GEK-49822

.

AND SEAL

-

IN UN

I T

The rating and impedance of the seal-in unit for the 0.2 and 2 ampere taps are given

in Table 7.

The tap setting used will depend on the current drawn by the

The 0.2 ampere tap is for use with trip coils which operate on currents ranging

0.2 up to 2.0 amperes, at the minimum control voltage.

If this tap is used with trip

coils requiring more than two amperes, there is a possibility that the resistance of

seven ohms will reduce the current to so low a value that the breaker will not be

tripped.

The two ampere tap should be used with trip coils that take two amperes or more at

minimum control voltage, provided the current does not exceed 30 amperes at the maximum

control voltage. If the tripping current exceeds 30 amperes, the connections should

arranged so that the induction unit contacts will operate an auxiliary relay,

in

turn energizes the trip coil or coils.

On such an application, it may be necessary to

connect a loading resistor in parallel with the auxiliary relay coil to allow enough

current to operate the target seal-in unit.

CONTACTS

The current-closing rating of the induction unit is 30 amperes for voltages not

exceeding 250 volts. Their current-carrying rating is limited by the tap rating of the

seal-in unit.

*

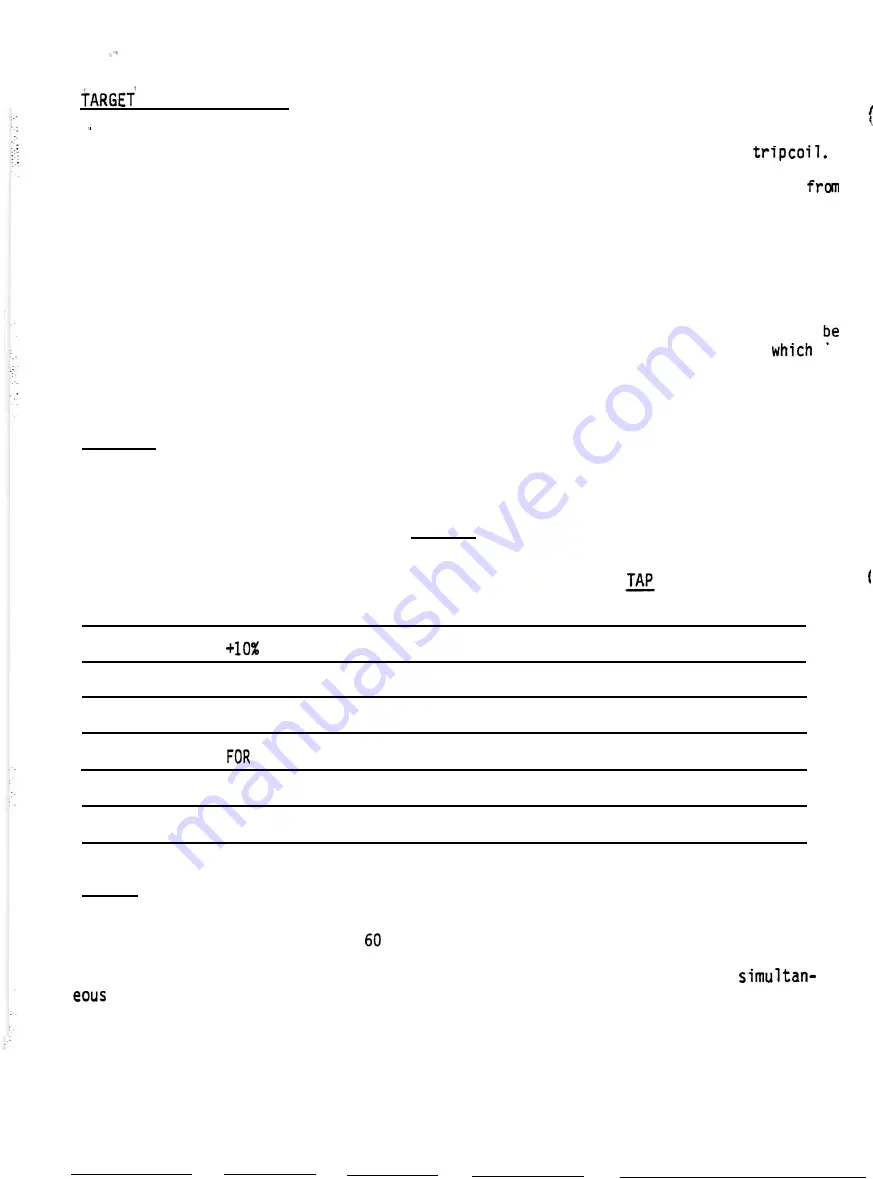

TABLE 7

SEAL-IN UNIT RATINGS

0.2

2.0

DC RESISTANCE

(OHMS)

8.3

0.24

MIN OPERATING (AMPERES) +0-25%

0.2

2.0

CARRY CONT. (AMPERES)

0.37

2.3

CARRY 30 AMPS

(SEC.)

0.05

2.2

CARRY 10 AMPS FOR (SEC.)

0.45

20

60 Hz IMPEDANCE (OHMS)

50.0

0.65

PICKUP

When potential polarized, the directional unit will pick up at 3.6 volts-amperes

at the maximum torque angle of degrees lag (current lags voltage). When current

polarized, it will pick up at approximately 0.5 ampere with the operating and

polarizing coils connected in series.

The performance of the unit with

l

current and potential polarization is typified in Fig. 13.

*Indicates Revision

8