GEK-34054

Adjust the drag magnet to obtain a closing time as near as

possible to 1.31 seconds, but at least between 1.24 and 1.38 seconds.

The magnet should be approximately in the middle of its travel.

The

magnet is adjusted by loosening the nut under the magnet shelf.

Moving the magnet in decreases the time.

Moving the magnet out

increases the time.

When adjusting the drag magnet, be sure the outer edge of the

magnet never extends out beyond the cutout in the disk.

Be sure the

screw clamping the drag magnet to its supporting shelf is tight

before proceeding with other time checks.

Make sure the drag magnet

does not hit the counterweight at any position of the disk.

With the tap plug in the 2amp tap and the time dial at the No.

5

time setting,

check contact closing at 2 and 10 times tap value.

These closing times must be within the limits shown on Table

XV.

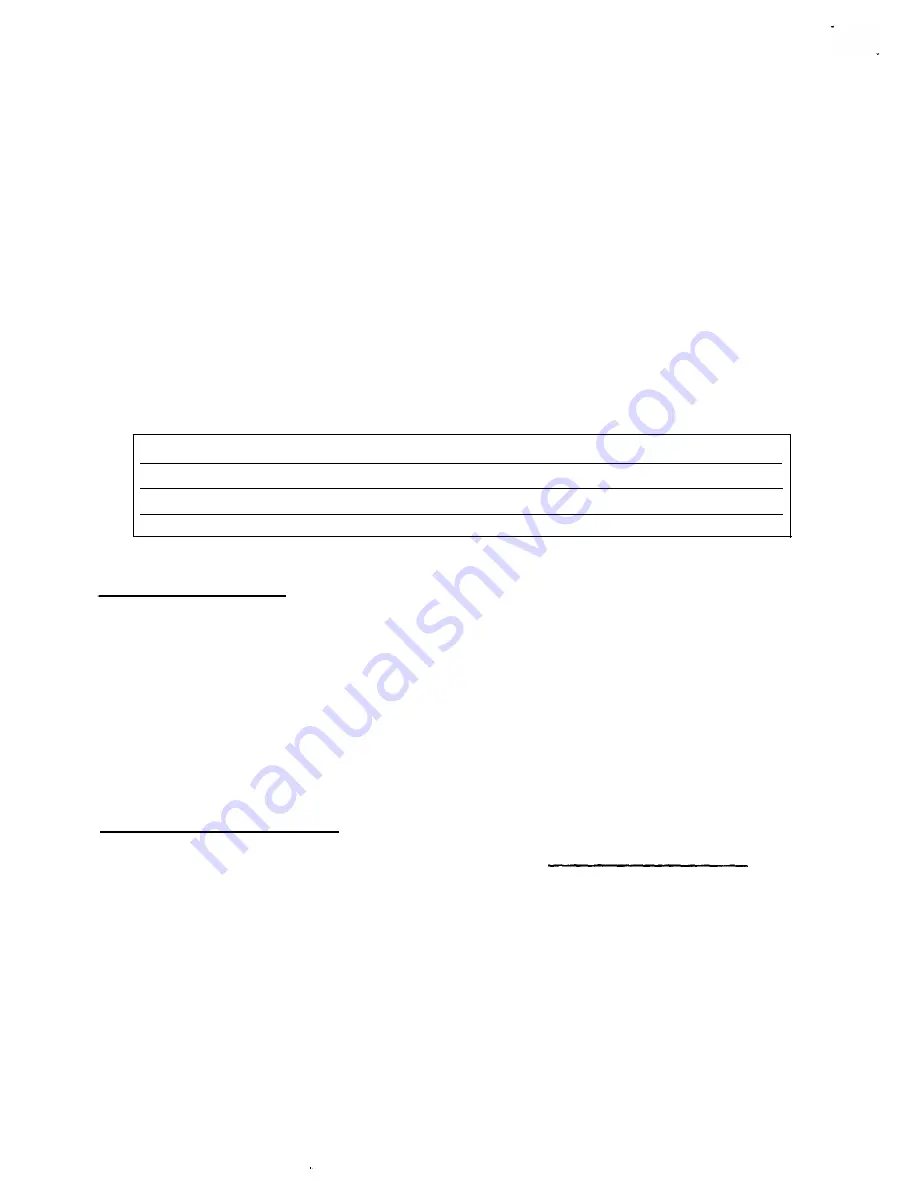

TABLE

XV

60HZ

TAP

AMPS

MIN .SEC.

MAX. SEC.

MIN. SEC.

2.0

4.0

6.70

7. 71

6.94

2.0

20.0

0.67

0.77

0.65

INSTANTANEOUS UNIT

1.

Both contacts should close at the same time.

50HZ

MAX. SEC.

7.98

0.75

2.

The backing strip should be so formed that the forked end (front)

bears against the molded strip under the armature.

3.

With the armature against the pole piece, the cross member of the

"T" spring should be in a horizontal plane and there should be at

least 1/32 inch wipe on the contacts.

Check this by inserting

a

0.012 inch feeler gage between the front half of the shaded pole

and the armature, with the armature held closed.

The contacts

should close with the feeler gage in place.

TARGET AND SEAL-IN UNIT

Check steps 1 and 2 as described under INSTANTANEOUS UNIT above.

To check the wipe of the seal-in unit, insert a 0.012 inch feeler

gage between the plastic residual of the armature and the pole

piece

with the armature held closed.

The contacts should close with the

feeler gage in place.

18

www

. ElectricalPartManuals

. com