GEK-49849

Wi th the contacts just c l os i ng at No . 0 t i me sett i ng, there shou l d be suff i c i ent

gap between the stat i on ary contact brush and i ts meta

1

back i ng str i p to ensure

approx i mate l y 1 /32 i nch wipe .

Current

The m i n i mum current at whi ch the t i me overcurrent u n i t wi l l c l ose i ts contacts i s

determ i ned by the pos i t i on of the p l ug i n the t ap bl ock . The t ap p l ate on thi s bl ock i s

marked i n amperes, as shown i n T abl es 3, 4 and 5 .

When the tap sett i ng i s changed wi th the rel ay i n servi ce, t he fol l owi ng procedure

must be fo l l owed:

( 1 ) Remove the connect i ng p l ug; thi s de-energ i zes the re l ay and

shorts the current transformer secondary wi n d i n g . ( 2 ) Remove the tap screw and p l ace

i t i n the tap mark ed for the des i red p i ckup current . ( 3) Rep l ace the connect i ng p l u g .

The m i n i mum current requ i red t o rotate the d i sk s l owly and t o c l ose the contacts

s hou l d be wi thi n f i ve percent of the val u e marked on the tap p l ate for any t ap sett i ng

and t i me d i al pos i ti on . I f thi s adjustmen t has been d i sturbed, i t can be restored by

means of the spr i ng adju s t i ng r i ng . The r i ng can be turned by i nser t i n g a screw dr i ver

bl ade i n the notches around the edge . By turn i ng the r i n g, the oper at i ng current of the

u n i t can be brought i nto agreement wi th the tap setti ng emp l oyed. Thi s adju stment al so

perm i ts any des i red sett i ng to be obt a i ned i ntermed i ate l y between the avai l abl e tap

setti ngs .

P i ckup adju stment by mean s of the control spr i ng app l i es to the JBCG5 1 and JBCG53

re l ays .

A

d i fferent procedure app l i e s to the JBCG77 r e l ays . For the JBCG77 rel ays,

the p i ckup of the u n i t for any current t ap sett i ng i s adju sted by means of the var i abl e

res i stor i n the phase- shi ft i ng c i rcu i t .

Thi s adjustmen t a l so perm i ts any des i red

sett i ng i ntermedi atel y between the var i ous t ap sett i ng s to be obtai ned. The control

spr i ng i s prewoun d approx i mate l y 660 degrees wi th the contacts just c l ose d . F urther

adju stment of thi s sett i n g i s sel dom requ i red; if i t i s requ i red, because of the

i n suff i c i ent range of the var i abl e res i s tor, i t shou l d never be necessary to w i n d up

the control spr i ng adju ster more than 30 degrees {one n otch) or unwi n d i t more than 90

degrees ( three notches ) from the factory sett i n g .

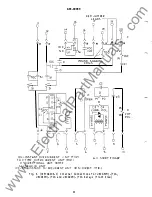

Test connec t i ons for mak i ng p i ck u p and t i me check s o n the t i me over-current u n i t

are shown i n F i g . 2 1 . U se a source of 120 vo l ts o r greater wi th good wave form and

constant frequency . Stepdown transformers or phantom l oads shou l d not be emp l oyed i n

test i ng i nduct i on rel ays s i nce the i r use may cause a d i storted wave form. The contact

i n the wound shad i ng coi l c i rcu i t marked

D,

see i ntern al connect i on d i agram, mu st be

b l ocked c l osed or jumpered for both the p i ck u p test and the t i me tes t .

T i me

The sett i ng of the t i me d i a l determ i nes the l ength of t i me the u n i t requ i res to

c l ose i ts contacts when the current reaches a predeterm i ned va l ue . The contacts are

just c l osed when the d i al i s set on zero. When the d i al i s set on 10, the d i sk must

travel the max imum amount to c l ose the contacts and therefore thi s sett i ng g i ve s the

max i mum t i me setti n g .

19

www

. ElectricalPartManuals

. com