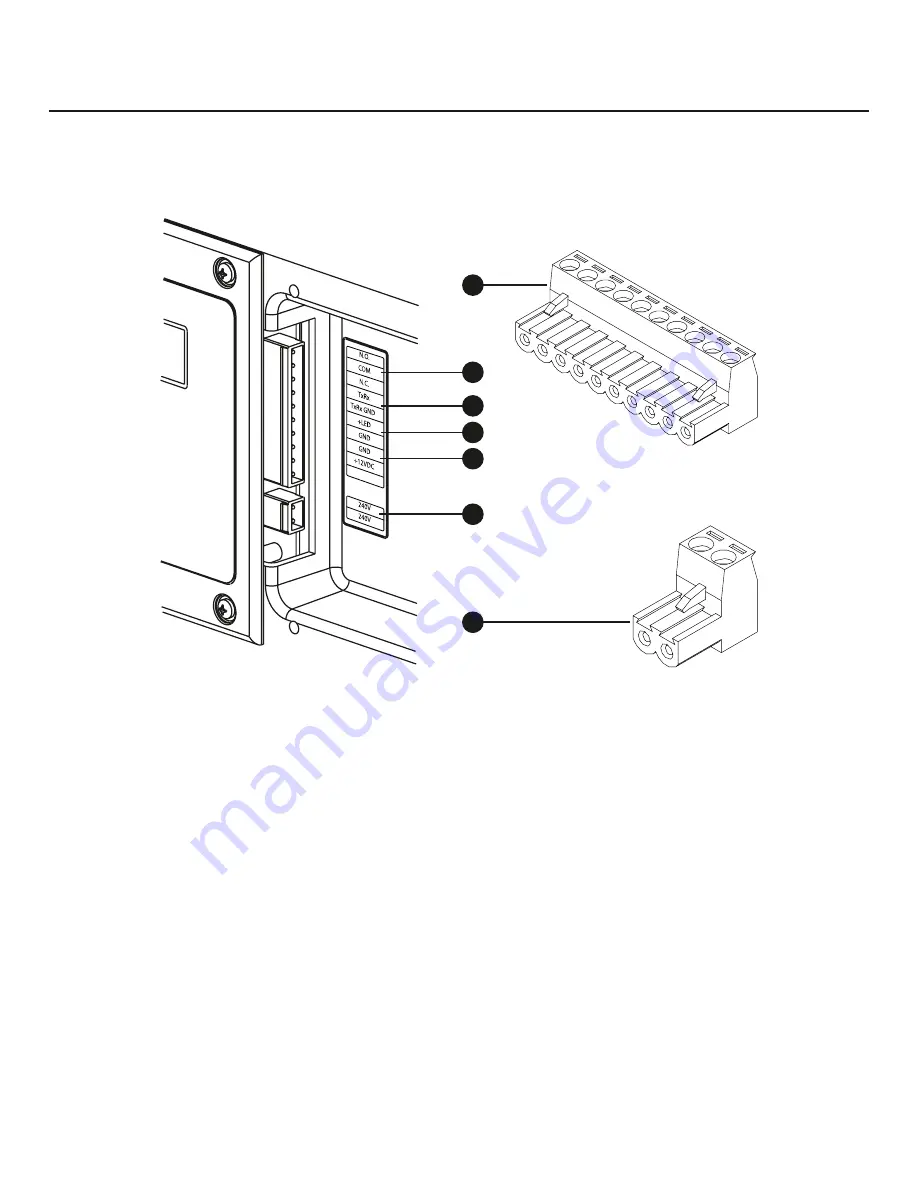

Low Voltage connections to signal fault contacts, transfer switch communication, remote LED and auxiliary 12VDC

power are made via a removable ten-pin connector plug. Compare this illustration with your generator to familiarize

yourself with the location of these connections. count down to the proper pin location on the control board because

visual alignment with the decal can be misleading.

system connectors

a – ten-pin connector Plug

B - fault contacts

— Use NO, COM and NC to hook up a

siren, light, etc. to alert you in case of a fault. Contacts

reverse state (NO goes to NC and vice versa) upon a

fault condition.

c - transfer switch communication

— Connect to transfer

switch control board for communication interface using

18AWG copper twisted pair wire.

D - remote LeD output

— Use this to hook up the remote

LED supplied with the generator. The remote LED will

turn on and off in a series of blinks if certain faults are

detected in the generator.

e - +12 Volt Dc, .5 amp output

— Internal auxiliary

power supply.

f - 240 Volt utility

— Use to hook up the 240V utility leads

from the transfer switch to the generator.

G – two-pin connector Plug

• For 12 kW power output connection, use #8 AWG minimum 300 volt 75°C-90°C copper wire, (ref. NEC Table 310.16,

100 ft. Use National Electric Code for correction factors and wire size calculations.)

• For 15 kW power output connection, use #6 AWG minimum 300 volt 75°C-90°C copper wire, (ref. NEC Table 310.16,

100 ft. Use National Electric Code for correction factors and wire size calculations.)

• For Utility Circuit connection use #14 AWG minimum 300 volt 75°C-90°C copper wire.

• For transfer switch communication use #18 AWG twisted pair conductors, no greater than 200 ft in length, 300 volt

75°C-90°C copper wire.

• When connecting to the connector plug(s), fasten only one wire to each connector screw.

• Torque connector plug screws to 7 in-lb (7.9 Newton meter).

C

E

D

A

B

F

G

Not

for

Reproduction