GEK-49849

CONNECTIONS

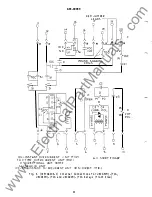

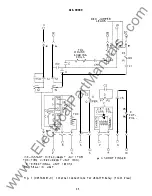

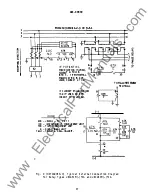

The internal connection diagrams for the various relays are shown in Fig. 5 to

7. Typical wiring diagrams are shown by Fig. 8 and

9.

Unless mounted on a steel

panel which adequately grounds the relay case, it is recommended that the case be

grounded through a mounting stud or screw with a conductor not less than #12 B&S

gage copper wire or its equivalent.

INSPECTION

At the time of installation, the relay should be inspected for tarnished

contacts, loose screws, or other imperfections. If any trouble is found, it should

be corrected in the manner described in the section on

SERVICING.

CAUTION

Every circuit in the drawout case has an auxiliary brush.

It is especially

important on current circuits and other circuits with shorting bars that the

auxiliary brush be bent high enough to engage the connecting plug or test plug

before the main brushes do.

This will prevent CT secondary circuits from being

opened. Refer to Fig. 20 .

OPERATION

Before the relay is put into service, it should be given a check to determine

that factory adjustments have not been disturbed. The time dial will be set at zero

before the relay leaves the factory. If the setting has not been changed, it will

be necessary to change this setting in order to open the time overcurrent unit

contacts. The following tests are suggested:

TARGET AND SEAL-IN UNIT

1 .

Make sure that the tap screw is in the desired tap.

2 .

Perform pickup and dropout tests as outlined in the ACCEPTANCE TESTS

section.

TIME OVERCURRENT UNIT

1 .

Set tap screw on desired tap.

Using the test circuit in Fig. 21, apply

approximately twice tap value current until the contacts just close.

Reduce the current until the light in series with the contacts begins to

flicker. This value of current should be within five percent of tap value.

2 .

Check the operating time at some multiple of tap value. This multiple of

tap value may be five times tap rating or the maximum fault current for

which the relay must coordinate. The value used is left to the discretion

of the user.

DIRECTIONAL UNIT

1 .

If current polarized or dual polarized, connect per Fig. 22 .

2 .

Adjust the control spring for 0 . 5 ampere pickup (front contacts)

3 .

If potential polarized connect per Fig. 23.

4.

With voltage set at 5 volts at terminals

9

& 10, adjust the control spring

so that the unit closes its front contacts at 1 . 4 ±20% Amperes.

2 2

www

. ElectricalPartManuals

. com