GEH-1768

UNDERVOLTAGE RELAYS

TYPE IAV

INTRODUCTION

Thes e induction-dis k relays are actuated by a potential operating coil on a

laminated U-magnet.

The dis k s haft carries the moving contact that completes the

contact or contacts .

The disk s haft is res trained by a s piral s pring to give the

proper contact-closing voltage, and its motion 1.s retarded by permanent magnets

acting on the disk to give the correct time delay.

The s eal-in unit is mounted to the left of the s haft as s hown in Figure

1.

This unit has its coil in s eries and its contacts in parallel with the main contacts

s o that when the main contacts close, the s eal-in unit picks up and s eals in.

When

the s eal-in unit picks up, it raises a target into view that latches up and remains

exposed until released by press ing a button beneath the lower-left corner of the

cover.

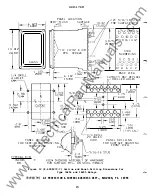

The relays are all mounted in s ingle-unit double-end cases .

The cas e has s tuds

for external connections at both ends .

The electrical connections between the relay

and the cas e are made through s tationary molded inner and outer blocks between which

res t a pair of removable connecting plugs that complete the circuit.

The molded

outer blocks carry the s tuds for the external connections , while the inner blocks

carry the terminals for the internal connections .

The operating coil is connected

in parallel with both the upper and the lower inner molded blocks, and the trip

circuit is connected in s eries with thes e blocks .

In this way, ins ertion of either

the upper or lower connecting plug will energize the operating coil, but the trip

circuit will not be completed until the s econd connecting plug is ins erted.

For

relays that have contacts clos ed when the relay is de-energized but open under

normal operating conditions , the double-connecting-plug feature allows the relay

contacts

to open before the trip circuit is

completed,

thus

mJ.nl.ml.ZJ.ng the

pos s ibility of incorrect tripping when returning the relay to s ervice after tests

and ins pection.

APPLICATION

Thes e relays are protective devices des igned to clos e trip or alarm circuits

whenever the voltage applied to their operating coils des cends to s ome pre

determined value.

The functions are des cribed in greater detail in the following

paragraphs.

OPERATING CHARACTERISTICS

The Type IAV54E relay has a s ingle circuit-clos ing contact that closes when the

voltage is reduced to s ome predetermined value; thus , the contacts are clos ed at

zero

volts .

This

relay

is

a

time undervoltage

relay

with

invers e

time

characteris tics , s hown in Figure 2.

3

www

. ElectricalPartManuals

. com